Quick dismounting type grabbing device

A grabbing device and detachable technology, which is applied in the field of quick-dismantling grabbing devices, can solve the problems of time-consuming disassembly and installation, blockage of the filter layer, and increased time for maintenance personnel to disassemble and install, so as to reduce the number and avoid reverse flow, avoid shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

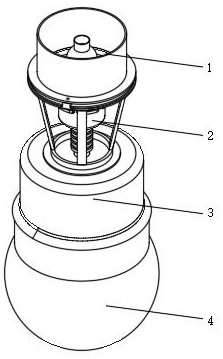

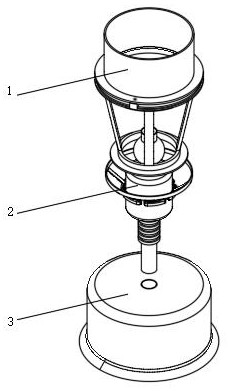

[0035] Such as figure 1 , 2 , 3, 4, 5, 6, 8, and 9, a quick-detachable grabbing device includes a connecting cover 3, a grabbing end 4 and a first inflation tube 5, and the lower end cavity connecting the cover 3 is provided There is a grasping end 4, and a first inflation tube 5 is inserted into the opening at the upper end of the connecting cover 3, and the first inflation tube 5 is connected to the grasping end 4;

[0036] The upper end of the connecting cover 3 is provided with a quick-release connecting flange 1, and the inside of the quick-release connecting flange 1 is provided with a shaking filter device 2;

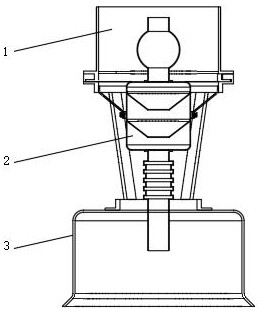

[0037] The quick-release connecting flange 1 includes a first connecting ring 103, an L-shaped insert 104, a second connecting ring 105, a third connecting ring 106 and a ring groove 107, and the upper end of the first connecting ring 103 is provided with two L-shaped inserts. Block 104, the upper end of the first connecting ring 103 is provided with a second c...

Embodiment 2

[0040] Such as Figure 5 , 6As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference is that the quick-release connecting flange 1 also includes a bottom ring 101, a support bar 102 and a fixing cylinder 108, the lower end of the first connecting ring 103 is provided with a support bar 102, and the lower end of the support bar 102 is provided with a bottom ring 101 , the upper end of the third connecting ring 106 is provided with a fixed cylinder 108;

[0041] The bottom ring 101, the support bar 102 and the first connecting ring 103 are set in the shape of a cone, the minimum distance between two adjacent support bars 102 is the same as the diameter of the transparent filter cartridge 203, and one of the L-shaped inserts 104 runs through the secon...

Embodiment 3

[0043] Such as Figure 6 , 7 , 9, wherein the same or corresponding components as those in the first embodiment use the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the differences from the first embodiment will be described below. The difference is that the vibrating filter device 2 also includes a first connecting pipe 206, a connecting hose 207, a ring 208, a square bar 209, an arc cover 210, a spring 211, an arc bar 212 and a rubber pad 213, transparent A first connecting pipe 206 and a connecting hose 207 are provided between the filter cartridge 203 and the first inflation pipeline 5, the upper end of the first connecting pipe 206 is connected with the transparent filter cartridge 203, and the lower end of the first connecting pipe 206 is connected with a connecting hose 207, The inner ring of the first connection ring 103 is provided with a circular ring 208, and the lower end of the circular ring 208 is provided with six s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com