Novel automobile air spring

A technology for air springs and automobiles, applied in elastic suspensions, vehicle components, suspensions, etc., can solve problems such as excessive dust accumulation at pistons, poor overall resistance of air springs, and lack of dustproof functions, etc., to achieve enhanced Shock-absorbing cushioning effect, enhancing resistance effect, effect of stabilizing shock-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

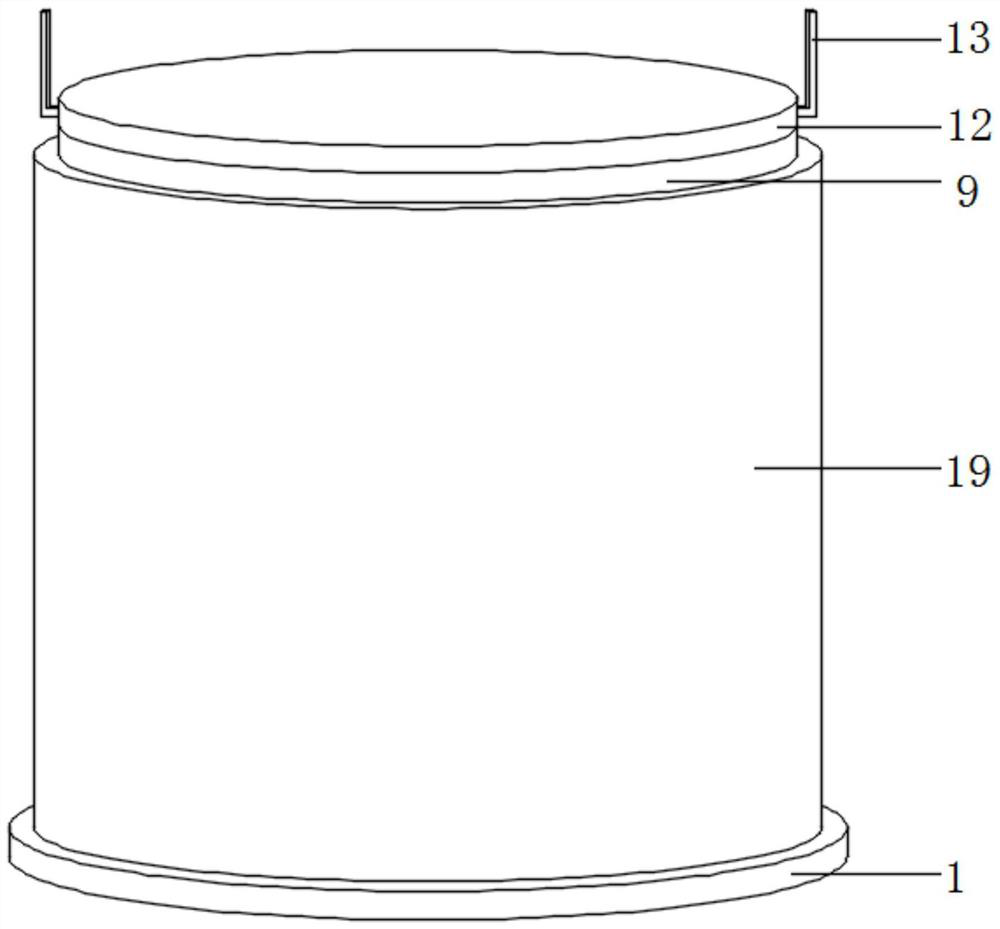

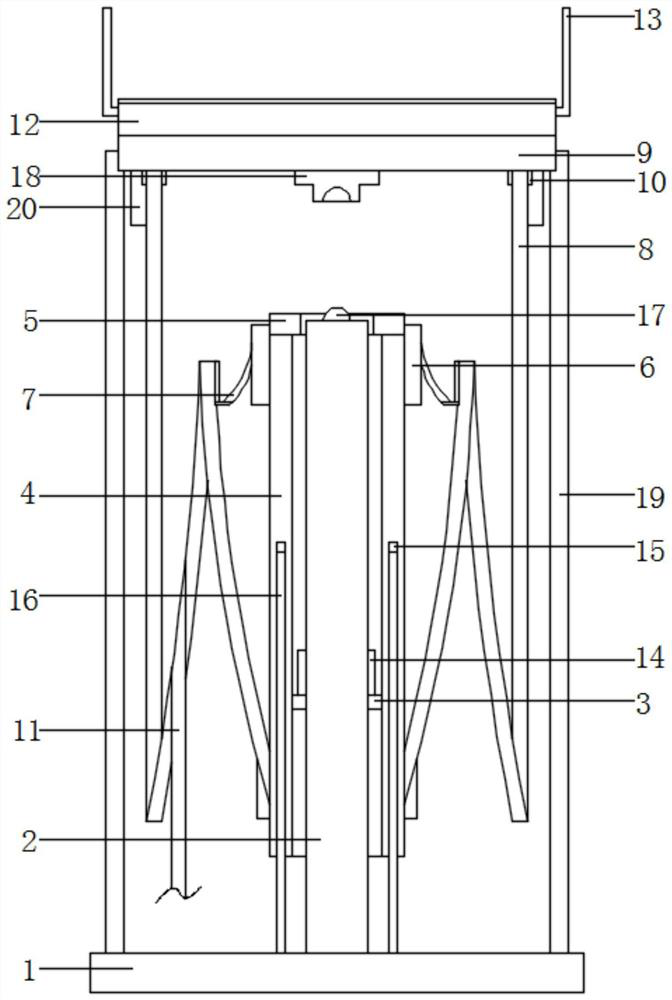

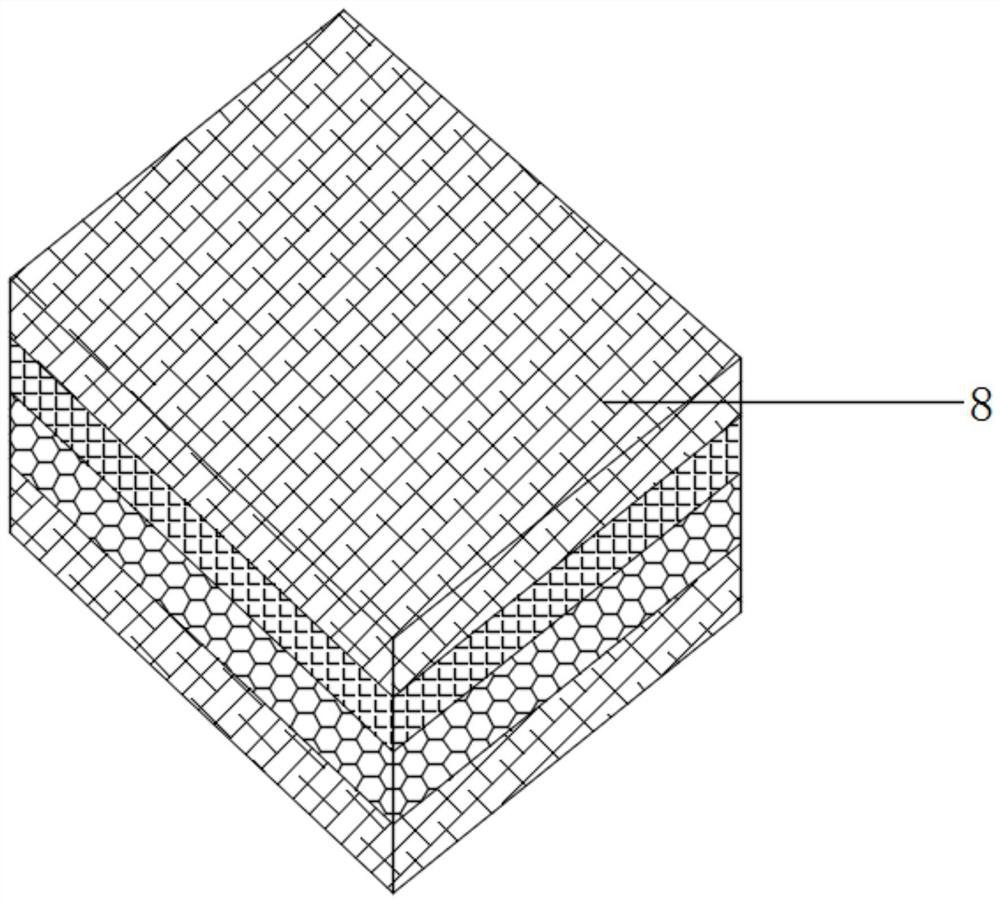

[0020] Example 1, see the embodiment Figure 1 to 3 The present invention provides a technical solution: a new automobile air spring, comprising a lower plate 1, the lower end of the bottom plate 1 is fixed to the slider 2 is connected to the piston, wherein the portion near the surface of the second piston fixedly connected to the slider a sealing ring 3, the sliding surface of the seal ring 3 is connected to a piston sleeve 4, the sleeve 4 is fixed to the top of the piston ring is connected to the cover 5, near its top surface 4 of the piston sleeve 6 is fixedly connected with a fixing plate, the fixing plate 6 side fixedly connected elastic plate 7, the surface of the elastic plate 7 is fixedly connected with an air spring housing 8, the air spring sleeve top 8 is placed an upper end plate 9, the bottom end plate 9 is fixedly connected with a seal fixed block 20, a seal fixing block 20 the surface of the fixed ring 10 is connected to the tensioner, the tensioner ring 10 is sleev...

Embodiment 2

[0025] Example 2, see Figure 1 to 3 The difference between the embodiment 1, the present embodiment is in that embodiment: a top plate 9 is fixed to the upper end of cleat 12 is connected to the upper surface of the cleat 12 is coated with a heat-resistant coating filled, 12 can be increased to some extent on the end plate 9 secure cleat Spend. The hindered side plate 13 of cleat 12 is fixedly mounted, the number of blocking plate 13 is two bits, and the number of bits for the two barrier plate 13 is evenly distributed over the cleat 12 to reduce vehicle motion caused during the air spring biased shifting situation. Top of the piston is fixedly connected to the slider 2 has an elastic bump 17, the lower surface of the upper plate 9 is fixedly connected with a resilient recessed plate 18, and the elastic plate 18 is positioned directly above concave resilient bump 17 by the elastic projections 17 and the elastic recess plate 18 is provided to enhance the cushioning effect of the da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com