Construction method for reinforcing underground outer wall formwork in complex limited space in a foundation pit

A technology with limited space and construction methods, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, infrastructure engineering, etc. construction issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

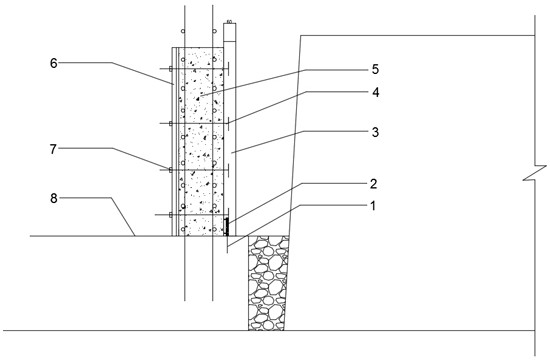

[0031] see Figure 1 to Figure 8 ,, the construction method for strengthening the underground external wall formwork in the complex confined space in the foundation pit, the construction method is carried out according to the following steps:

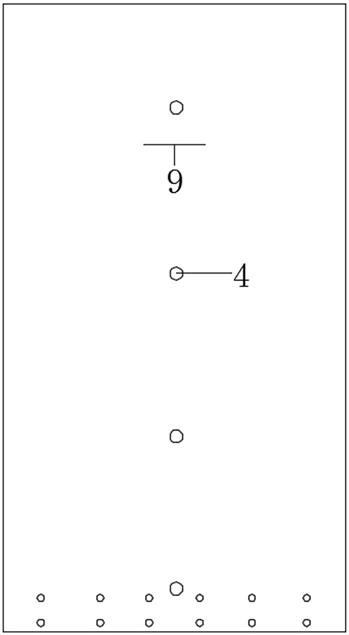

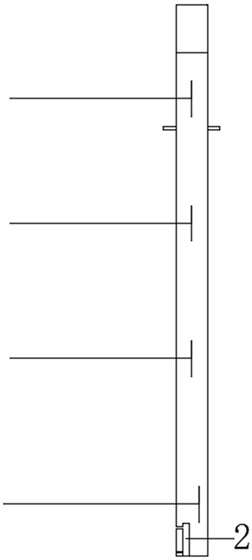

[0032] 1. Firstly, make the concrete prefabricated exterior wall formwork, the formwork width is 1200 mm, the height is the floor height, and the thickness is 60mm, with φ6 steel mesh inside. A grouting sleeve is arranged on the lower part of the prefabricated exterior wall formwork. When pre-embedding, it is necessary to pre-embed the reinforcement ring 9, such as figure 2 , image 3 Shown:

[0033] 2. Pre-embed each prefabricated exterior wall formwork according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com