Method for eliminating defects in image and printer by using the method

A technology that changes the print head and method. It is used in the field of masking or reducing misalignment defects. It can solve the problems of lowering printing speed and shortening the drying time of media, so as to achieve the effect of high printing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

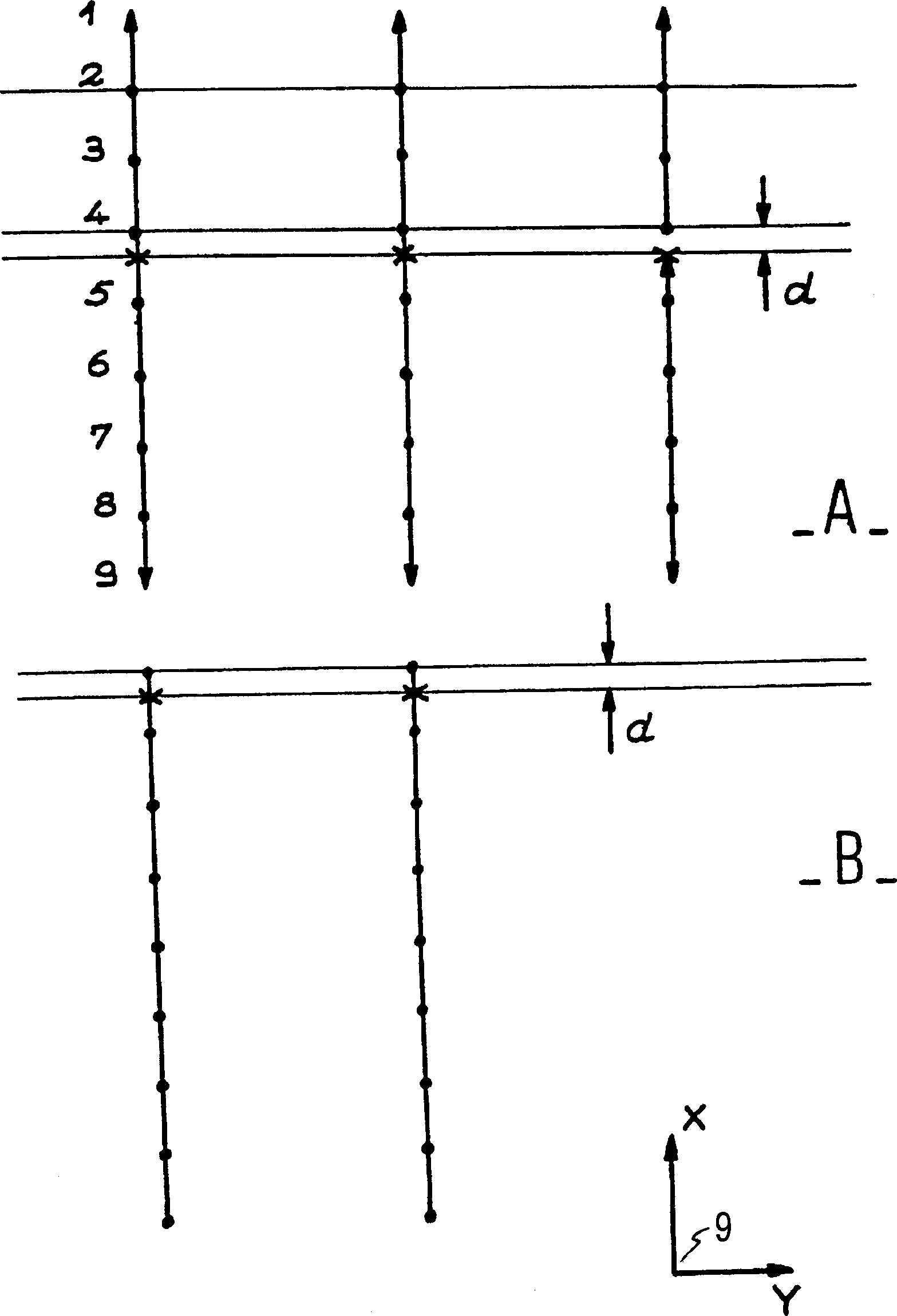

[0037] image 3 is to illustrate the difference due to the algebraically added noise voltage. That is, representing nine different nominal positions of the ink droplets formed by the pulses of the ink droplets in a marked frame, and representing the different shapes on the plane of the media represented by the XY axis. In order to make the explanation easy to understand, nine ink droplets are shown in this embodiment, and their intervals are enlarged.

[0038] exist image 3 In part A of the three frames, nine ink droplets numbered 1 to 9 are represented as dots at their nominal positions. These three frames form part of the same stripe A. It is assumed that there is a systematic deviation of the actual position of the ink drop 4 towards the ink drop 5 . The actual position is represented in the form of a cross. The distance d between the actual position and the nominal position of the ink droplet in row 4 results in a image 3 The white misalignment defect in part A is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com