Refrigerant transmission coupling device test system

A technology of coupling device and testing system, which is applied in the direction of measuring device, testing of mechanical parts, testing of fluid tightness, etc., can solve problems such as unsatisfactory, unusable, and unsuitable for the internal leakage rate test of refrigerant transmission coupling device, and achieve Improve work efficiency, save time, and facilitate assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

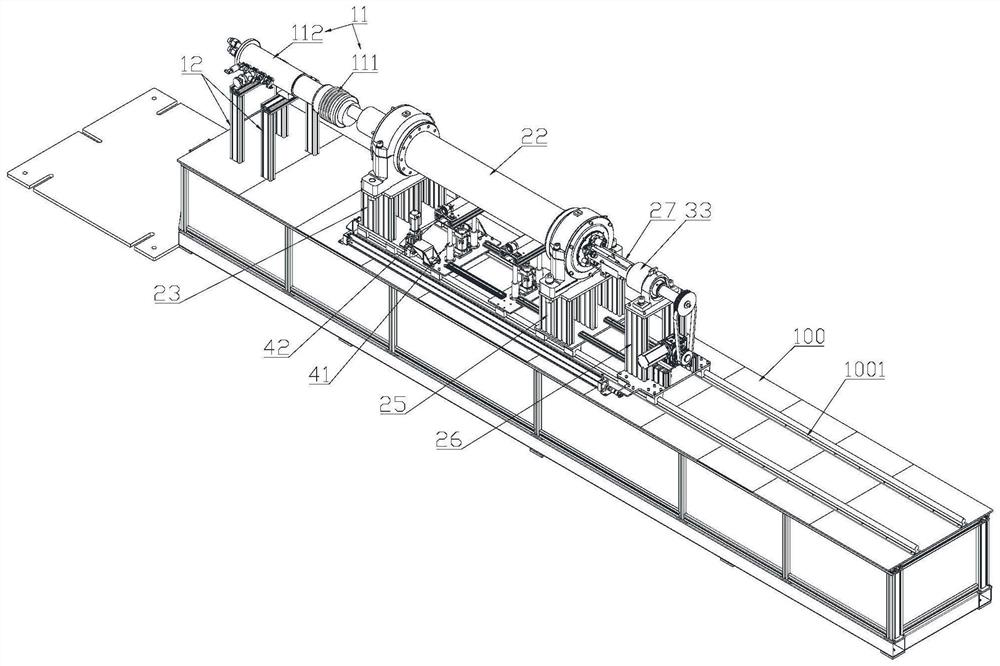

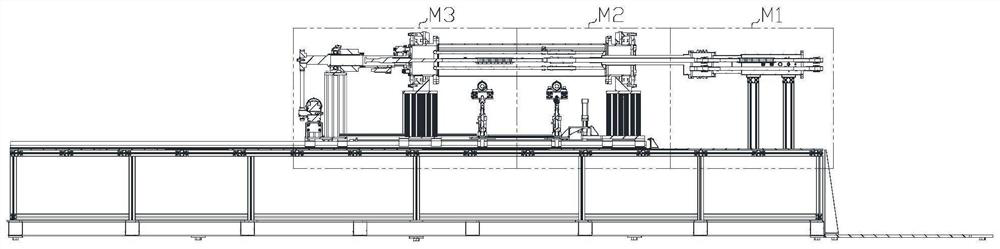

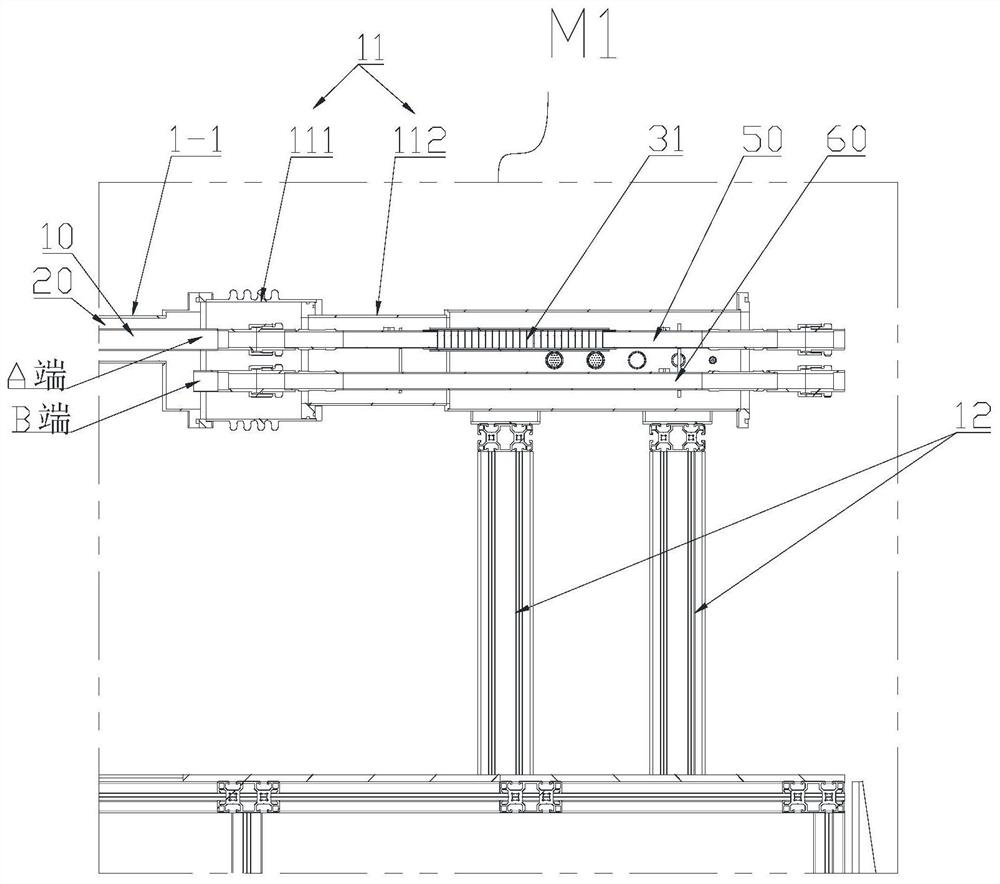

[0054] This embodiment discloses a test system for a refrigerant transmission coupling device, such as image 3 , Figure 4 As shown, the refrigerant transmission coupling device includes a stationary assembly 1-1 and a rotating assembly 1-2, the stationary assembly 1-1 is coaxially sleeved in the rotating assembly 1-2; the stationary assembly 1-1 is provided with a first refrigerant passage 10 and The second refrigerant passage 20, the first refrigerant passage 10 is an intake passage, the second refrigerant passage 20 is a return air passage, and the second refrigerant passage 20 is an annular passage sleeved outside the first refrigerant passage 10, and the first refrigerant passage 10 is an annular passage. 10 coaxial.

[0055] The test system includes a first vacuum chamber and a second vacuum chamber;

[0056] Such as figure 1 As shown, in this embodiment, the first vacuum chamber includes a first vacuum tube 11 and a third support 12; the first vacuum tube 11 include...

Embodiment 2

[0068] Such as Figure 5 As shown, in this embodiment, on the basis of implementing 1, in the second vacuum tube 22, two stabilizing rods 29 are also fixed, and the two straight pipes 402 are respectively fixed by the stabilizing frame and the stabilizing rod 29 at the corresponding position, further improving The stability of the straight pipe 402 is improved, and the vibration is reduced.

Embodiment 3

[0070] On the basis of Embodiment 1 and Embodiment 2, in this embodiment, a rail 1001 is provided on the workbench 100; the first bracket 23, the second bracket 25, and the fourth bracket 36 are slidably fixed on the rail 1001.

[0071] After disassembling the bellows, remove the internal pipeline joints, slide the first bracket 23, the second bracket 25, and the fourth bracket 36, and then the stationary component can be pulled out from the rotating component, so that the test system can be rotated without disassembly The overall movement of the end realizes the fast and convenient sample change of the sample to be tested;

[0072] Simultaneously, the second vacuum tube 22 is released from the fixed relationship with the first bracket 23, and the second bracket 25 and the fourth bracket 36 are slid to drive the second vacuum tube 22 and all parts fixed with the second bracket 25 and the fourth bracket 36. Move, so that the pipelines in the second vacuum chamber are exposed, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap