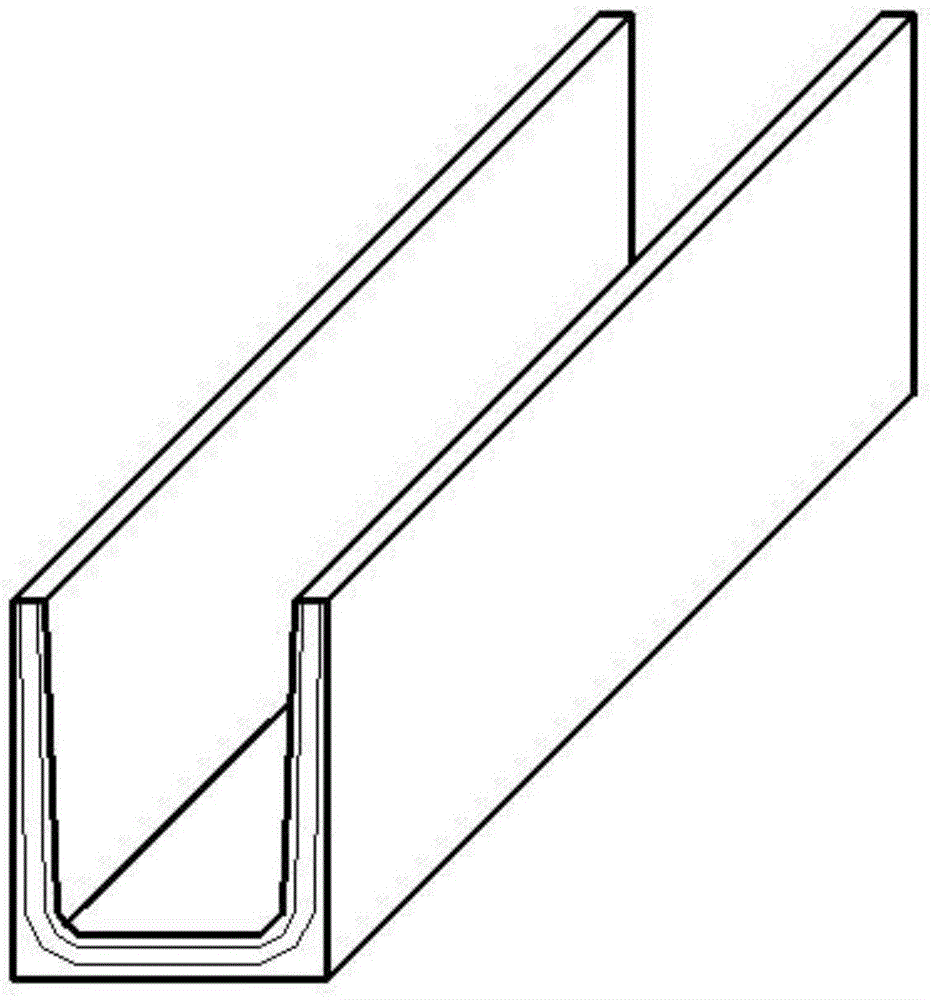

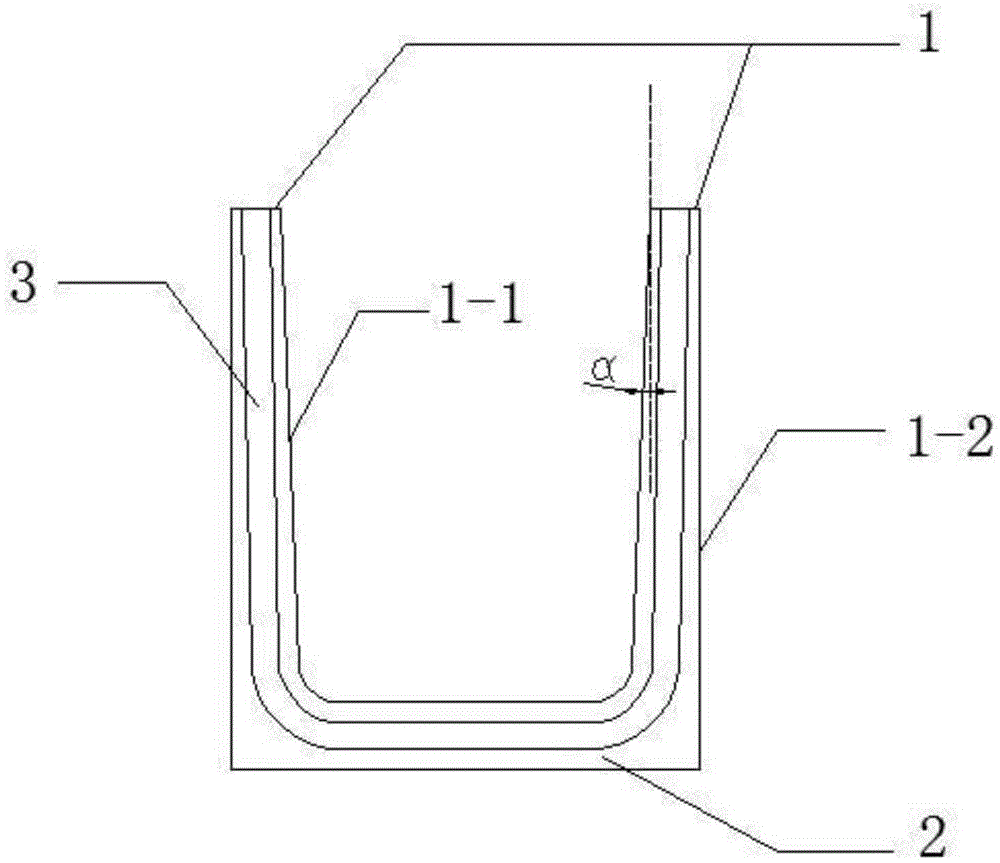

A kind of preparation method of 2m long light weight prefabricated concrete U-shaped channel

A technology of precast concrete and light concrete is applied in the field of preparation of 2m long light precast concrete U-shaped channels, which can solve the problems of low compressive strength of precast concrete U-shaped channels, only fixed-point production, and poor frost resistance, etc. Increased or reduced yield, less air bubbles, reduced noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the preparation method of a kind of 2m long light prefabricated concrete U-shaped channel of this embodiment is realized according to the following steps:

[0018] 1. Weigh 37%-40% gravel, 33%-35% sand, 13%-15% cement, 5%-6% fly ash, 2%-2.5% mineral powder, 0.2%-0.3% Silicon powder, 0.4%-0.5% admixture, 0.2%-0.3% steel fiber and 7%-8% water are used as raw materials;

[0019] 2. Add the raw materials weighed in step 1 into the mixer, stir for 2 minutes and pour directly into the U-shaped channel mold placed on the level ground to obtain a formed 2m long light concrete U-shaped channel;

[0020] 3. Transport the U-shaped channel mold carrying the formed 2m-long light concrete U-shaped channel to the curing site, put it into a closed curing space, and inject steam into the closed curing space for curing. The curing process is: first Stop at room temperature for 4 hours, and then pass in steam for 6 hours, in which the temperature in the curing sp...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the label of the cement described in step one is PO425. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the grade of the fly ash mentioned in step 1 is Grade I. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com