Steel matrix inner side spraying and building wall

A technology of steel and substrate, which is applied to the field of spraying the wall inside the steel substrate, can solve the problems of inconvenience of users of the house, and achieve the effect of improving the stability of the wall and excellent overall performance.

Inactive Publication Date: 2016-07-20

ZHENGZHOU SUNDY BUILDING TECH

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the construction process of civil steel structure houses, most of them use standard section steel to make the steel structure main frame, and then attach the walls, doors, windows, roofs and other house components commonly used in house construction to the frame, among which Most of the walls are assembled light-weight walls. In order to strengthen the strength of steel structure houses, especially when the span is large or there are many floors, it is necessary to install steel structure walls in certain parts, that is, steel substrates. These walls Support the main frame to resist external force to ensure the ability of steel structure houses to resist external force. These walls are mostly made of steel plates, steel pipes, section steel, etc. Due to the need for secondary decoration of civil buildings and the need for aesthetics and comfort in use Industrial buildings have high requirements, and these steel substrates often cannot meet these requirements, causing inconvenience to the users of these houses

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

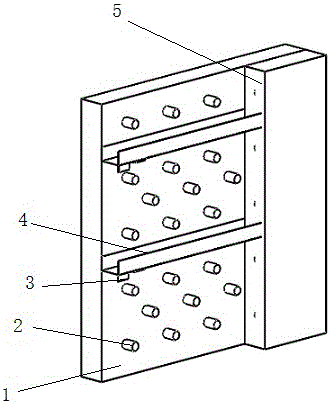

[0009] Embodiment 2, the keel 4 is directly fixedly connected with the steel substrate 1, and the corner code 3 is not used for transition. Others are the same as the embodiment 1, and the implementation of the present invention can also be realized. Its advantage is that it saves materials, and its defect is that the position of the keel is not correct. Good adjustment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a steel matrix inner side spraying and building wall, which belongs to the field of buildings, and comprises a steel matrix, an anchor, a keel and a spraying and building sizing agent, wherein the steel matrix is a steel plate or structural steel or a steel-made cavity internally filled with materials; the anchor is arranged on the surface at one side in the steel matrix; the keel is arranged on the steel matrix and is fixedly connected with the steel matrix; the spraying and building sizing agent is an adhesive light sizing agent formed by gypsum, cement and light particles, and has a fireproof function after being solidified quickly; the spraying and building sizing agent is attached to the inner side of the steel matrix and packages the anchor, a connector and the keel in the sizing agent. The steel matrix inner side spraying and building wall can meet the requirements of civil steel structure buildings on double interior decoration, attractiveness and comfortableness, has the fireproof performance of the steel structure buildings at the same time, and can be tightly combined with the steel matrix, so that the wall stability is improved, and the whole performance is excellent.

Description

technical field [0001] The invention belongs to the field of construction, and in particular relates to a wall sprayed on the inner side of a steel substrate used in steel structure building construction. Background technique [0002] In the construction process of civil steel structure houses, most of them use standard section steel to make the steel structure main frame, and then attach the walls, doors, windows, roofs and other house components commonly used in house construction to the frame, among which Most of the walls are assembled light-weight walls. In order to strengthen the strength of steel structure houses, especially when the span is large or there are many floors, it is necessary to install steel structure walls in certain parts, that is, steel substrates. These walls Support the main frame to resist external force to ensure the ability of steel structure houses to resist external force. These walls are mostly made of steel plates, steel pipes, section stee...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04B2/84

CPCE04B2/84

Inventor 赵嘉珩赵建纲

Owner ZHENGZHOU SUNDY BUILDING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com