Device for adjusting line sequence

A technology for adjusting lines and driving devices, applied in electrical components and other directions, can solve the problems of low production efficiency and high manual work intensity, and achieve the effect of reducing work intensity, reducing work intensity and avoiding errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

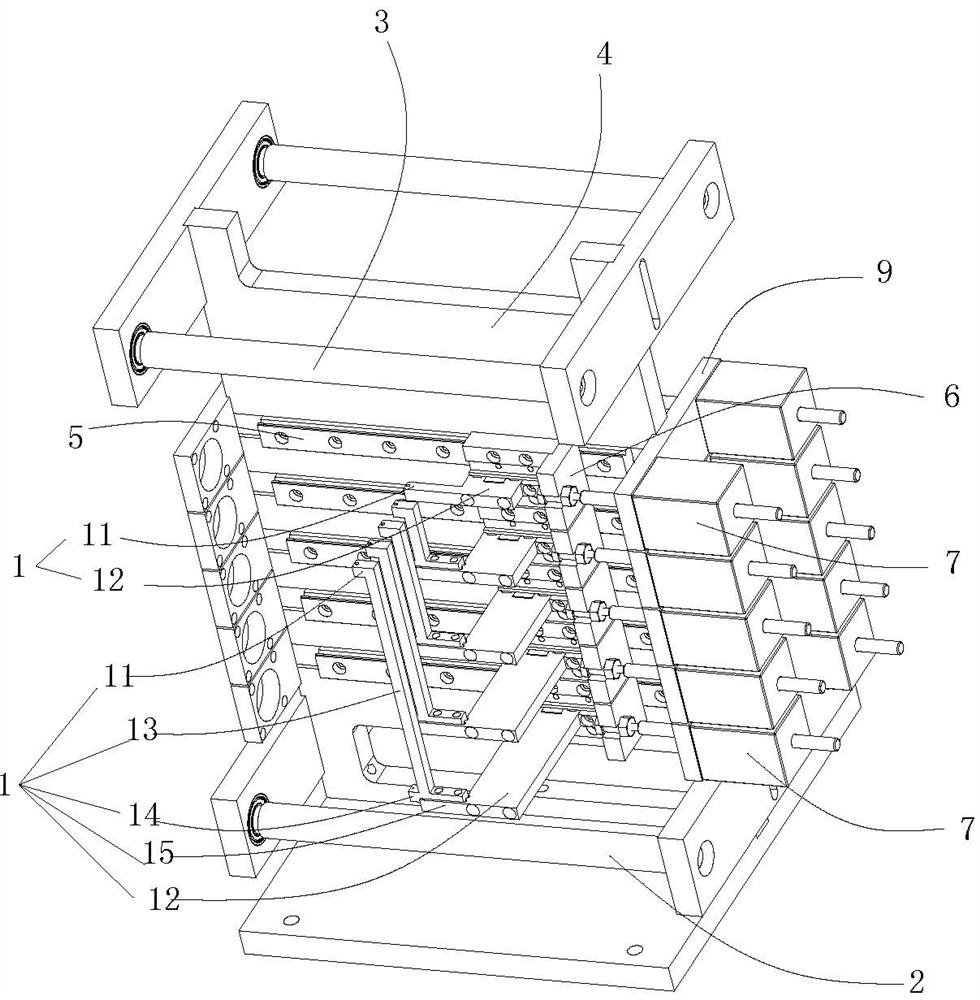

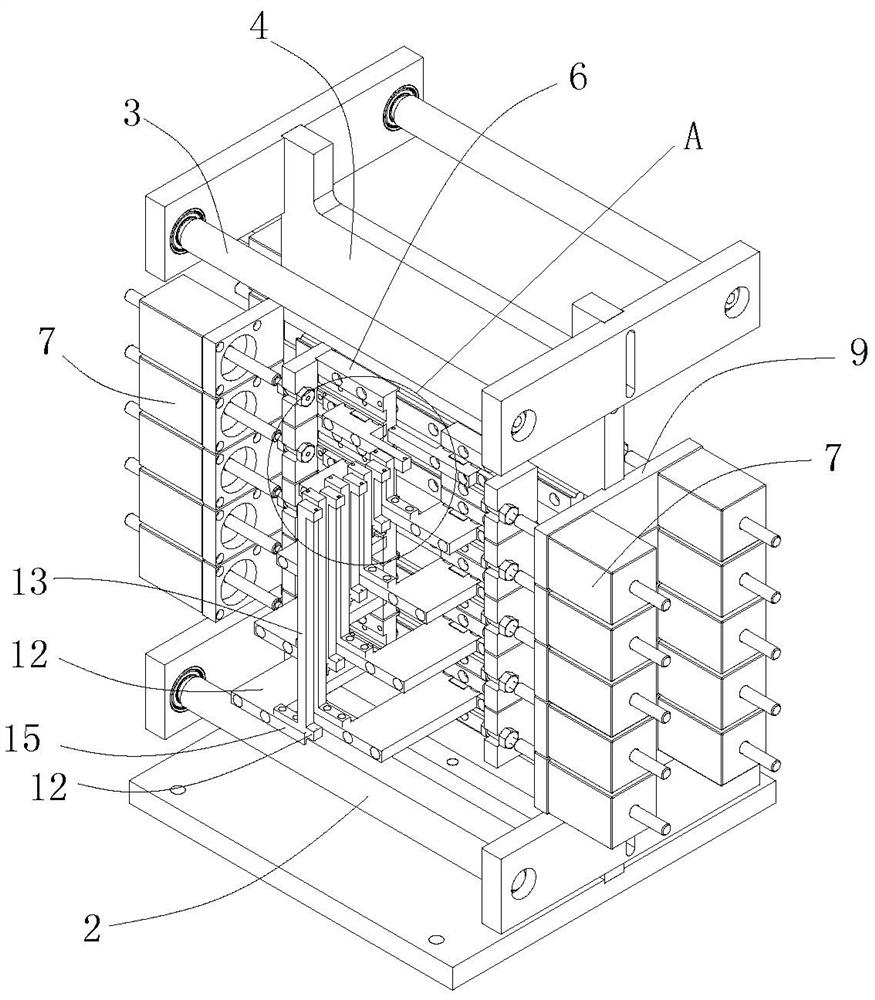

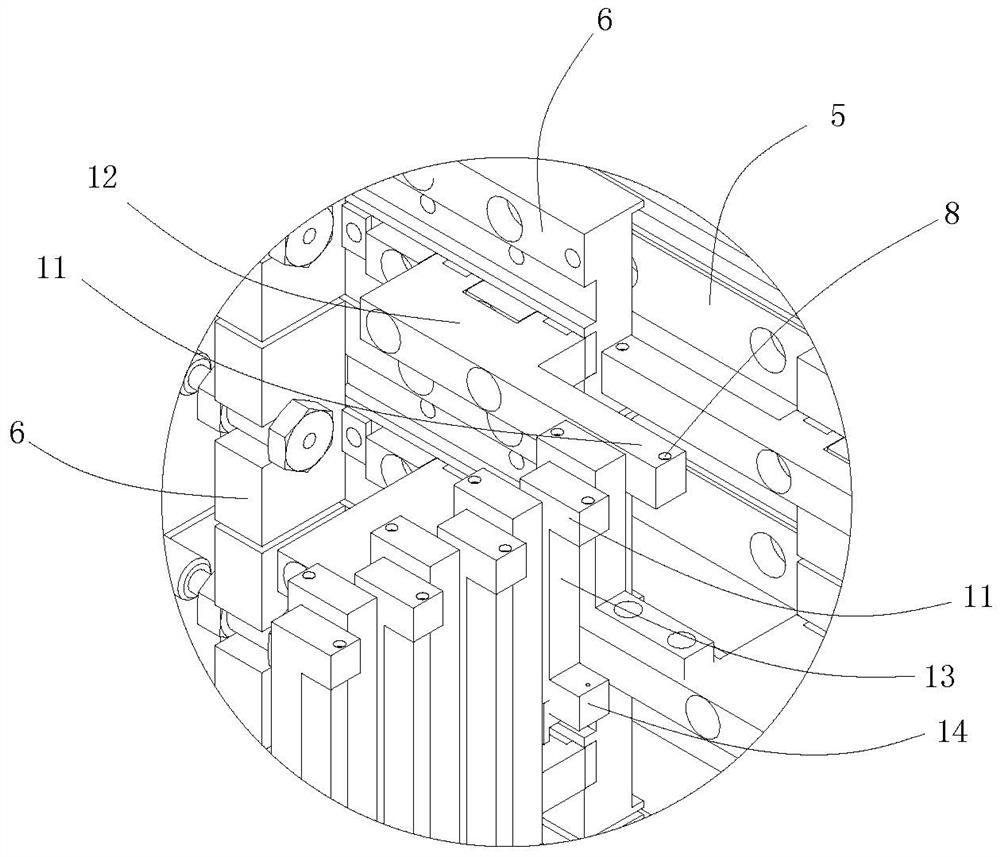

[0023] Example: see figure 1 , figure 2 A device for adjusting the line order, which includes: a plurality of threading structures, the threading structure includes a threading block 1, the threading block 1 is provided with a threading hole 8 arranged vertically, and the threading holes of the threading block 1 8 are arranged at intervals in the longitudinal direction; wherein at least two threading blocks 1 are respectively connected with a lateral movement mechanism; it also includes an upper guide column 3 arranged laterally; it is located above the threading structure.

[0024] When this technical solution is implemented, the threading block 1 is moved according to the order of the wires on the wire harness, so that all the threading holes 8 are arranged at intervals in the lateral direction; The guide column 3 is drawn out horizontally, and since the threading holes 8 are arranged at intervals in the lateral direction, the wire rods pass through the upper guide column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com