Replaceable adhesive tape and its application method

A replaceable, adhesive strip technology, applied in the direction of winding strips, shafts and bearings, layered products, etc., to achieve the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

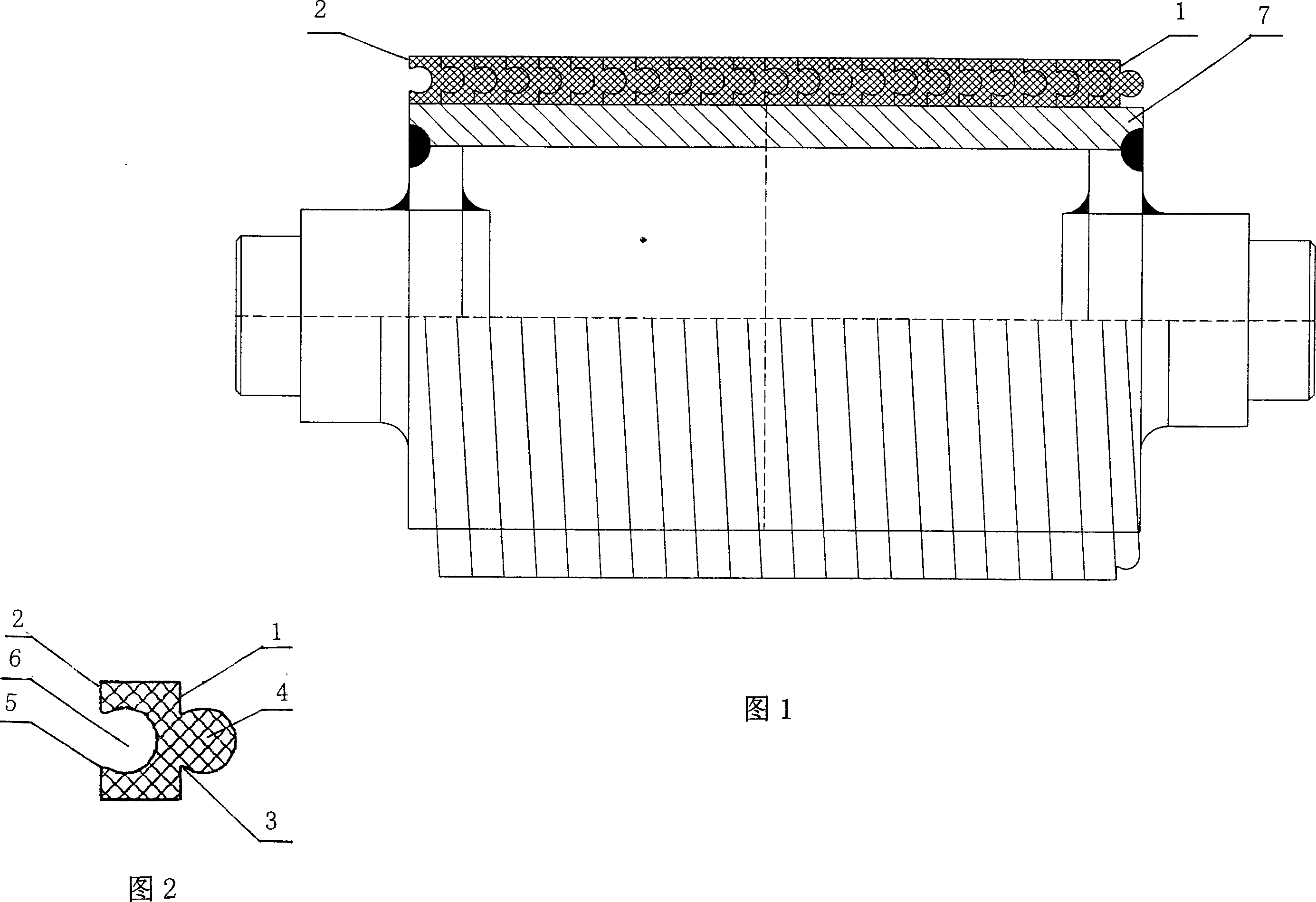

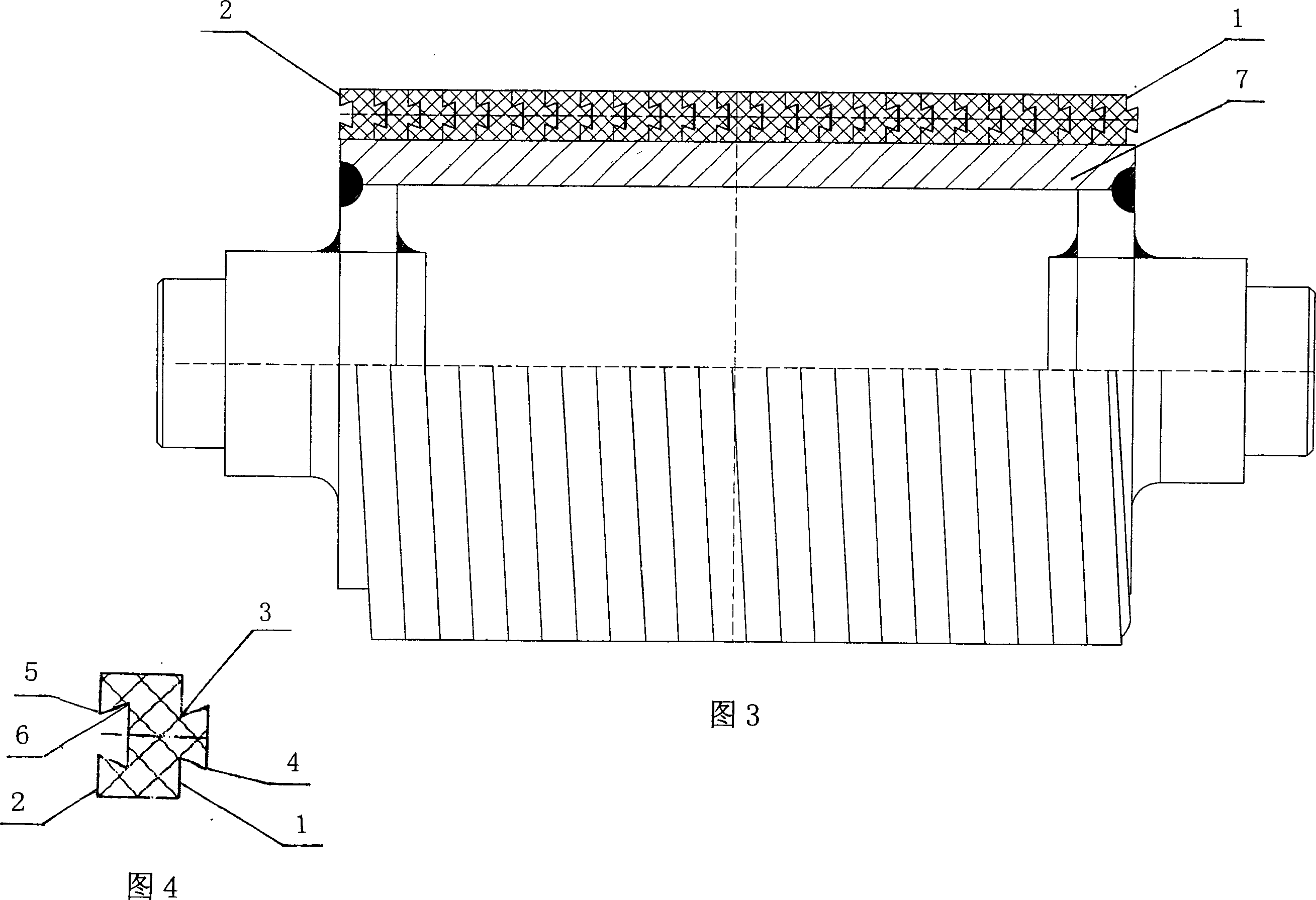

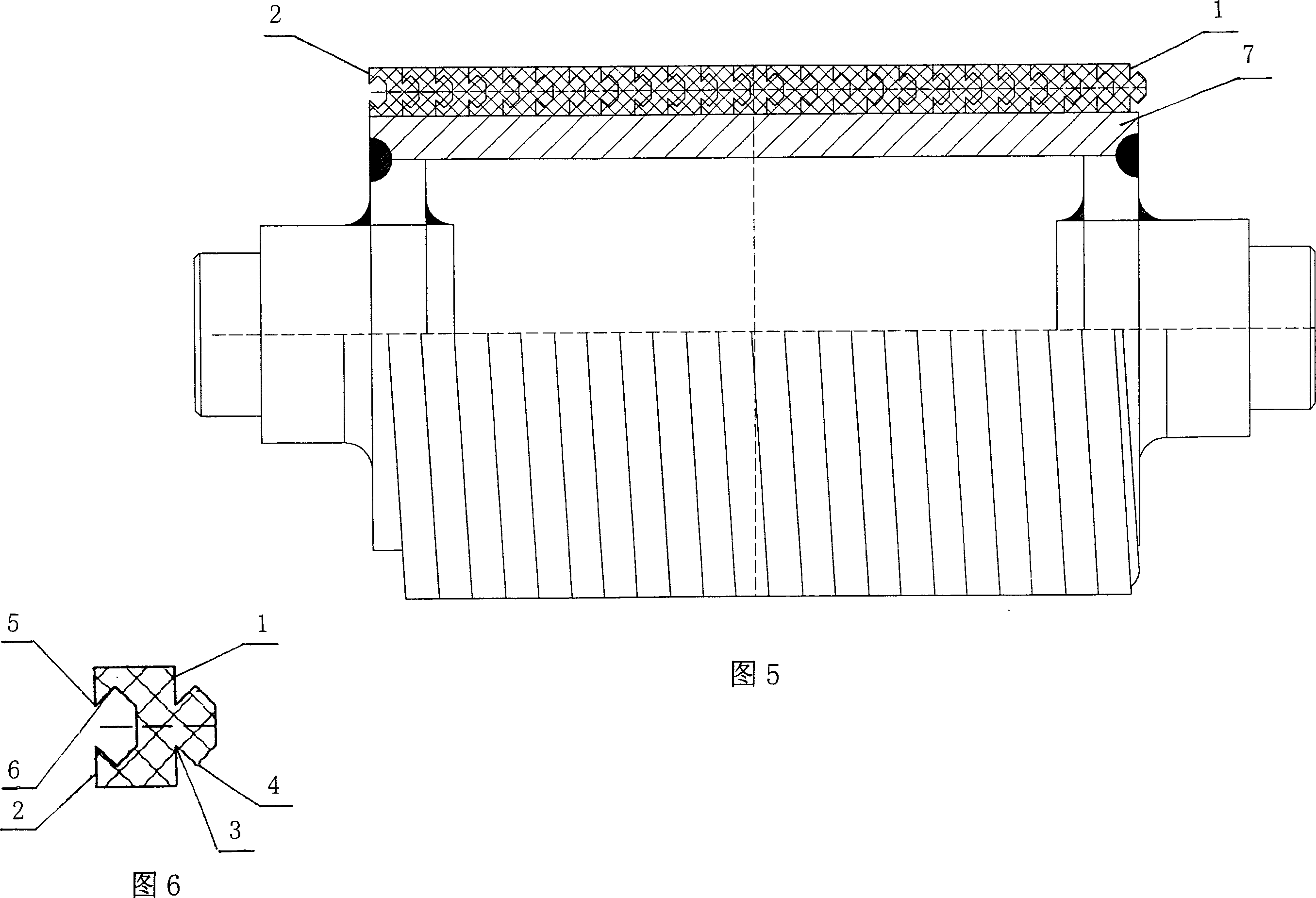

[0018] In Fig. 1, on the outer diameter of the rubber roller mandrel 7, there are beading strips closely arranged in a helical shape. The left and right convex surfaces 1 and concave surfaces 2 of the cross section of the beading strips are Ω-shaped with the same projection, and the cross section of the beading strips is parallel to each other. The beginning and end of the beading strip are fixedly bonded on the outer surface of the mandrel 7 . Beading strip also can be fixed on the outer surface of mandrel 7 with nail or by screw. The root 3 of the Ω-shaped protrusion and the entrance 5 of the Ω-shaped groove are smaller than the front 4 of the Ω-shaped protrusion and the inside 6 of the Ω-shaped groove, so the adjacent beading strips have a self-locking function during work, which can resist It will not crack under the action of external force. To facilitate winding, the root 3 of the protrusion and the entrance 5 of the groove on the convex surface 1 may be slightly small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com