A vertical prestressed assembled energy-dissipating joint wall structure and its assembly method

A technology of vertical prestressed and jointed walls, applied in the direction of structural elements, truss structures, walls, etc., can solve the problems that the construction quality is difficult to guarantee the post-earthquake structure, the residual deformation of the damaged structure, and the high repair cost, and achieve enhanced deformation and Power consumption, good self-reset, simple and quick repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

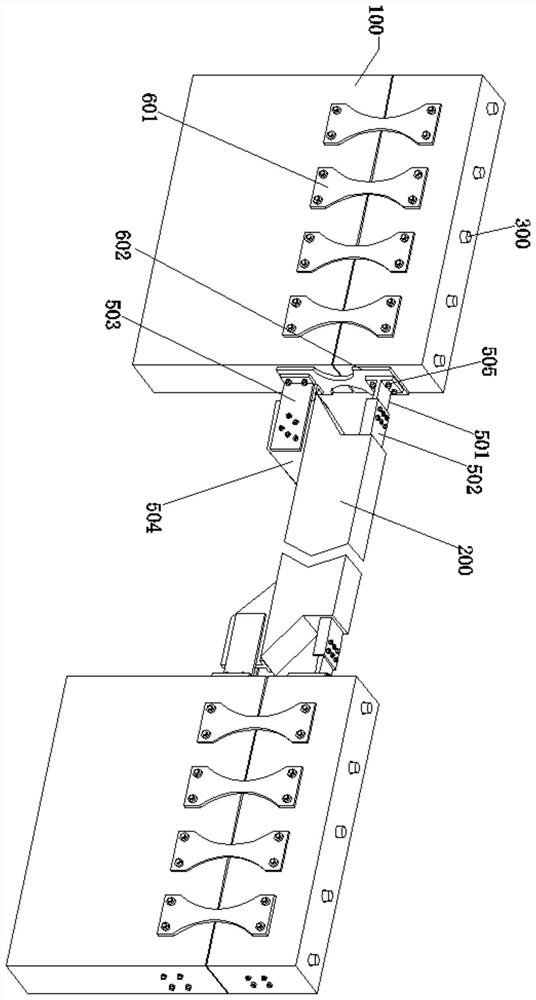

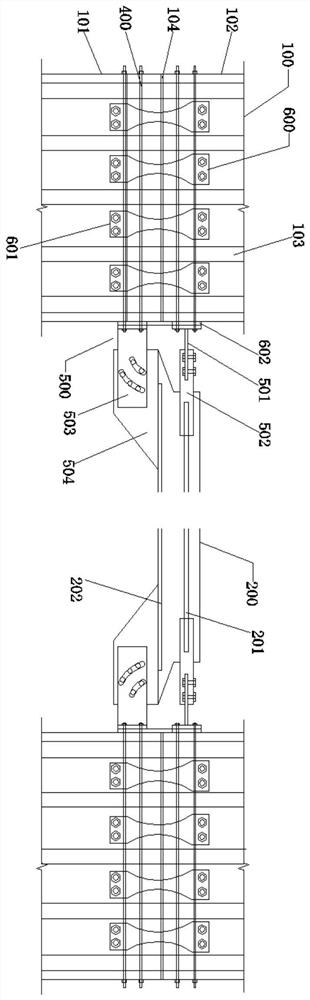

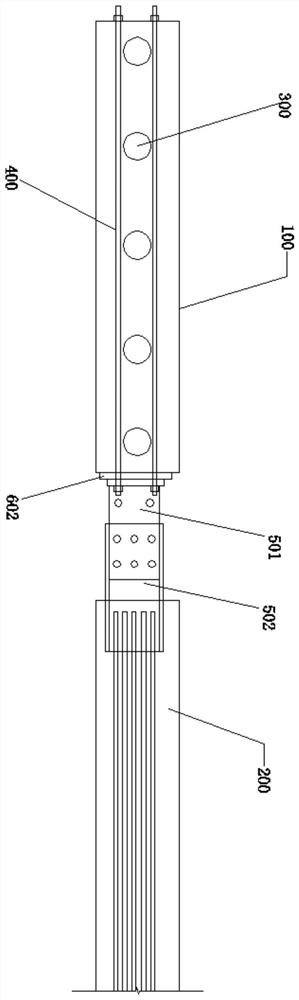

[0053] This embodiment 1 proposes a vertical prestressed assembled energy-dissipating combined limb wall structure, the main structure of which mainly includes vertical segmental prefabricated wall limb assemblies 100, reinforced concrete connecting beams 200, vertical unbonded prestressed tendons 300 , prestressed steel rod 400 , energy-dissipating connection joint assembly 500 at the end of the connecting beam, and energy-dissipating connection joint 600 at the vertical wall pier.

[0054] When setting, the top and bottom elevations of the vertical section prefabricated wall pier assembly 100 are respectively located at the floor elevation. Among them, the vertical section prefabricated wall pier assembly 100 includes the bottom vertical section prefabricated wall pier 101 and several adjoining layer vertical section prefabricated wall pier 102, the bottom vertical section prefabricated wall pier 101 and the adjoining layer vertical section A row of vertical prestressed tend...

Embodiment 2

[0066] Embodiment 2 discloses a method for assembling a vertically prestressed energy-dissipating joint wall structure, including the following steps:

[0067] Step 1: The prefabricated wall plinth 101 of the foundation and the vertical section of the bottom layer is cast-in-place;

[0068] Step 2: pre-embed the vertical unbonded prestressed tendons 300 at the bottom of the foundation and pass through the vertical prestressed tendon holes 103 on the prefabricated wall pier 101 of the bottom vertical section;

[0069] Step 3: Lay ultra-high-performance concrete mortar cushion 104 on the upper part of the prefabricated wall plinth 101 of the vertical section of the bottom layer, and then place the prefabricated wall pier 102 of the vertical section of the adjoining layer in place, and vertically unbonded prestressed tendons 300 Pass through the vertical prestressing tendon hole 103 reserved on the prefabricated wall pier 102 of the vertical section of the adjoining layer, and in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com