An oil-free screw compressor

A compressor and oil screw technology, which is applied in the field of oil-free screw compressors, can solve the problems of noise leakage, noise leakage to the outside, noise increase, etc., and achieve the effect of sufficient cooling and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

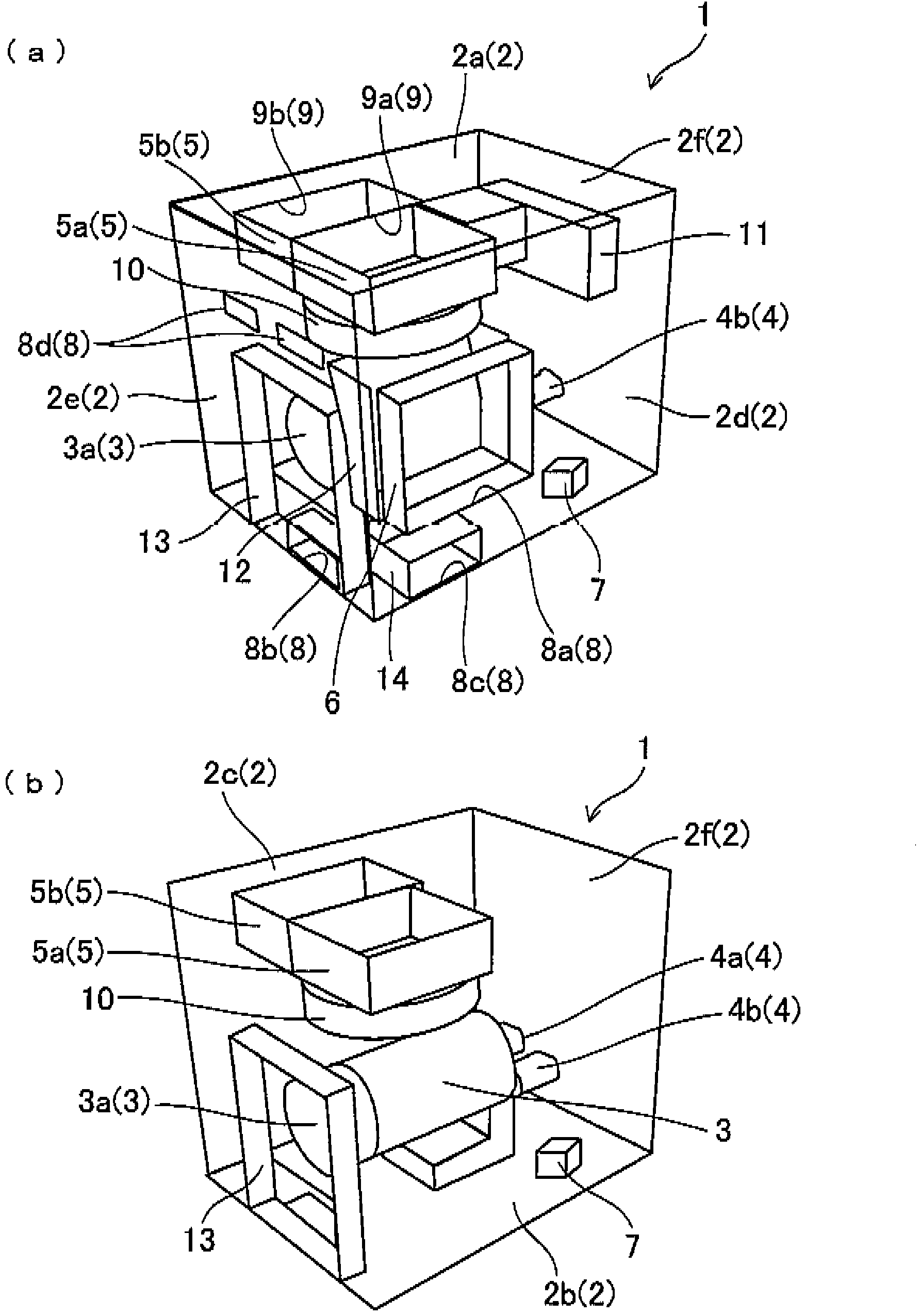

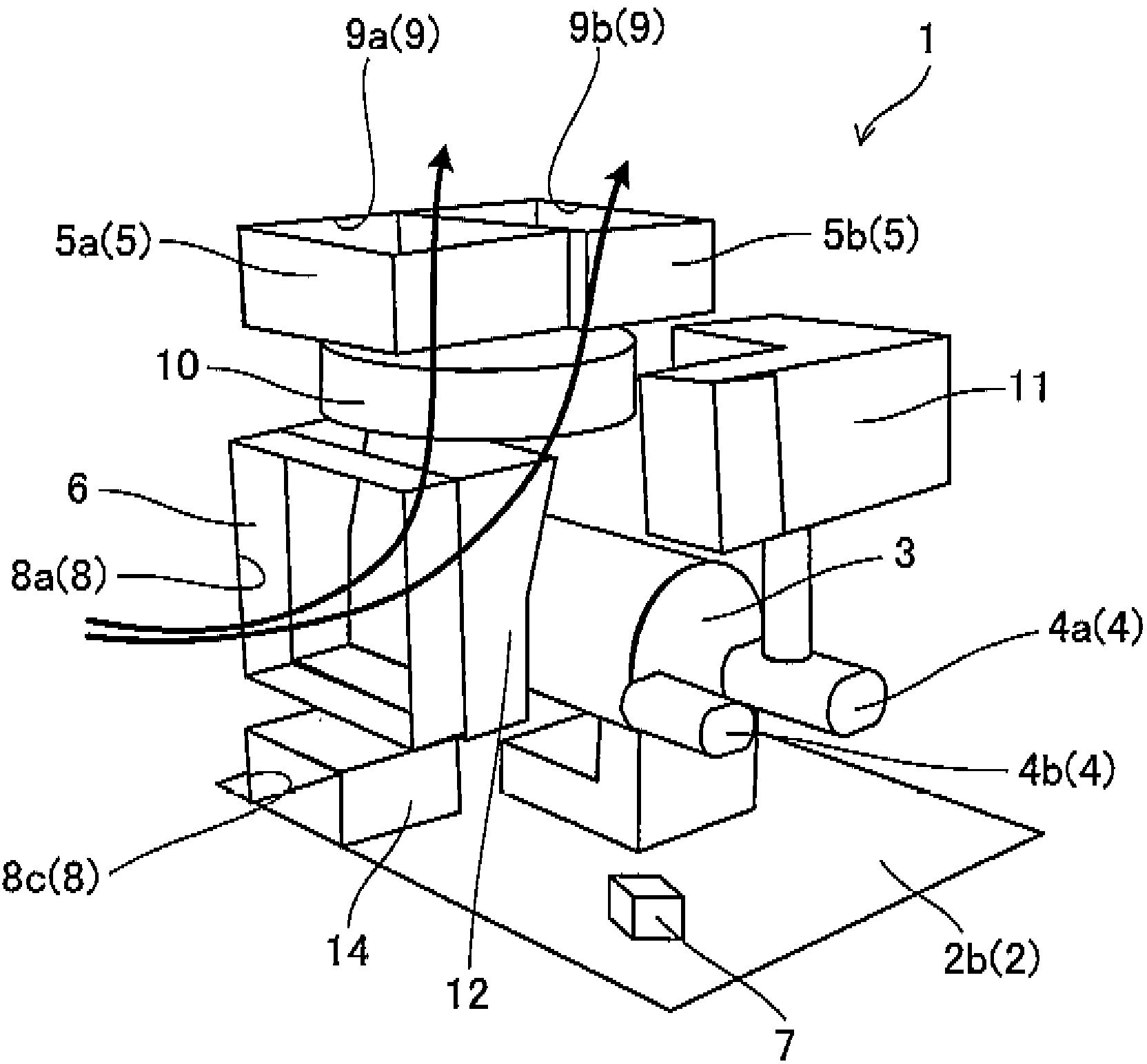

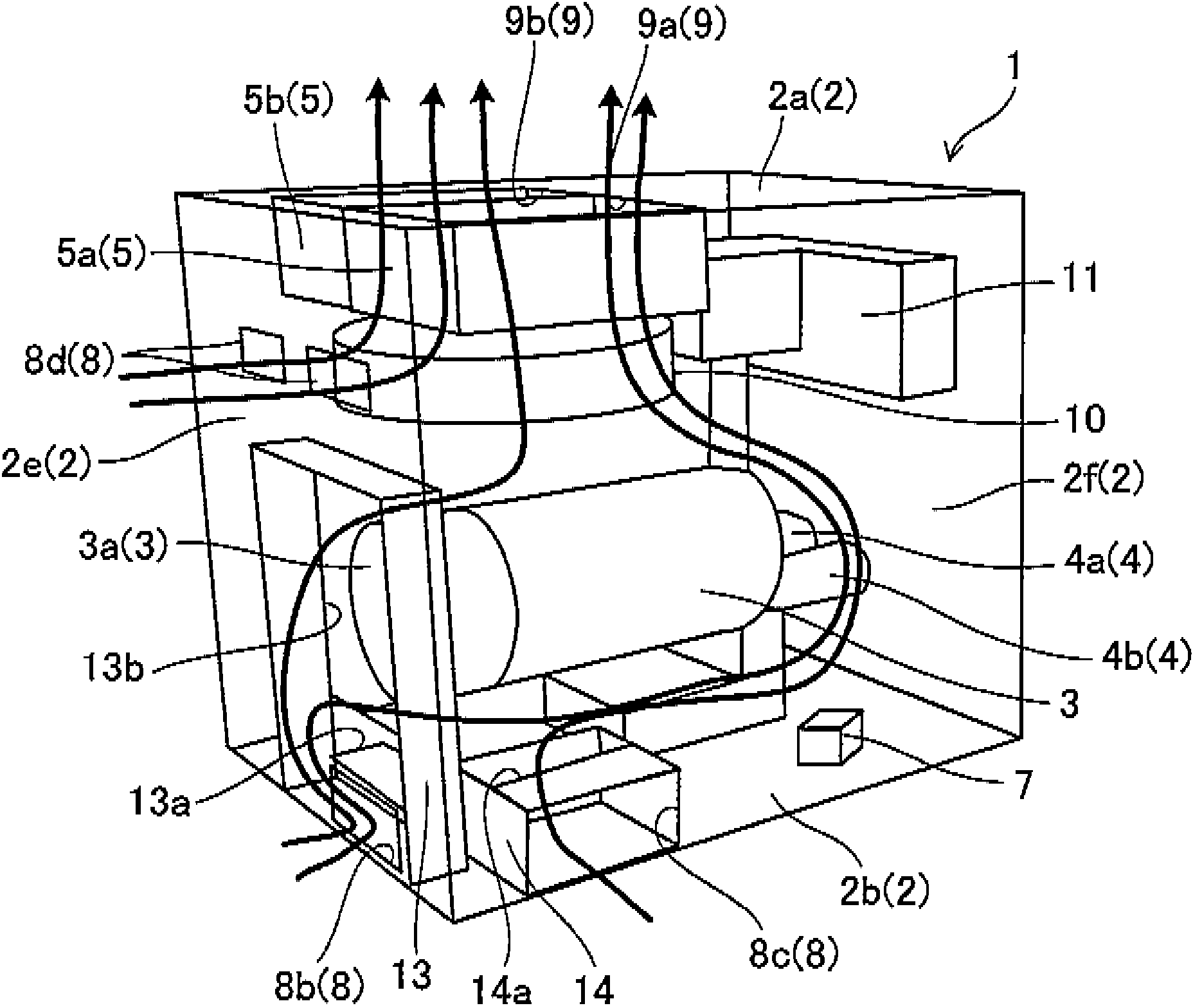

[0065] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

[0066] (Structure of oil-free screw compressor)

[0067] The oil-free screw compressor 1 of this embodiment cools the air compressed by the compressor main body 4 driven by the electric motor 3 with the gas cooler 5, and cools the lubricating oil used in the drive system of the compressor main body 4 with oil. device 6 for cooling, such as figure 1 As shown, there is a hexahedral housing 2 with built-in electric motor 3 , compressor body 4 , gas cooler 5 and oil cooler 6 . In addition, in figure 1 In (b), the upper surface 2a, the right side 2e, the back surface 2d of the casing 2, the oil cooler 6, the suction duct 11 described later, the suction port communicating with the suction duct 11, and the oil cooler are omitted. The diagram of the opening-side duct 12 for equipment and the opening-side duct 14 for internal equipment.

[0068] The electric motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com