Lightweight, scratch-resistant and wear-resistant PMMA alloy material and preparation method thereof

An alloy material and scratch-resistant technology, which is applied in the field of PMMA alloy material and its preparation, can solve the problems of reducing surface hardness and scratch resistance, increasing the density of PMMA alloy material itself, so as to improve rigidity and heat resistance, and improve scratch resistance Injury effect, the effect that the specific gravity is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

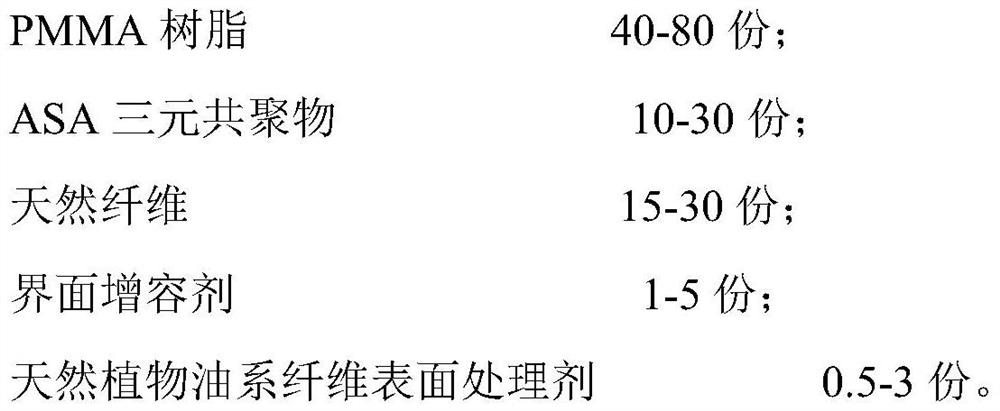

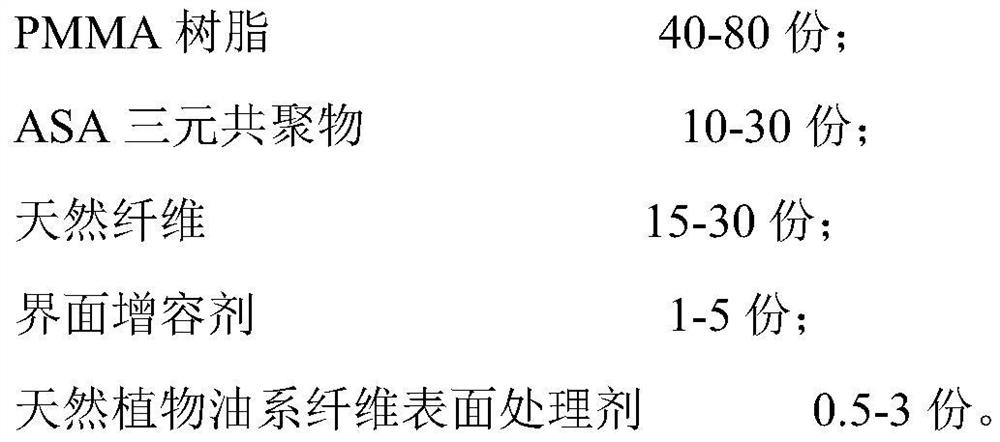

Method used

Image

Examples

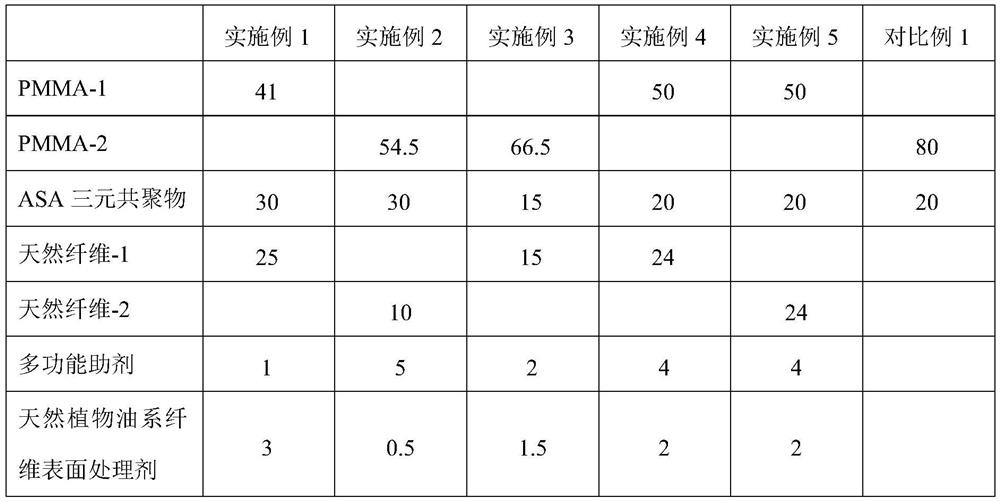

Embodiment 1

[0037] Take by weighing natural fiber, natural vegetable oil fiber surface treatment agent respectively by the embodiment 1 data shown in table 1, natural vegetable oil fiber surface treatment agent is added in the glass container containing 300ml high-concentration ethanol (90%), adjust The temperature of the water bath is 85°C, ultrasonic emulsification and dispersion for 20 minutes; then put the surface treatment agent and natural fiber together into the high-speed mixing mixer, and stir at a high speed of 300 rpm for 10 minutes, so that the surface of the natural fiber can be evenly distributed. cladding.

[0038] Take by weighing PMMA resin, ASA terpolymer, interfacial compatibilizer by the embodiment 1 data shown in table 1, be placed in the main feeding bin of a conical single-screw extruder of high torque after mixing , into the barrel of the extruder through the feeding screw; the surface-treated natural fiber is placed in the side feeding bin of the extruder, and add...

Embodiment 2

[0040] Take by weighing natural fiber, natural vegetable oil fiber surface treatment agent respectively by the embodiment 2 data shown in table 1, natural vegetable oil fiber surface treatment agent is added in the glass container that contains 300ml high-concentration ethanol (90%), adjust The temperature of the water bath is 85°C, ultrasonic emulsification and dispersion for 20 minutes; then put the surface treatment agent and natural fiber together into the high-speed mixing mixer, and stir at a high speed of 300 rpm for 10 minutes, so that the surface of the natural fiber can be evenly distributed. cladding.

[0041] Take by weighing PMMA resin, ASA terpolymer, interfacial compatibilizer by the embodiment 1 data shown in table 1, be placed in the main feeding bin of a conical single-screw extruder of high torque after mixing , into the barrel of the extruder through the feeding screw; the surface-treated natural fiber is placed in the side feeding bin of the extruder, and ...

Embodiment 3

[0045] Take by weighing natural fiber, natural vegetable oil fiber surface treatment agent respectively by the embodiment 3 data shown in table 1, natural vegetable oil fiber surface treatment agent is added in the glass container containing 300ml high-concentration ethanol (90%), adjust The temperature of the water bath is 85°C, ultrasonic emulsification and dispersion for 20 minutes; then put the surface treatment agent and natural fiber together into the high-speed mixing mixer, and stir at a high speed of 300 rpm for 10 minutes, so that the surface of the natural fiber can be evenly distributed. cladding.

[0046] Take by weighing PMMA resin, ASA terpolymer, interfacial compatibilizer by the embodiment 1 data shown in table 1, be placed in the main feeding bin of a conical single-screw extruder of high torque after mixing , into the barrel of the extruder through the feeding screw; the surface-treated natural fiber is placed in the side feeding bin of the extruder, and add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com