Environment-friendly fair-faced concrete pumping agent and preparation method thereof

A technology of fair-faced concrete and pumping agent, which is applied in the field of concrete additives, and can solve problems such as easy bleeding of concrete, slump retention and water reduction effects need to be further improved, and poor frost resistance, so as to improve honeycomb pockmarking, Guaranteed workability and fluidity, slump retention and water-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

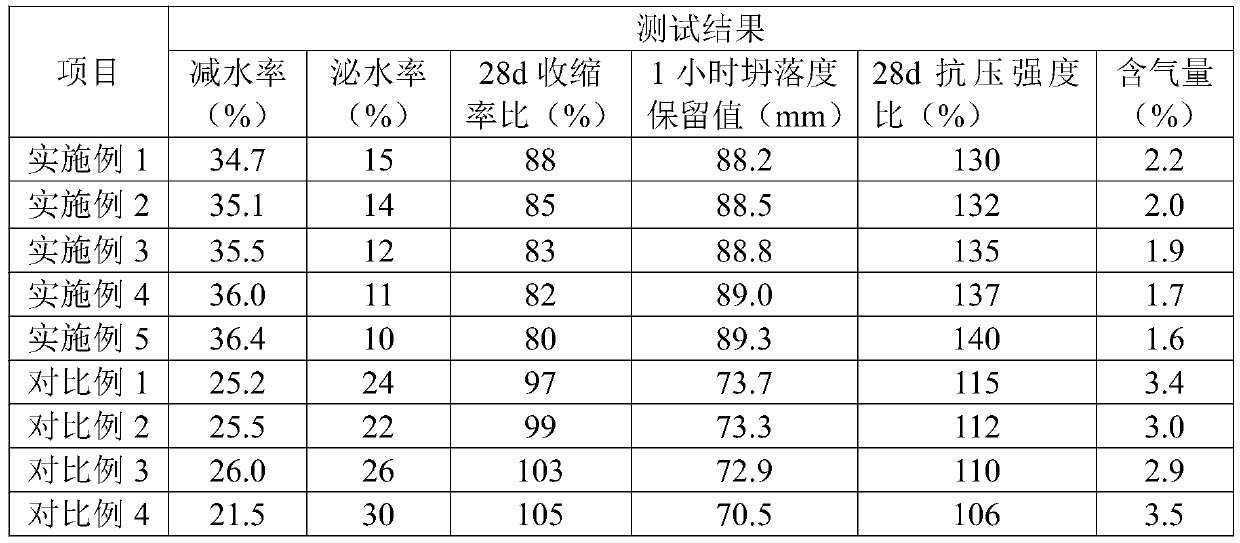

Examples

Embodiment 1

[0031]An environment-friendly clear-water concrete pumping agent is characterized in that it comprises the following components in parts by weight: 1 part of epoxy-based single-terminated silicone oil modified casein, dihydro-2,4,6-trioxo -1,3,5-triazine-1,3(2H,4H)-dipropionic acid / 2-(diethanolamino)ethanesulfonate polycondensate 30 parts, humic acid 2 parts, phosphate modified starch 0.1 part, 0.2 part of simethicone oil, 0.5 part of magnesite powder, 0.5 part of sodium sucrose octasulfate, and 35 parts of water; the particle diameter of the magnesite powder is 300 mesh.

[0032] The preparation method of the epoxy mono-capped silicone oil modified casein comprises the following steps: adding epoxy mono-capped silicone oil, casein and sodium hydroxide to the mixed solvent, stirring and reacting at 80°C for 4 hours , followed by rotary evaporation to remove the solvent, and then washed with water for 3 times, and finally placed in a vacuum drying oven at 85° C. to dry to const...

Embodiment 2

[0036] An environment-friendly clear-water concrete pumping agent is characterized in that it comprises the following components in parts by weight: 1.5 parts of epoxy-based single-terminated silicone oil modified casein, dihydro-2,4,6-trioxo -1,3,5-triazine-1,3(2H,4H)-dipropionic acid / 2-(diethanolamino)ethanesulfonate polycondensate 33 parts, humic acid 2.5 parts, phosphate modified starch 0.15 parts part, 0.3 part of emulsified silicone oil, 0.7 part of magnesite ore powder, 0.7 part of sodium sucrose octasulfate, and 37 parts of water; the particle diameter of the magnesite ore powder is 350 mesh.

[0037] The preparation method of the epoxy mono-terminated silicone oil modified casein comprises the following steps: adding epoxy mono-terminated silicone oil, casein and sodium hydroxide to the mixed solvent, stirring and reacting at 83°C for 4.5 hours , followed by rotary evaporation to remove the solvent, and then washed with water for 4 times, and finally placed in a vacuu...

Embodiment 3

[0041] An environment-friendly clear-water concrete pumping agent is characterized in that it comprises the following components in parts by weight: 2 parts of epoxy-based single-terminated silicone oil modified casein, dihydro-2,4,6-trioxo -1,3,5-triazine-1,3(2H,4H)-dipropionic acid / 2-(diethanolamino)ethanesulfonate polycondensate 35 parts, humic acid 3 parts, phosphate modified starch 0.2 part, 0.35 part of simethicone oil, 1 part of magnesite powder, 1 part of sodium sucrose octasulfate, and 40 parts of water; the particle diameter of the magnesite powder is 400 mesh.

[0042] The preparation method of the epoxy mono-terminated silicone oil modified casein comprises the following steps: adding epoxy mono-terminated silicone oil, casein and sodium hydroxide to the mixed solvent, stirring and reacting at 85°C for 5 hours , followed by rotary evaporation to remove the solvent, then washed with water for 5 times, and finally placed in a vacuum drying oven at 90° C. to dry to co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com