Construction method of simple environment-friendly interior wall

A construction method and an environmentally friendly technology, applied to walls, building components, buildings, etc., can solve problems such as occupancy, high structural complexity, and multi-room interior space, and achieve the effects of reducing foaming, ensuring strength, and mixing uniformly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

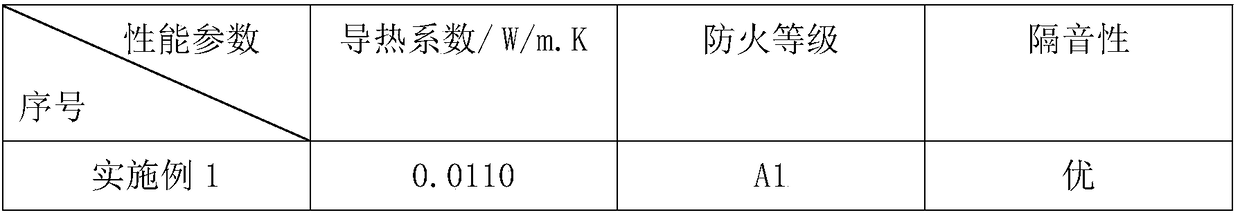

Embodiment 1

[0037] A simple and environment-friendly construction method for an interior wall, comprising the following steps:

