Stereoscopic multi-dimensional anti-loosening structure with capability of never loosening

An anti-loose, multi-dimensional technology, applied in the direction of connecting components, screws, threaded fasteners, etc., can solve the problems of low occlusal strength, clamping thread slippage, increased cost, etc., to avoid mutual rotation and prevent screw loosening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

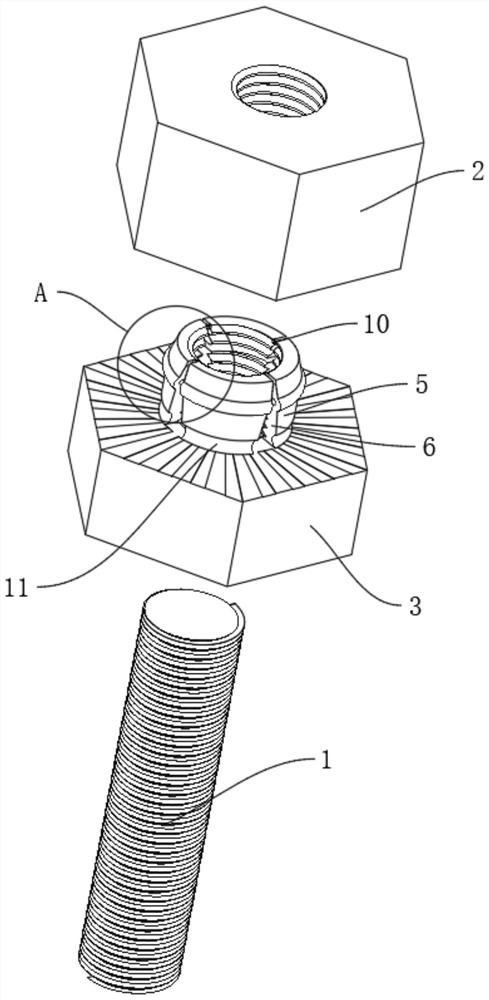

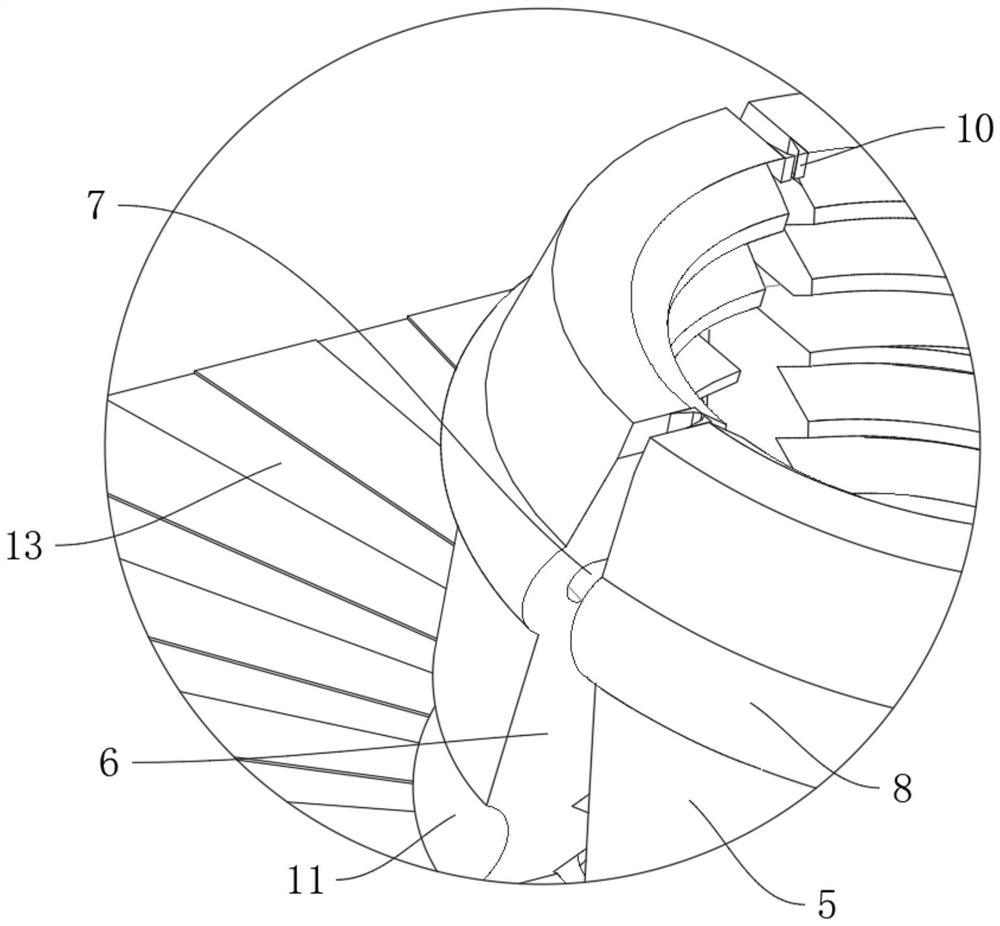

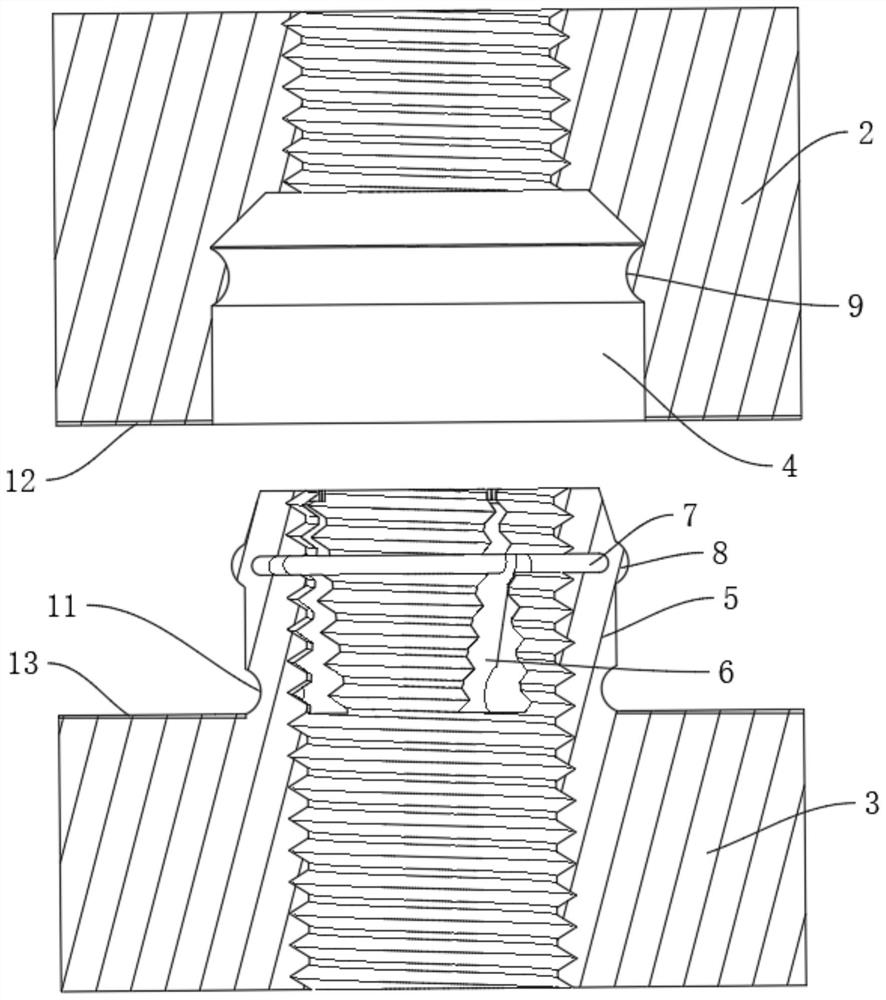

[0025] Such as Figure 1 to Figure 5 As shown, the present invention proposes a three-dimensional multi-dimensional never-loosing anti-loosening structure, comprising a screw 1, on which an upper nut 2 and a lower nut 3 are screwed, and the upper nut 2 faces the lower screw. One end of the cap 3 is provided with a mounting groove 4, and the mounting groove 4 communicates with the inner diameter hole of the upper nut 2; 5. In this embodiment, there are four clamping pieces 5 , and a movable groove 6 is formed between two adjacent clamping pieces 5 , and the inner side of the clamping pieces 5 is threadedly connected with the screw rod 1 .

[0026] When in use, the upper nut 2 abuts against the lower nut 3, and the clamping piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com