Universal rolling mill with structure for preventing pull rod of guide and guard beam from warping in roll changing process

A universal rolling mill and guide beam technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of tedious installation and debugging of roll system, time-consuming and laborious, low efficiency, etc. The tilting head of the Weiliang tie rod improves the effect of maintenance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

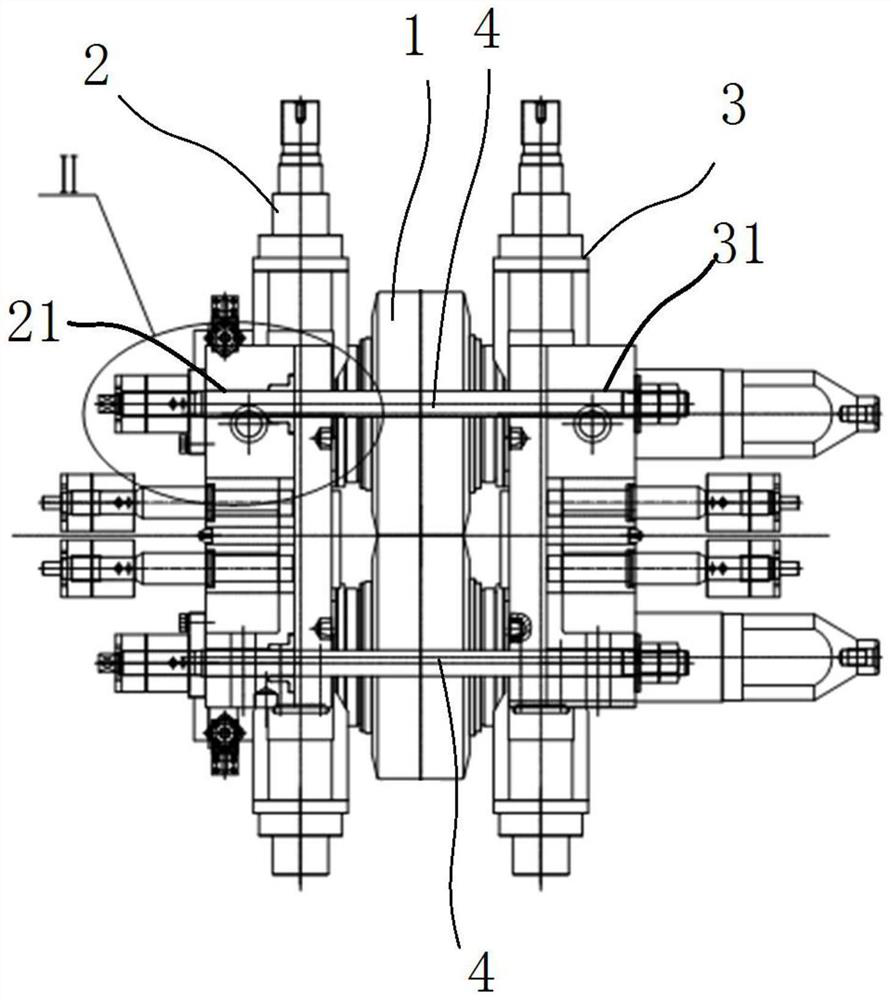

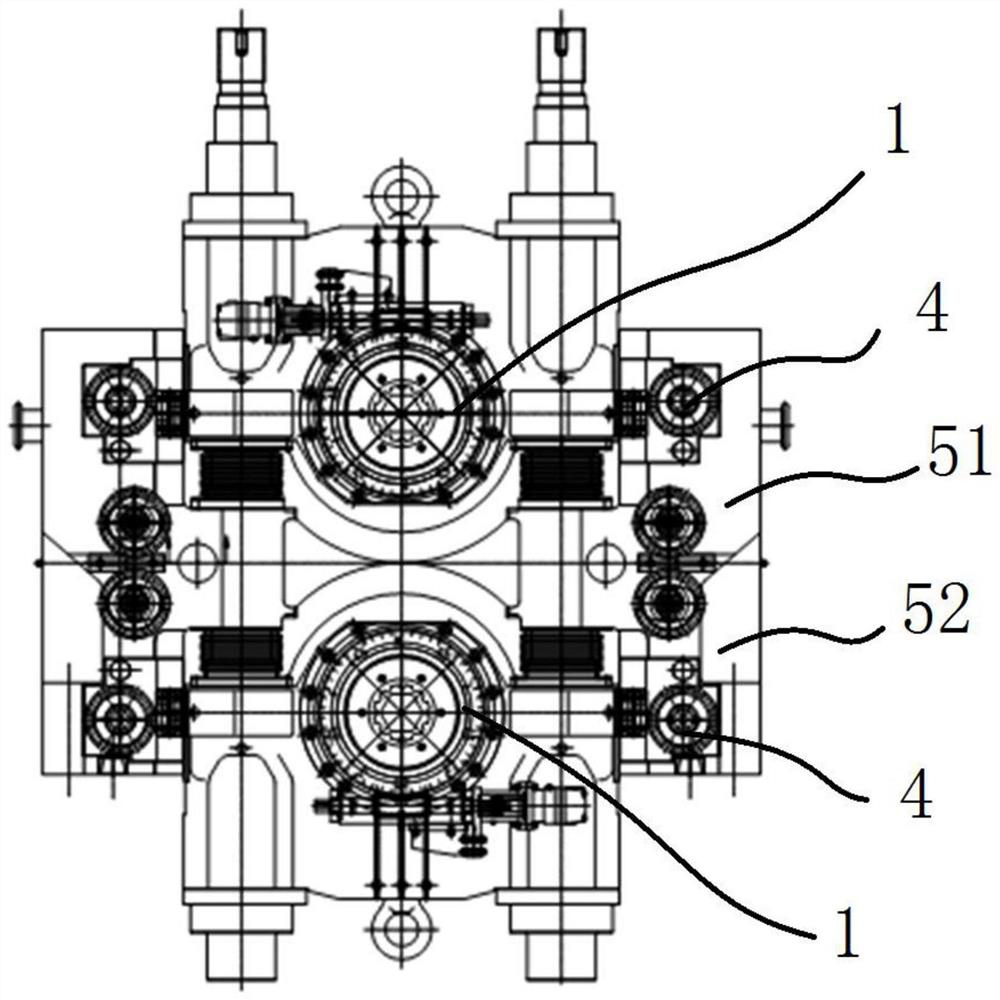

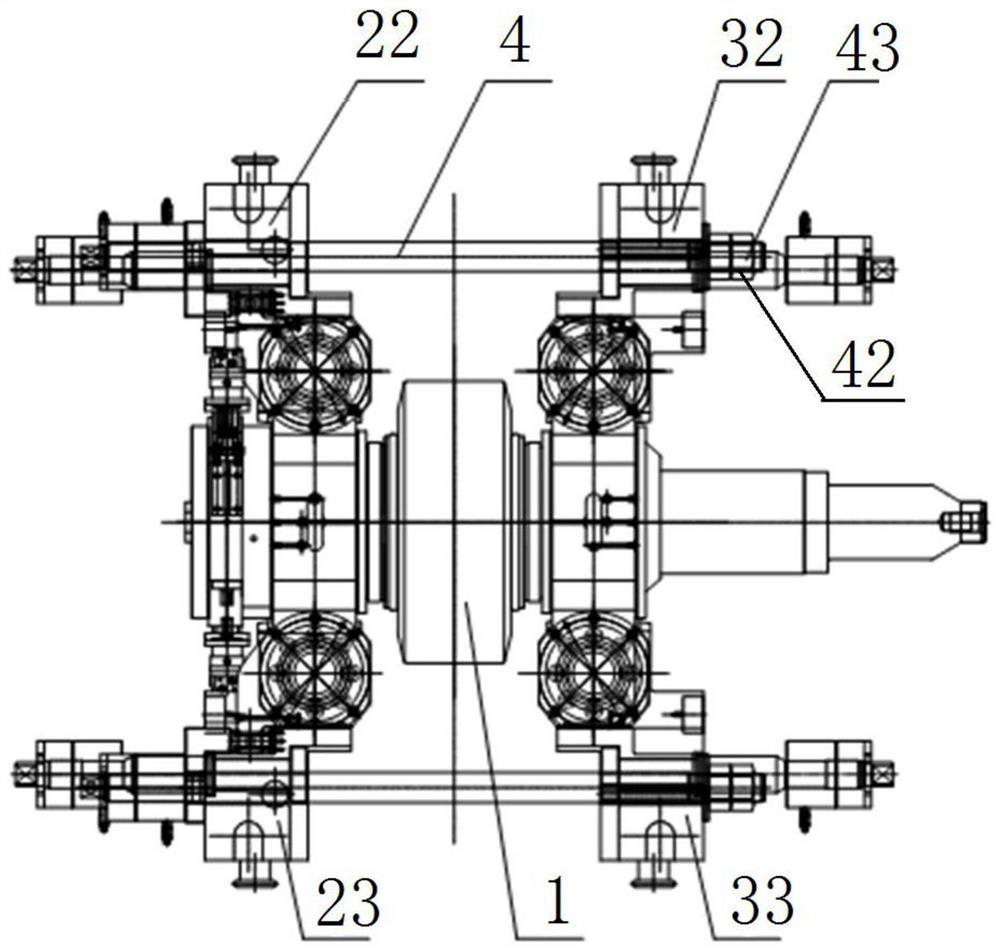

[0045] Embodiment 1: One end of the guide beam 4 has a threaded part 42 at one end, and the other end has a limiting part 41 (similar to a large bolt structure), and the outer diameter of the limiting part 41 is greater than the outer diameter of the pull rod in the middle of the guide beam 4 , while the outer diameter of the limiting portion 41 is greater than the inner diameter of the first through hole 21, to ensure that the guide beam 4 passes through the first through hole 21, the limiting portion 41 can fit the first through hole 21 The outer wall realizes the function of limiting, and then the middle part of the guide beam 4 passes through the fourth conduction hole of the guide device 5 in turn, and then passes through the second conduction hole 31 on the transmission side, and then passes through the second conduction hole 31 on the second guide beam. The through hole 31 is away from the opening on the side of the first through hole 21, and the guide beam 4 is tightene...

Embodiment 2

[0046] Embodiment 2: Both ends of the guide beam 4 are threaded parts 42, and the connection method of the threaded part 42 on the transmission side is the same as that of Embodiment 1, the difference is that the limiting part 41 in the original embodiment 1 is provided with hydraulic pressure Lock nut 8, hydraulic lock nut 8 adopts prior art and gets final product, by connecting the threaded portion 42 at one end of guide beam 4 with the inner thread in the inner cavity 83 of hydraulic lock nut 8, realize the fixing of the two, Simultaneously, the internal thread of inner cavity 83 is on the first piston rod 82 of hydraulic locking nut 8, as Figure 8As shown, the specific implementation process is as follows. First, the first piston rod 82 is driven to move to the right, and then the threaded part 42 at the right end of the guide beam 4 is screwed onto the nut 43. The side bracket 3 is fixed, but it is not strong enough. At this time, the first piston rod 82 is driven to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com