Endoscope delivery window system

A transfer window and endoscope technology, applied in the field of medical devices, can solve the problems of bacterial growth, easy drying and cleaning of dirt, and inability to keep the endoscope wet, so as to prevent cross-infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

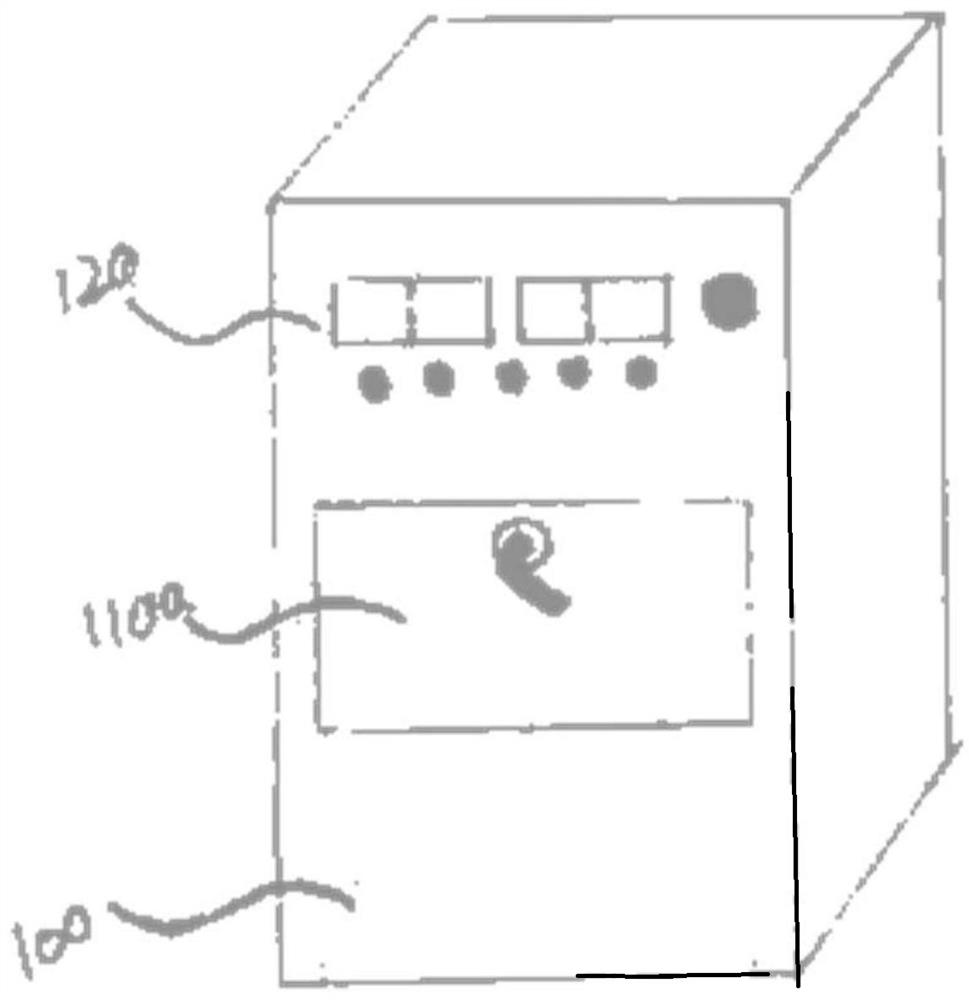

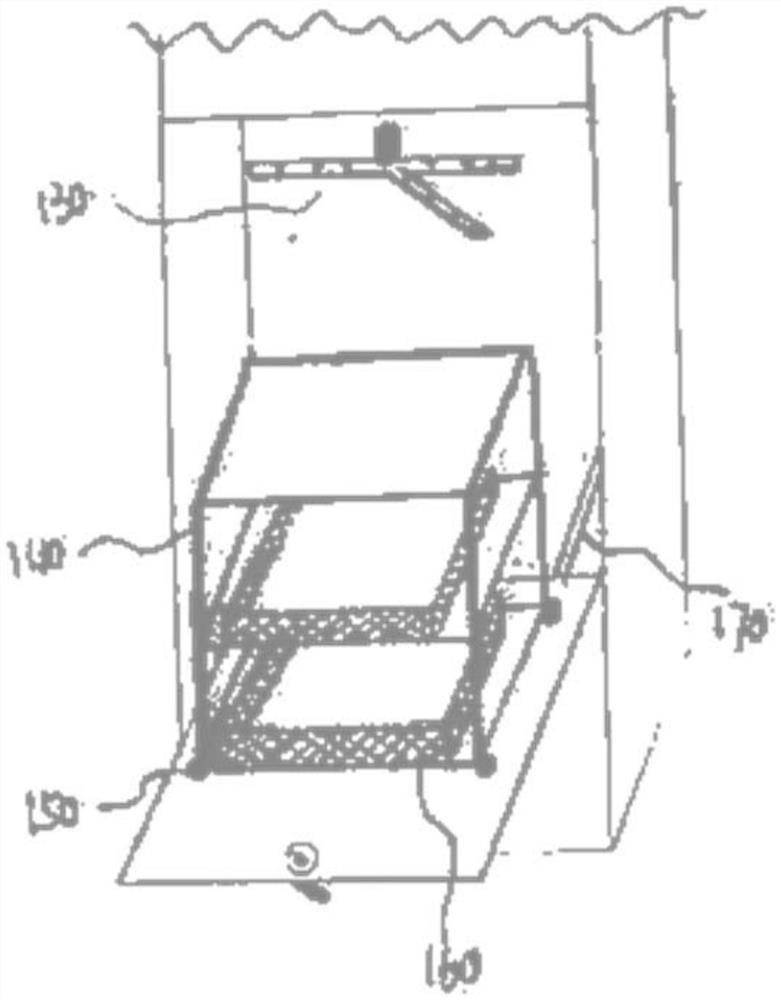

[0035] An endoscopic transfer window system such as Figure 1-3 , the system includes: a transfer window body 100 for placing an endoscope; a spraying device for keeping the inside of the transfer window body 100 moist and self-thermal disinfection; a thermal drying device for keeping the inside of the transfer window body 100 dry ; The spraying device and the thermal drying device are designed through different circuits and cannot coexist. The transfer window body 100 also includes a window door for putting in and taking out the endoscope. The transfer window body 100 is provided with a cleaning rack 140 , and the cleaning rack 140 is provided with a cleaning tray 160 on which the endoscope is placed. The cleaning frame 140 and the cleaning tray 160 are made of stainless steel, and the cleaning tray 160 can be taken out separately. A pulley 150 is provided under the cleaning rack 140 , and a slide rail 170 matching the pulley 150 is provided in the transfer window body 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com