Giant frame structure

A technology of giant frame and main frame, applied in the direction of building type, building components, building structure, etc., can solve the problem of difficult to repair the plastic damage of the main structure, and achieve the effect of reducing the earthquake response, improving the seismic toughness, and protecting the plastic damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention provides a giant frame structure including a self-resetting substructure. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

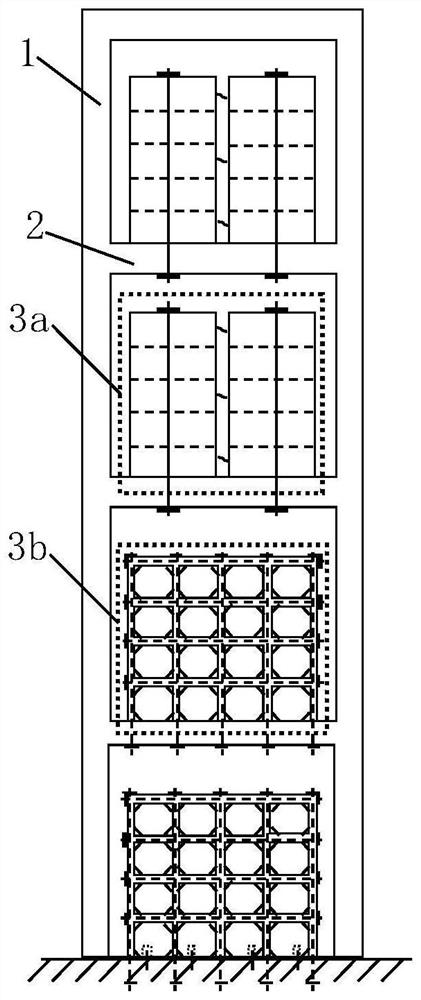

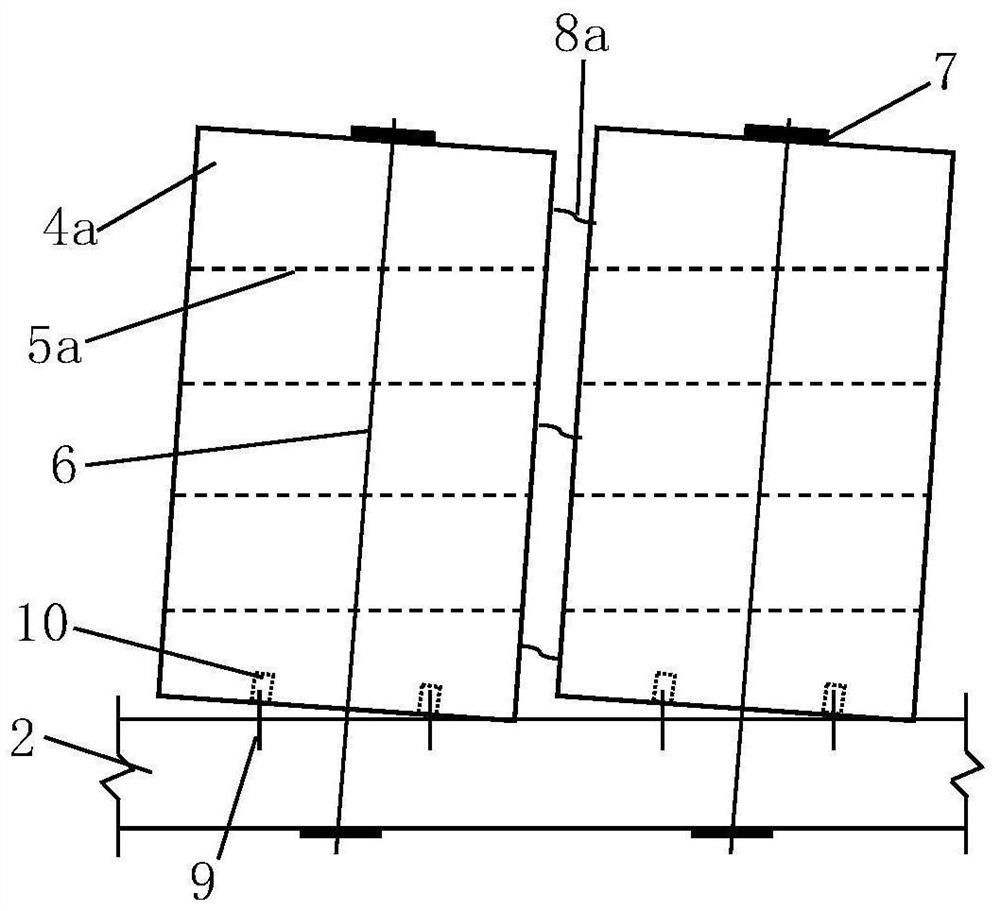

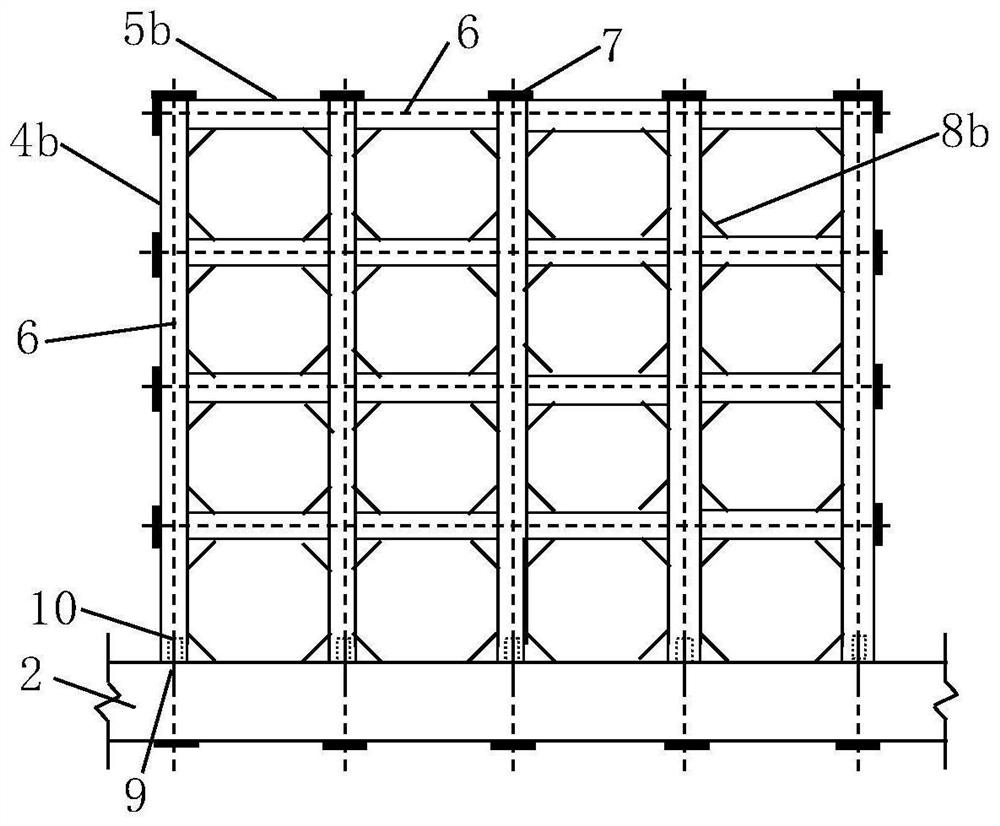

[0021] As shown in the figure, this embodiment provides a mega frame structure, including main frame columns 1, main frame beams 2, and self-resetting substructures 3a, 3b. The self-resetting substructures 3a, 3b are installed on the main frame beam 2; the self-resetting substructures 3a, 3b include energy consumption parts 8a, 8b and self-resetting parts 6, and the energy consumption parts 8a, 8b are used To make the self-resetting substructures 3a, 3b dissipate seismic energy before the main frame column 1, main frame beam 2 and other main structures, thereby reducing the seismic response of the main structure and protecting the main structure from plastic damage; The reset member 6 is used for quick reset after lateral deformation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com