Measuring tool for measuring turnout tie nail pitch of turnout in use state

A nail hole and measuring tool technology, applied in the field of measurement, can solve the problems of large errors, difficult direct measurement, and difficulty in determining the center of two nail holes, etc., to speed up the measurement speed, reduce the overall length, and reduce the effect of measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

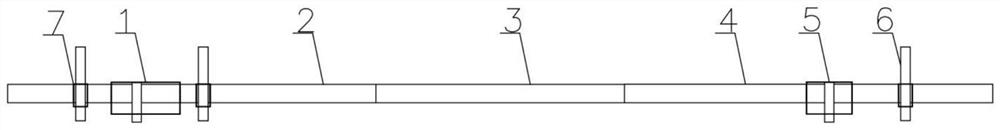

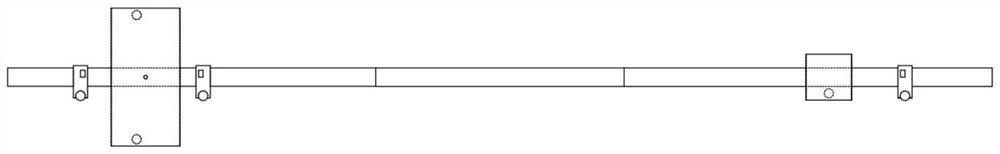

[0029] Such as figure 1 , 2 As shown in , 6, the measuring tool for measuring the distance between the nail holes of the turnout for the turnout in use includes: two rail positioning parts, a group of telescopic rods, three nail hole positioning parts 7 and four nail hole auxiliary positioning parts 8 .

[0030] The rail locating member includes a first rail locating member 1 and a second rail locating member 5, which have a through hole extending horizontally, and a downwardly protruding positioning post is provided on its bottom surface;

[0031] The surface of the telescopic rod has a size scale for marking the distance, and one end of it passes through the through hole of the first rail locator 1 and is locked by a stopper; the other end of the telescopic rod passes through the through hole of the second rail locator 5 , ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap