Concrete filled steel tubular column steel-reinforced concrete beam ring beam joint formwork reinforcing piece and method

A technology of concrete-filled steel tube columns and steel-reinforced concrete, which is applied in the fields of formwork/formwork/work frame, construction components on-site preparation, construction, etc. It can solve problems such as the influence of steel bar installation, grout leakage, and exposed screw rods, etc., to achieve Save input costs, improve efficiency, and avoid impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

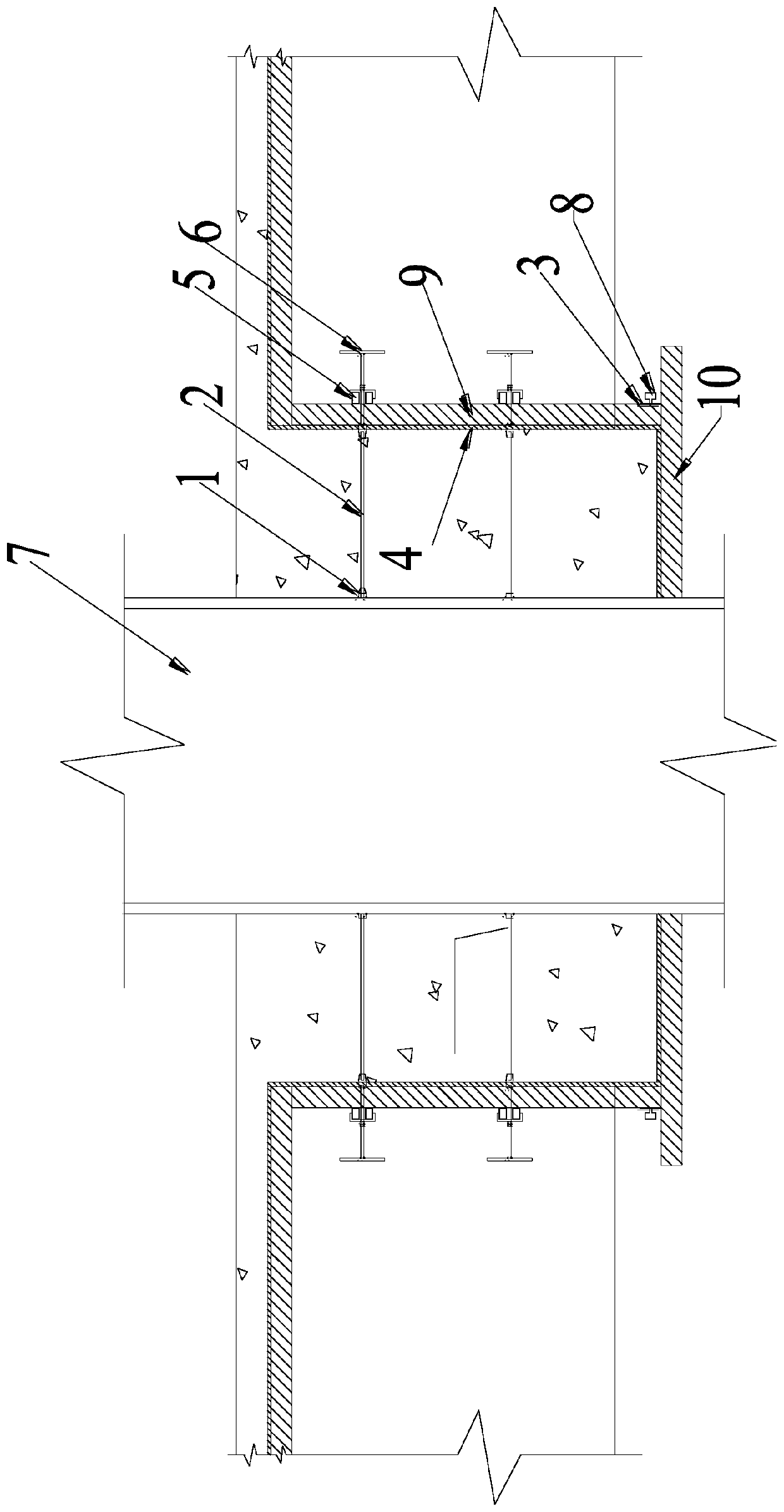

[0063] Specific embodiment one, such as Figure 1-8 As shown, a formwork reinforcement for steel reinforced concrete beam ring beam joints of concrete filled steel pipe columns includes a first tapered sleeve 1, a round steel tie rod 2, a steel flat belt 3, an arc formwork 4, and arc-shaped double pipes 5, T-shaped connecting rod 6;

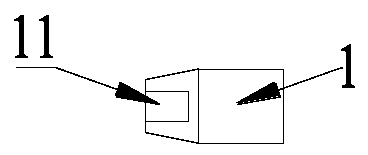

[0064] The first tapered sleeve 1 is welded to the steel column 7, and the first tapered sleeve is provided with several rows, and each row is evenly welded to the outer wall of the steel column; as figure 2 As shown, the first tapered sleeve 1 is an integral structure including a circular frustum sleeve and a cylindrical end, and the side of the cylindrical end close to the steel column is provided with a bevel, which is convenient for welding with the steel column 7; the first An internal thread 11 is provided inside the frustum sleeve of the tapered sleeve 1 .

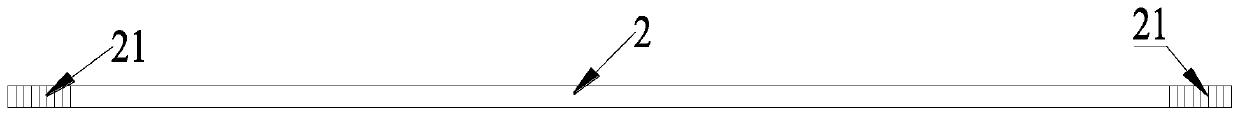

[0065] The round steel tie rod 2, such as image 3 As shown, both ends are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com