Fabricated wallboard for building main body structure construction

A kind of building main body and prefabricated technology, which is applied in the direction of building components, building structures, buildings, etc., can solve the problems of not being able to improve the stability of wall panels, and achieve the effect of improving the stability of walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

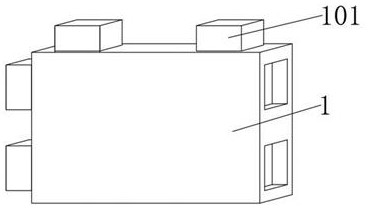

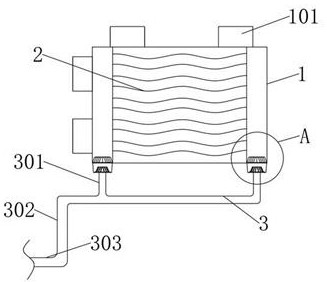

[0028] This embodiment provides a prefabricated wall panel for the construction of the main structure of the building, including a wall 1 and a splicing block 101, the left side and the top of the wall 1 are connected with a splicing block 101, and the bottom of the wall 1 is installed with a drainage device with the function of blocking air. pieces, the wall body 1 is provided with a weight-increasing piece with an expansion function.

[0029] The prefabricated wall panels for the construction of the main building structure provided in this embodiment are assembled with other walls 1 through the splicing blocks 101 on the left side and top of the wall 1. In rainy days, rainwater enters the wall through the gap at the joint of the wall 1 Inside 1, the rainwater is absorbed by the weight-increasing parts, and the weight of the weight-increasing parts increases after absorbing rainwater. At the same time, when it is affected by rainy weather, the internal weight of the wall 1 inc...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that: the right side and the bottom of the wall body 1 in this embodiment are provided with connecting holes matching the splicing blocks 101 .

[0033] Wherein, when the wall body 1 is spliced with another wall body 1 through the splicing block 101, it is convenient to insert the splicing block 101 on the left side and the top into one or more wall bodies 1 and connect the right side with the connecting hole at the bottom, so as to achieve splicing. Purpose.

Embodiment 3

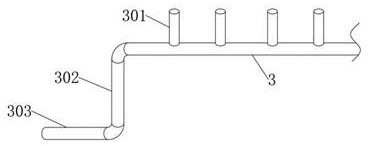

[0035] The difference between this embodiment and Embodiment 1 is that the drainage parts in this embodiment include a suspension pipe 3, a connecting branch pipe 301, a standpipe 302, an outlet pipe 303, an air baffle 304, a clamp ring 305, a chassis 306 and a rain bucket 307 , the outer surface of the suspension pipe 3 is connected with a connecting branch pipe 301, the top of the connecting branch pipe 301 is connected with a rainwater bucket 307, the top of the rainwater bucket 307 is connected with a chassis 306, the top of the chassis 306 is connected with a clamp ring 305, and the top of the clamp ring 305 is connected with an air baffle 304, one end of the suspension pipe 3 is connected with a standpipe 302, and one end of the standpipe 302 away from the suspension pipe 3 is connected with an exit pipe 303; both the air baffle 304 and the clamp ring 305 are made of chrome metal; the material of the chassis 306 is molybdenum-containing Stainless steel; one end of the sus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com