Automobile speed change control mechanism

A control mechanism and automobile technology, applied in the direction of mechanical equipment, toothed components, belts/chains/gears, etc., can solve the problems of the driver mistakenly engaging the reverse gear, cumbersome operation, easy shaking, etc., and achieve the interlocking function , feel the obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

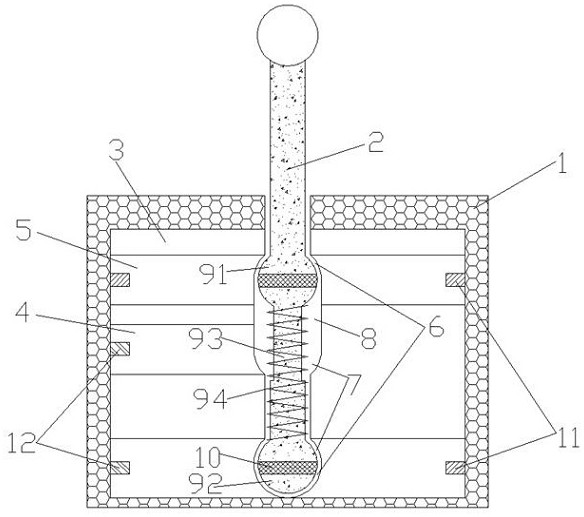

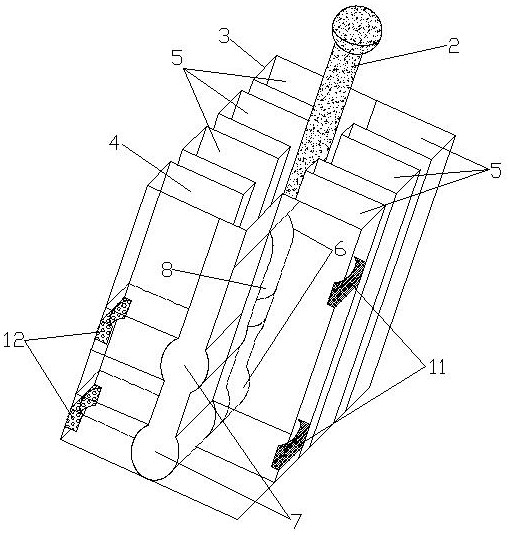

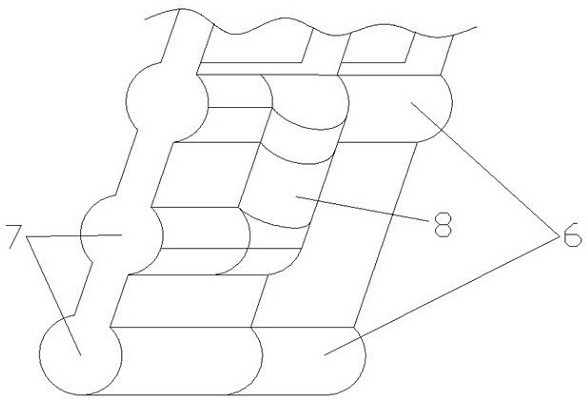

[0019] Embodiment 1: see Figure 1~Figure 4 , an automobile transmission control mechanism, comprising an operating base 1, a joystick 2, the inside of the operating base 1 is provided with a gear limit disc 3, and the gear limit disc 3 is provided with a reverse gear slot 4 and a plurality of forward gear slots 5 , the forward gear grooves 5 are symmetrically arranged and parallel to each other, the reverse gear grooves 4 are located on one side of the forward gear grooves 5 and are arranged in parallel with the forward gear grooves 5; the forward gear grooves 5 communicate with each other through the forward guide grooves 6 arranged horizontally, A reverse guide groove 7 arranged horizontally is arranged in the groove 4 .

[0020] The joystick 2 is inserted into the forward guide groove 6, and the bottom of the joystick 2 is provided with a guide block 9. The guide block 9 includes an upper guide block 91, a lower guide block 92, a telescopic rod 93 and a compression spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com