Multifunctional plane rotary vibrating screen for raw material processing

A multi-functional, vibrating screen technology, which is applied in the direction of filtering, solid separation, loading/unloading, etc., can solve the problems of easy aggregation of materials, lack of temporary storage function of materials, and inconvenient transportation of finished products, so as to avoid waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

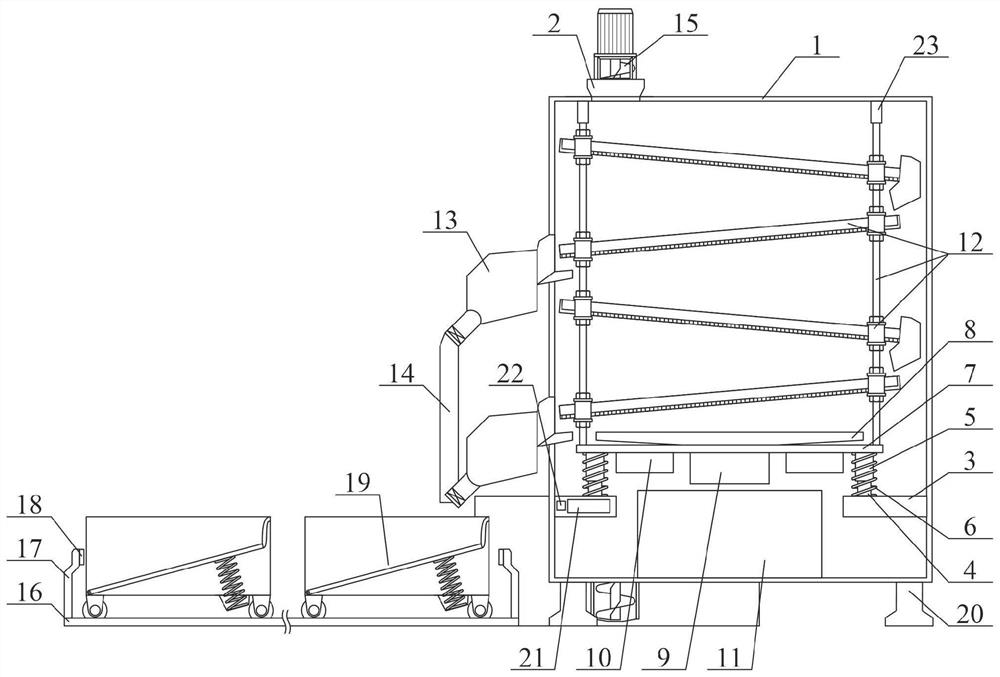

[0041] as attached figure 1 And attached figure 2 shown

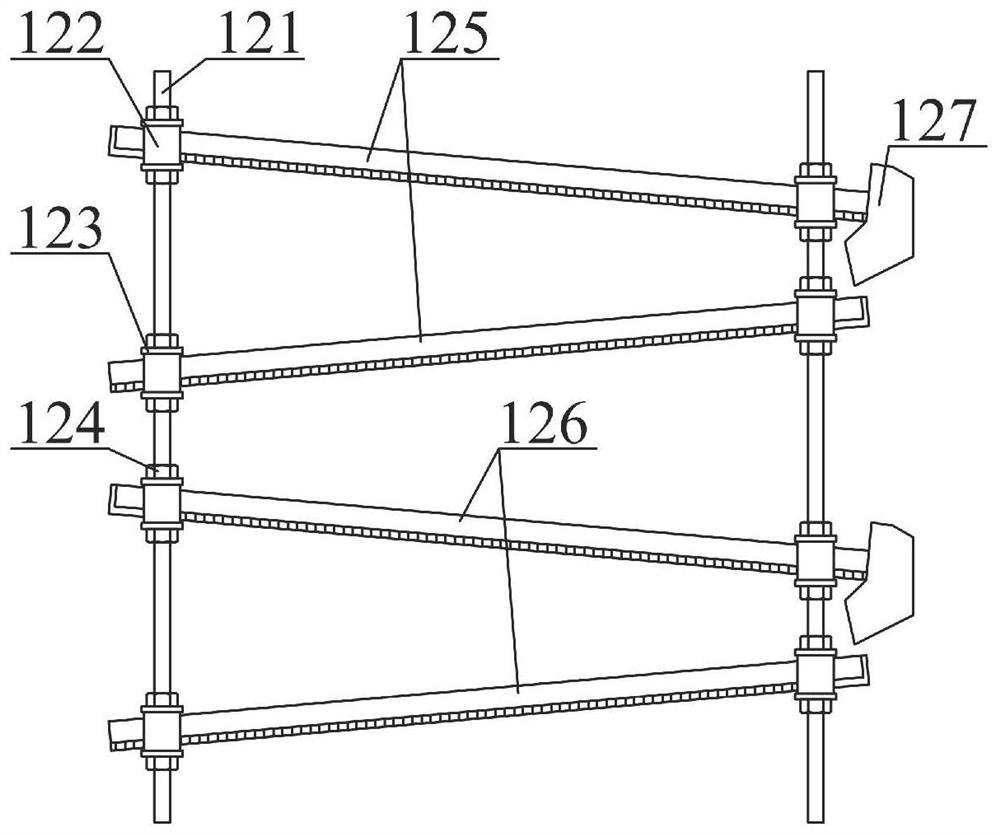

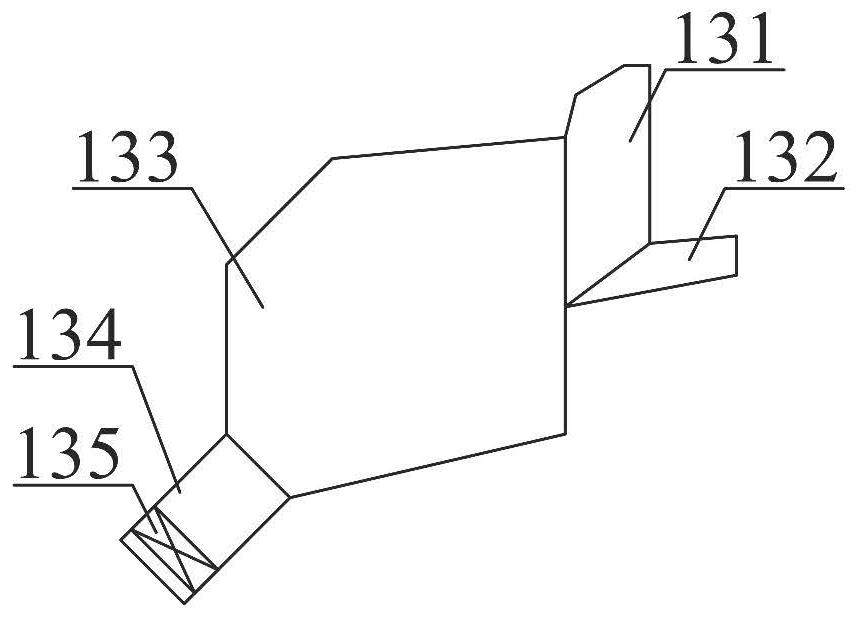

[0042] The present invention provides a multifunctional planar rotary vibrating screen for raw material processing, which includes a fixed outer frame 1, a hopper 2, a horizontal fixed plate 3, a positioning rod 4, a positioning tube 5, a buffer spring 6, a transverse connecting plate 7, and a dust hopper 8. Dust discharge pipe 9, vibration motor 10, dust collection frame 11, adjustable vibration frame structure 12, temporary storage and export frame structure 13, rear side conduit 14, raw material conveying frame structure 15, horizontal rail 16, longitudinal limit frame 17 , a proximity sensor 18, an intelligent conveyor frame structure 19, a fixed leg 20, a controller 21, a power switch 22 and a top pipe 23, and the hopper 2 is plugged into the upper left side of the fixed outer frame 1; The fixed plate 3 is welded on the left and right sides of the lower part of the inner wall of the fixed outer frame 1; the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com