Automatic adjusting type opening expanding device for woven bag production

An automatic adjustment, woven bag technology, applied in the direction of solid materials, packaging, packaging item types, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

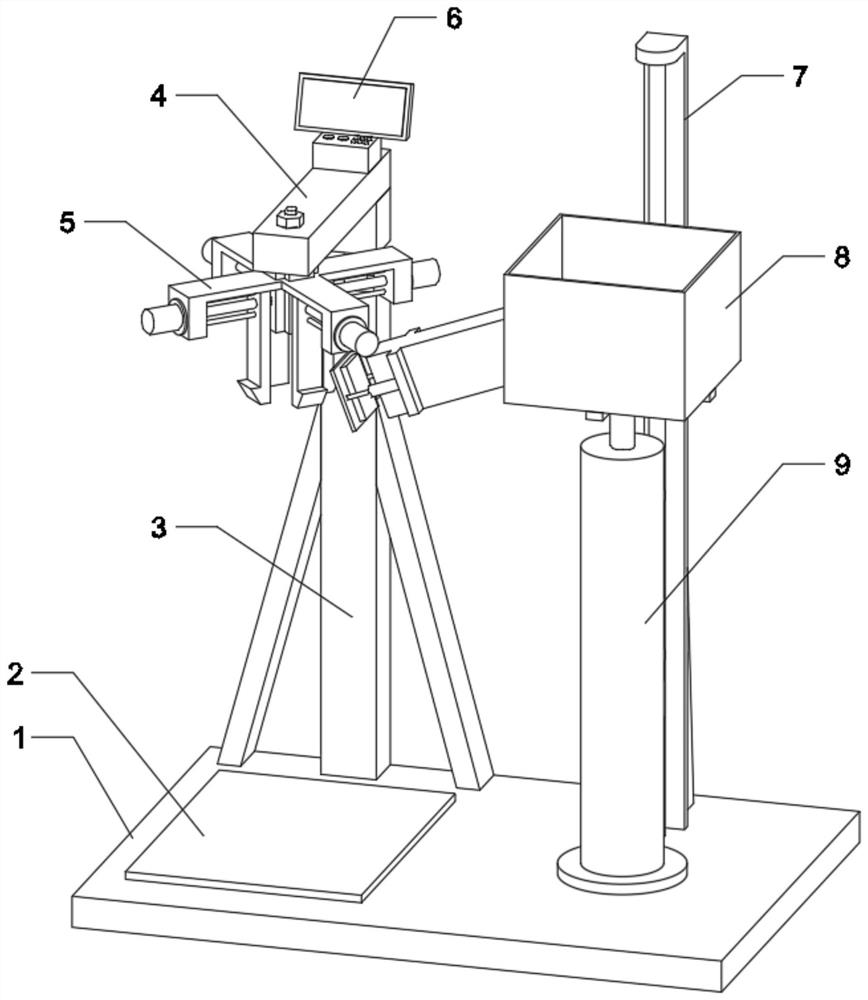

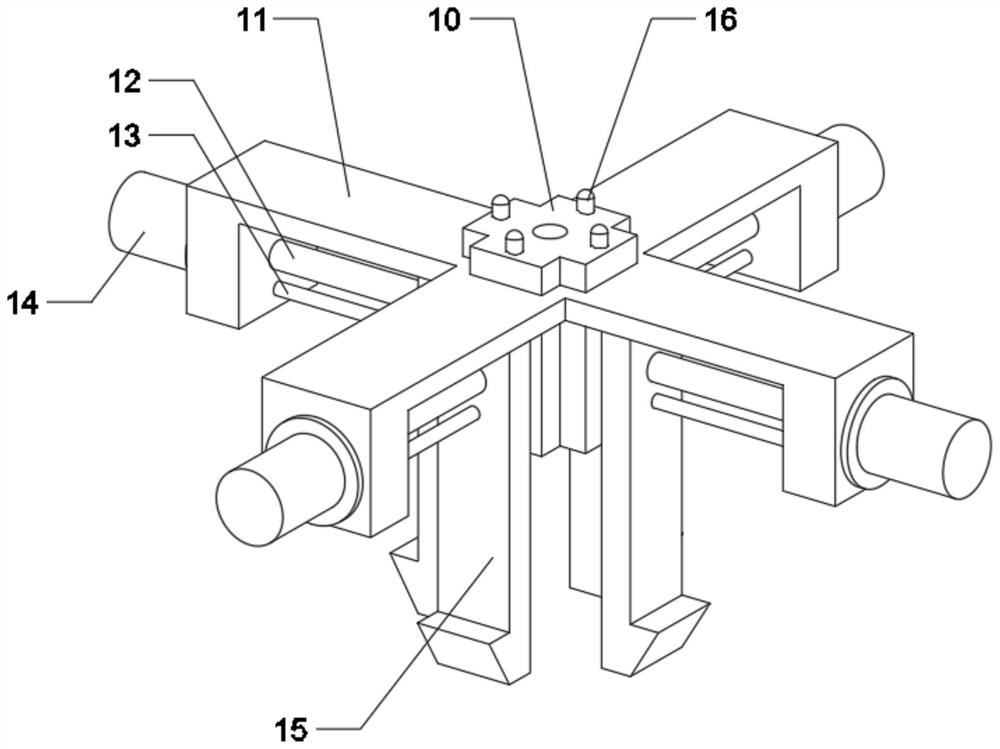

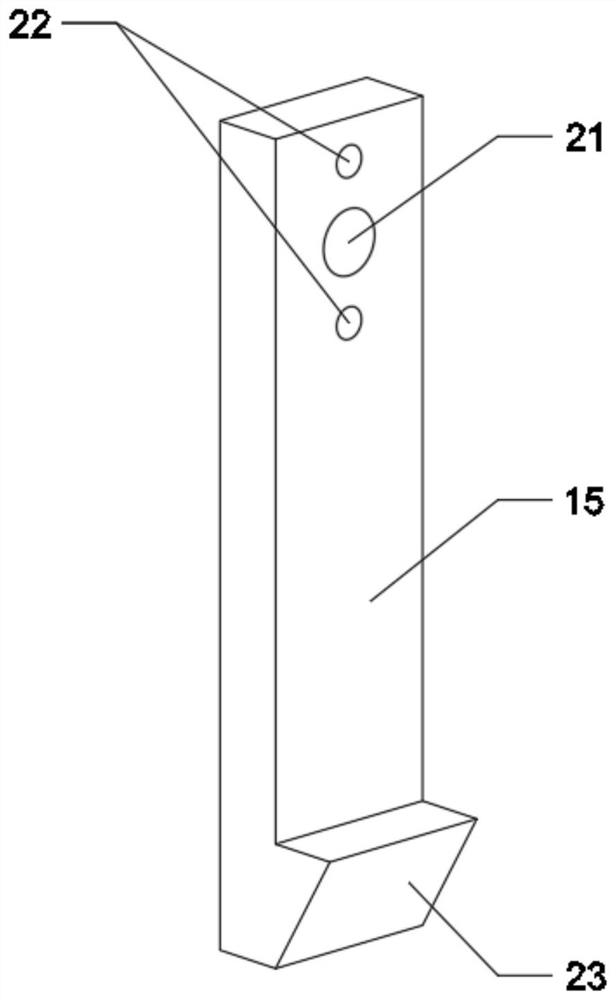

[0024] Example 1, see Figure 1-4 , the present invention provides a technical solution: an automatic adjustable mouth support for woven bag production, including a base 1 and a controller 6, one end of the top side of the base 1 is vertically fixed with a first electric lifting column 3, the second The top of an electric lifting column 3 is fixedly provided with a stretching mechanism mounting frame 4, and the lower part of an end far away from the first electric lifting column 3 is fixedly provided with a stretching mechanism 5 on the stretching mechanism mounting frame 4, and the top of the stretching mechanism mounting frame 4 Controller 6 is fixed, and stretching mechanism 5 is made up of mounting post 10, mounting frame 11, leading screw 12, driving motor 14, positioning polished rod 13 and stretching plate 15, and mounting frame 11 is set to four and takes mounting post 10 as The axis is distributed in a cross shape, and the mounting frame 11 is fixed on the mounting co...

Embodiment 2

[0027] Example 2, see Figure 5-6 , the present invention provides a technical solution, an automatic adjustable mouth support for woven bag production. Compared with Embodiment 1, the difference is that: the other side of the top of the base 1 is provided with a lifting hopper, which can The lifting hopper is composed of a second