Rotor baffle assembly, motor and industrial ceiling fan

A baffle assembly and rotor technology, which is applied to electric components, magnetic circuit rotating parts, electrical components, etc., can solve problems such as core teeth warping, and achieve the effect of ensuring quality and preventing warping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

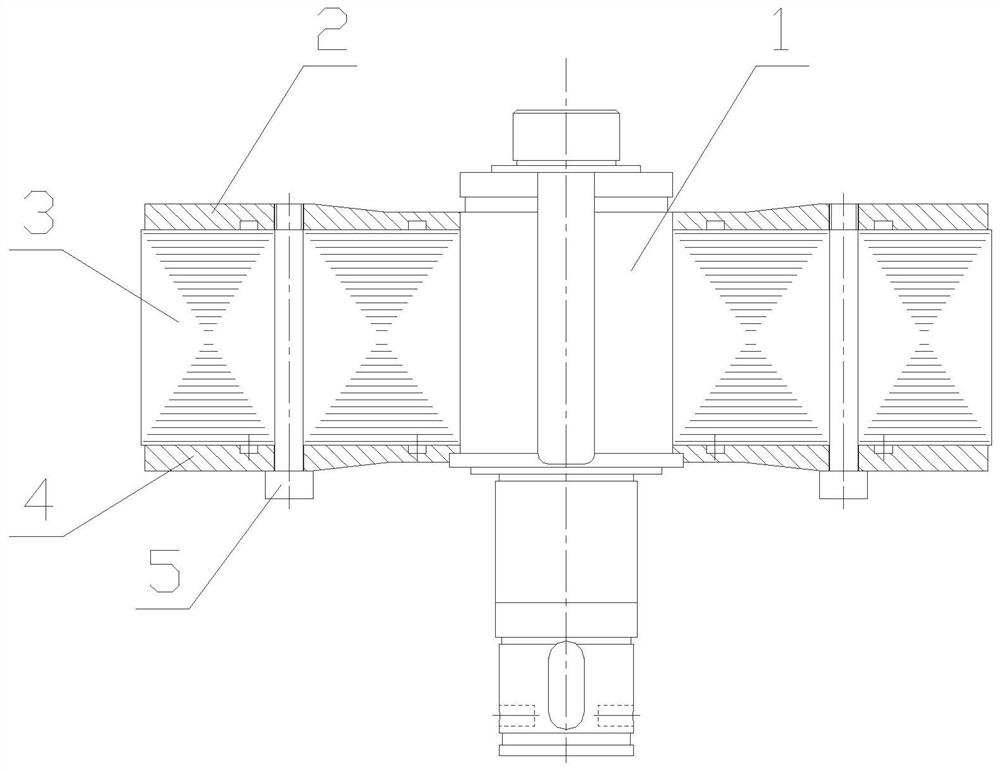

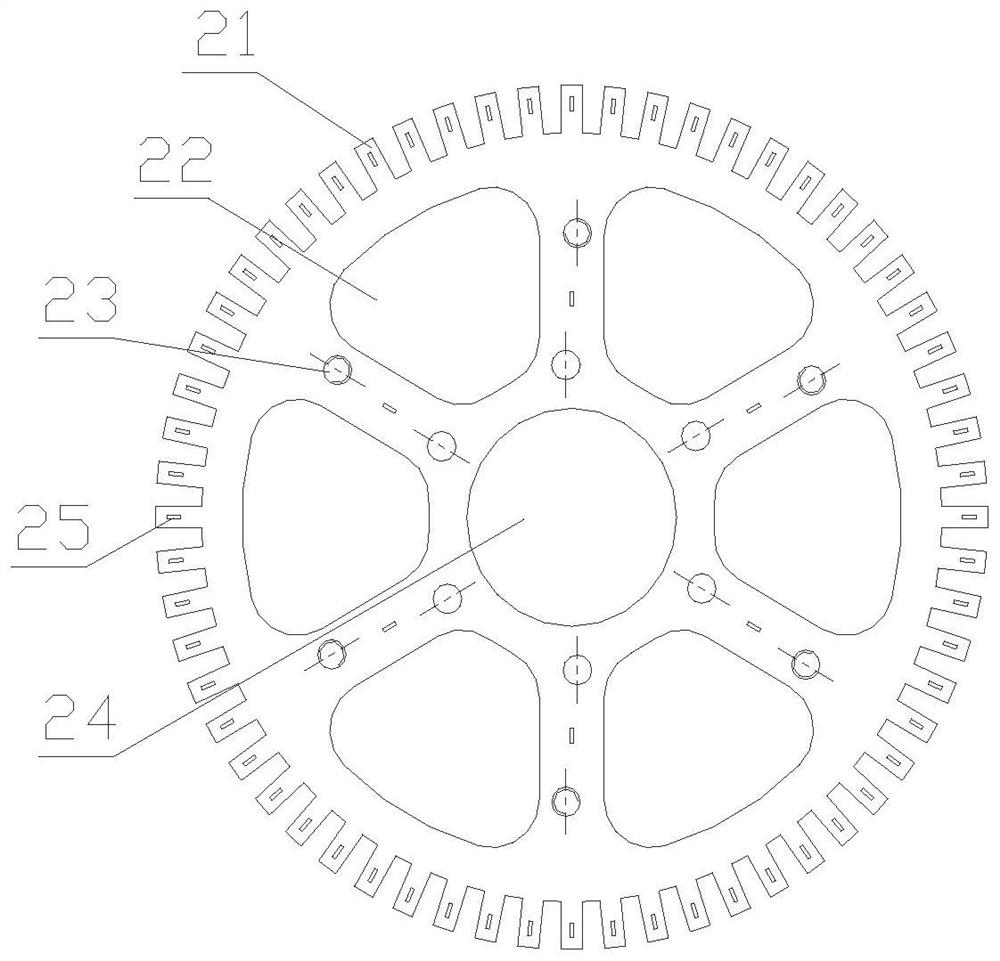

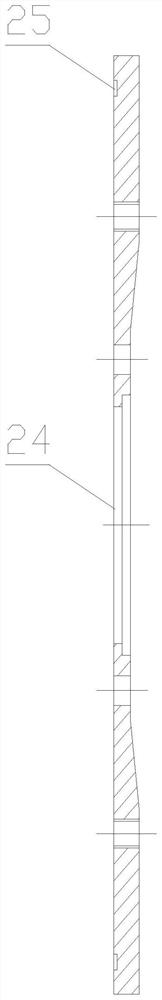

[0024] see in conjunction Figure 1 to Figure 4 As shown, according to an embodiment of the present application, a rotor baffle assembly includes:

[0025] The baffle body is set close to the rotor core 3; the baffle body is ring-shaped and includes teeth;

[0026] The tooth portion is provided with a plurality of first teeth 21 , and the plurality of first teeth 21 are evenly distributed on the outer periphery of the baffle body and abut against the slots of the rotor teeth 31 of the rotor core 3 .

[0027] The first tooth 21 is arranged on the outer periphery of the rotor baffle body, and the first tooth 21 directly abuts against the groove of the rotor tooth 31, thereby realizing the alignment between the baffle body and the rotor core 3, and the first tooth 21 and the magnetic steel 34 in the groove of the rotor tooth 31. Blocking can prevent the rotor iron core 3 from warping and ensure the quality of the rotor iron core 3 .

[0028] For the small iron core of the magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com