Backlight module and display module

A backlight module and backplane technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as large frame width, achieve ultra-thin cost, improve backlight effect, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to enable those skilled in the art to better understand the technical solutions of the present invention, a backlight module and a display module of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

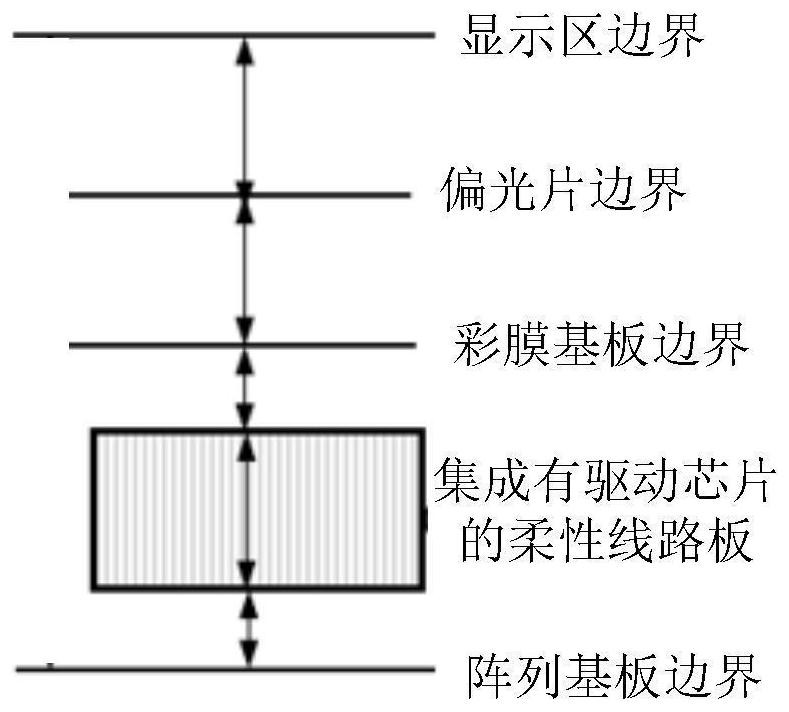

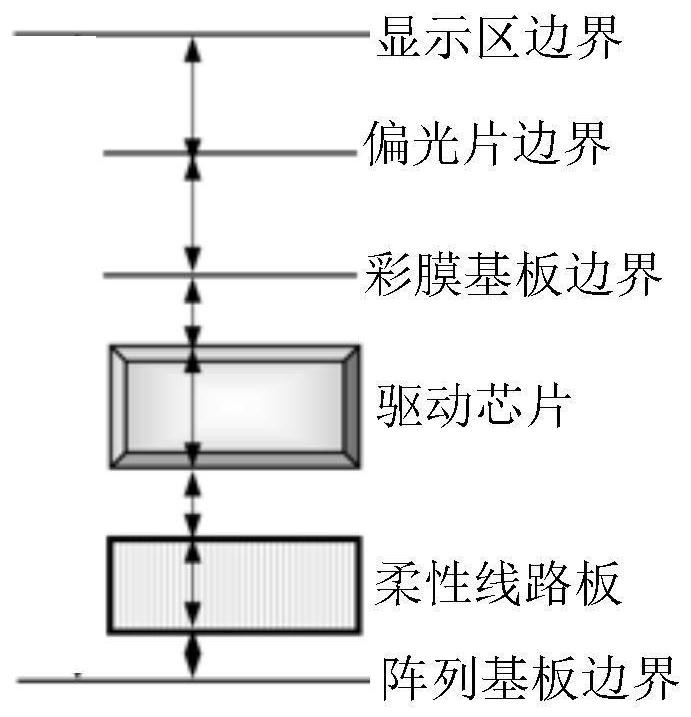

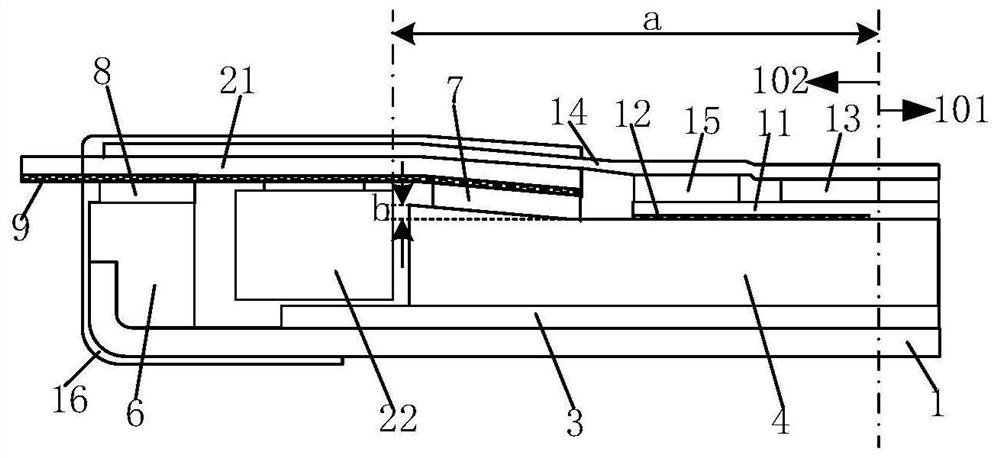

[0072] Currently, refer to Figure 3-Figure 5 , the COG+ backlight module is equipped with the premise that the width of the frame area 102 of the backlight module is narrowed to less than 3.0mm, and the backlight module needs to be ultra-thin. The backlight includes lamp beads 22 and circuit substrates 21 electrically connected to the lamp beads 22; The light-emitting surface of the backlight module lamp bead 22 in the backlight is facing the edge end surface of the light guide plate 4 (i.e., the light incident surface). The smooth side adopts a wedge-shaped flare design, and the other areas of the light guide plate 4 adopt a flat design. The wedge-shaped bell mouth design will...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com