electric lifting column 9 and a hopper 8, the hopper 8 is fixed on the top of the second electric lifting column 9, the hopper 8 is composed of a bucket body 17 and a discharge pipe 18, and the discharge pipe 18 is fixed on On the bucket body 17, an electronic scale 2 is fixedly installed on one side of the top of the base 1, an electric push rod 19 is fixedly fixed on both sides of the outlet of the discharge pipe 18, and a baffle 20 is arranged at the outlet of the discharge pipe 18, and the electric push rod The flexible end of 19 is fixedly connected with baffle plate 20.

[0028] Further, preferably, the bottom of the hopper 8 is fixedly provid...

Embodiment 3

[0030] Example 3, see Figure 7 , the present invention provides a technical solution, an automatic adjustable mouth support for the production of woven bags. Compared with Embodiment 2, the difference is that: one side of the lifting hopper is provided with a hopper stabilization mechanism 7, The hopper stabilization mechanism 7 is made up of a positioning plate 26, a slide bar 27 and a slide bar mounting frame 28. The slide bar mounting frame 28 is vertically fixed on the base 1, and the slide bar 27 is vertically fixed on the base 1 and fixed with the slide bar mounting frame 28. Connected, the positioning plate 26 is fixed on the side of the hopper 8, and the positioning plate 26 is sleeved on the slide bar 27.

[0031]Working principle: The design of the hopper stabilization mechanism 7 is to stabilize the lifting of the liftable hopper. When the hopper 8 moves up and down, the positioning plate 26 fixedly connected with the hopper 8 will move up and down along the slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com