Steel plate defect detection method and computer readable storage medium

A defect detection and steel plate technology, applied in the direction of calculation, structured data retrieval, image data processing, etc., can solve problems such as the inability to effectively realize online detection of steel plate defects, and achieve the effect of improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

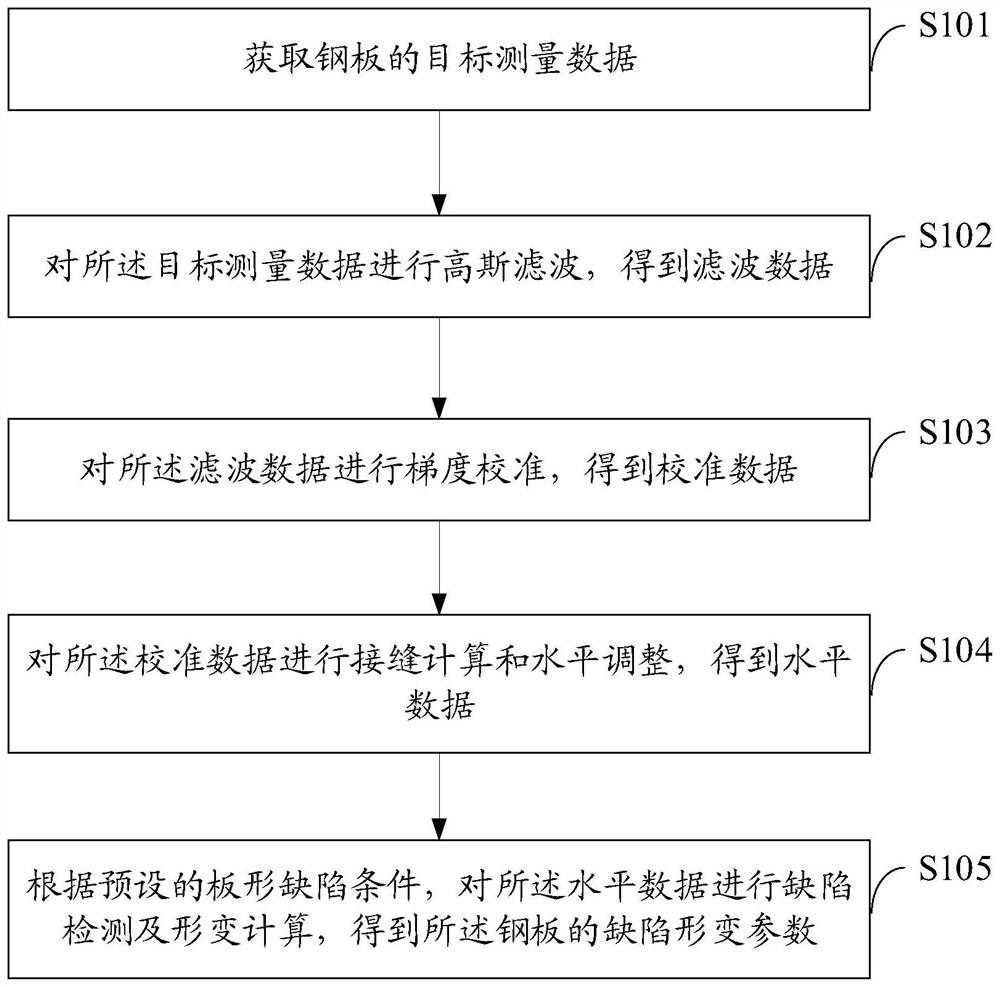

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] During the process of filing this application, the applicant also found that: At present, there are a variety of non-contact plate shape scanning devices based on laser profilometer technology on the market. The algorithms used by these devices have difficulties in calibration, small measurement ranges, and no shock absorption. Measures, no evaluation plan, etc. For example:

[0055] A global calibration method for a multi-line laser profile scanning sensor, based on a three-dimensional target calibration method, which needs to be calibrated with a target in advance before each measurement, and when the target is placed, it must be ensured that the line laser emitted by each sensor intercepts the corresponding It is difficult to be used in production sites with complex working conditions.

[0056]A single-camera plate shape detection system based on line laser is a system for off-line detection of plate shape based on line laser. Scan the process video of the medium a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com