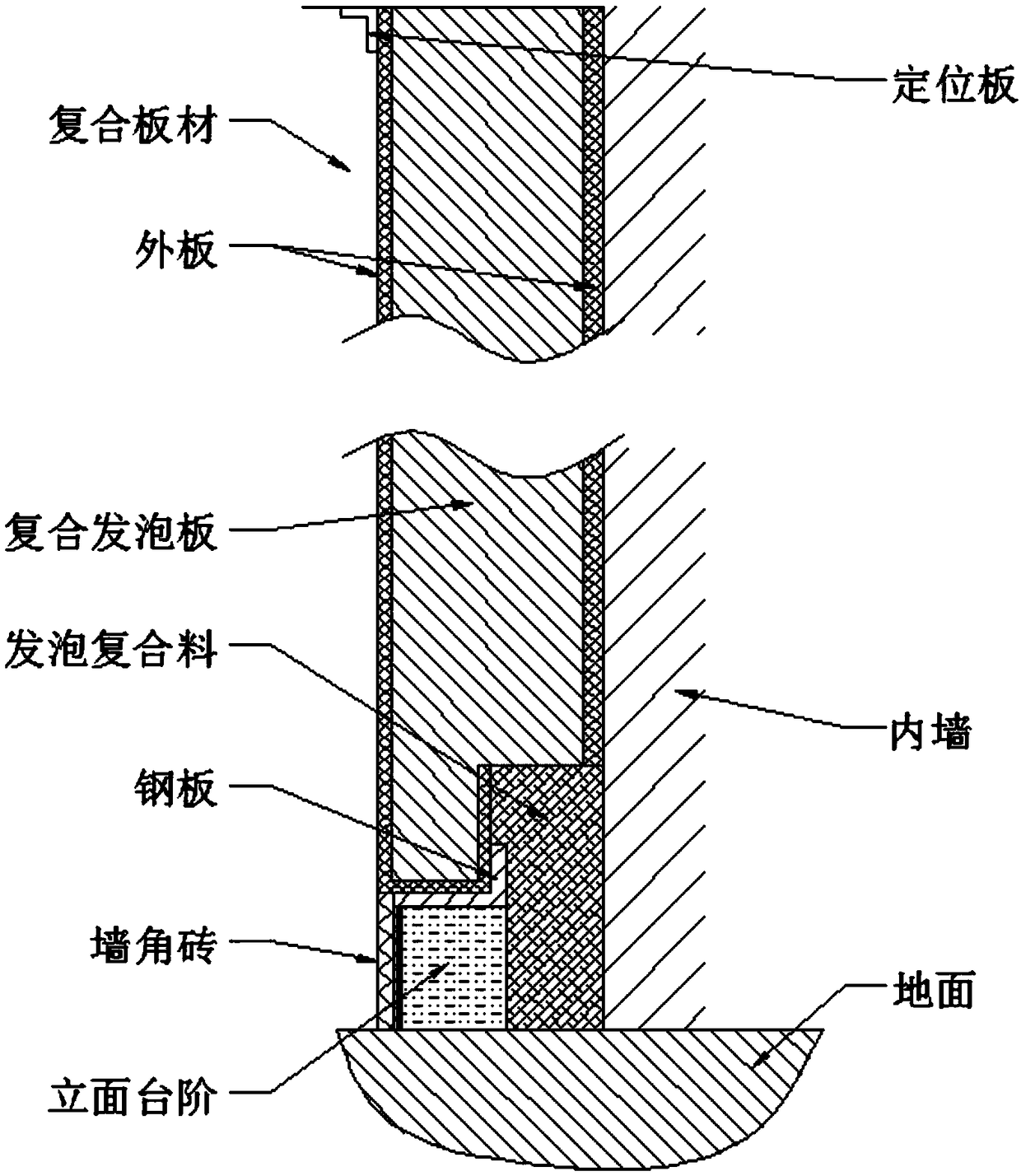

[0038] (1) First pour a facade step with concrete on the ground of the inner wall, leaving a gap between the facade step and the inner wall. After it is solidified and formed, install several L-shaped steps with screws on the top of the facade step. steel plate;

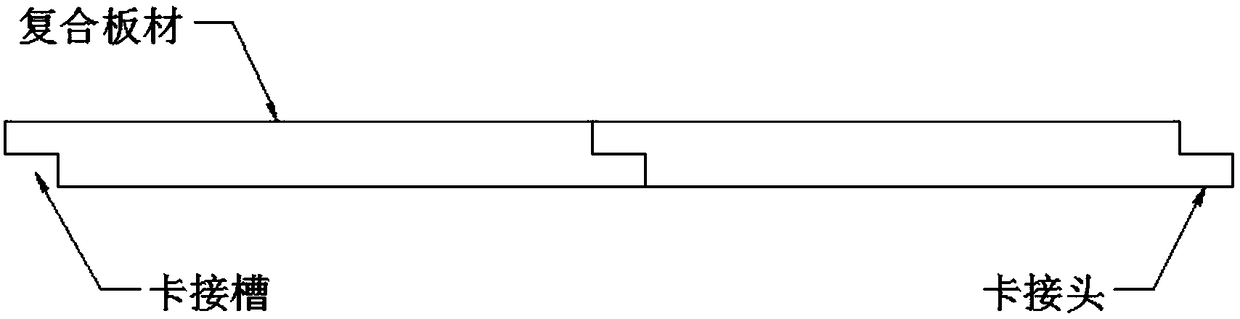

[0039] (2) Select the custom-made composite board, install it on the facade step by using the tongue and groove set on the bottom surface of the composite board and position it through the steel plate, and then install the second, third...Nth composite board in sequence from the side , the top surface of the composite panel is directly in contact with the ceiling and positioned through the positioning plate, and the inner surface of the composite panel is in contact with the inner wall;

[0040] (3) Punch a number of through holes on the side of the facade steps, the through holes are arranged horizon...

Embodiment 2

[0059] All the other are identical with embodiment 1, difference is:

[0060] In described step (3), filling time is controlled at 8s;

[0061] The foaming composite material includes material A, material B and straw, the material A is a combined polyether or basic phenolic resin, the material B is isocyanate or alkane with a low boiling point, and the straw accounts for The mass ratio is 58%, and the preparation method of the foamed compound is as follows:

[0062] (a) Straw treatment: first cut the straw into 4mm length segments, sieve to remove the ash generated during the straw cutting process, then send the straw into a high-temperature steam sterilization chamber for sterilization, and dry for later use;

[0063] (b) Mixing of straw and material A: uniformly mix the dried straw with material A to obtain material C, in which a certain amount of foaming agent is added, and then the material C is cooled, and its temperature is controlled at 5°C;

[0064] (c) Production o...

Embodiment 3

[0072] All the other are identical with embodiment 1, difference is:

[0073] In described step (3), filling time is controlled at 10s;

[0074] The foaming composite material includes material A, material B and straw, the material A is a combined polyether or basic phenolic resin, the material B is isocyanate or alkane with a low boiling point, and the straw accounts for The mass ratio is 60%, and the preparation method of the foamed compound is as follows:

[0075] (a) Straw treatment: first cut the straw into 5mm length segments, sieve to remove the ash generated during the straw cutting process, then send the straw to a high-temperature steam sterilization chamber for sterilization, and dry for later use;

[0076] (b) Mixing of straw and material A: uniformly mix the dried straw with material A to obtain material C, in which a certain amount of foaming agent is added, and then the material C is cooled, and its temperature is controlled at 2°C;

[0077] (c) Production of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com