Automatic concrete proportioning device for municipal building construction

A technology for building construction and concrete, which is applied to clay preparation devices, mixing operation control devices, batching and batching instruments, etc., can solve problems such as uneven proportioning, lack of pre-mixing of materials, etc., to save operating steps, improve safety, The effect of reducing the rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

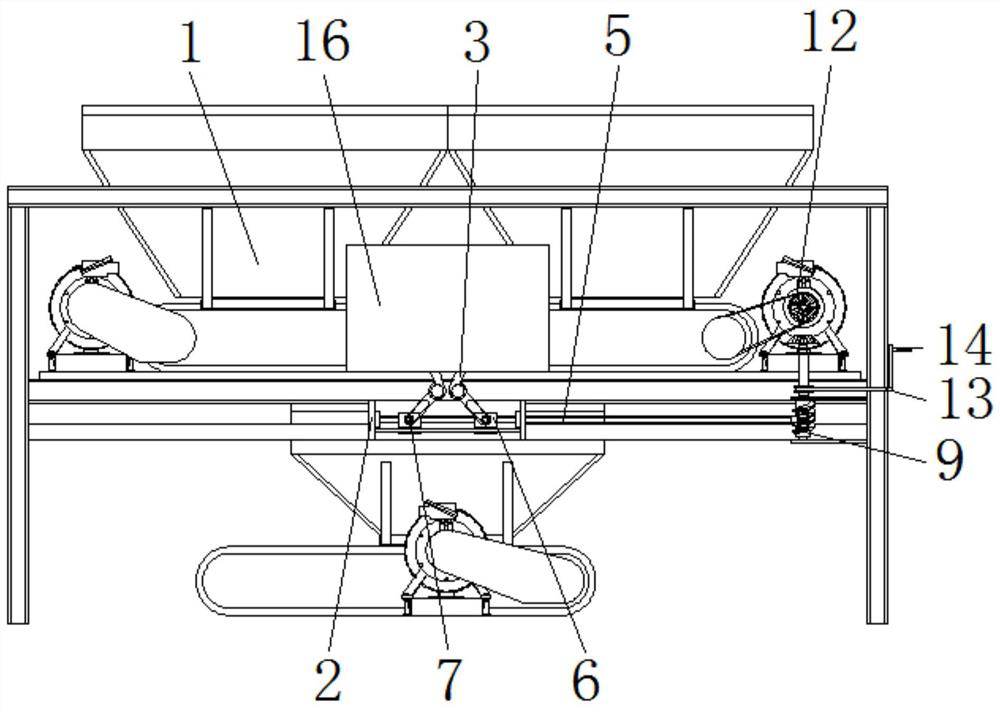

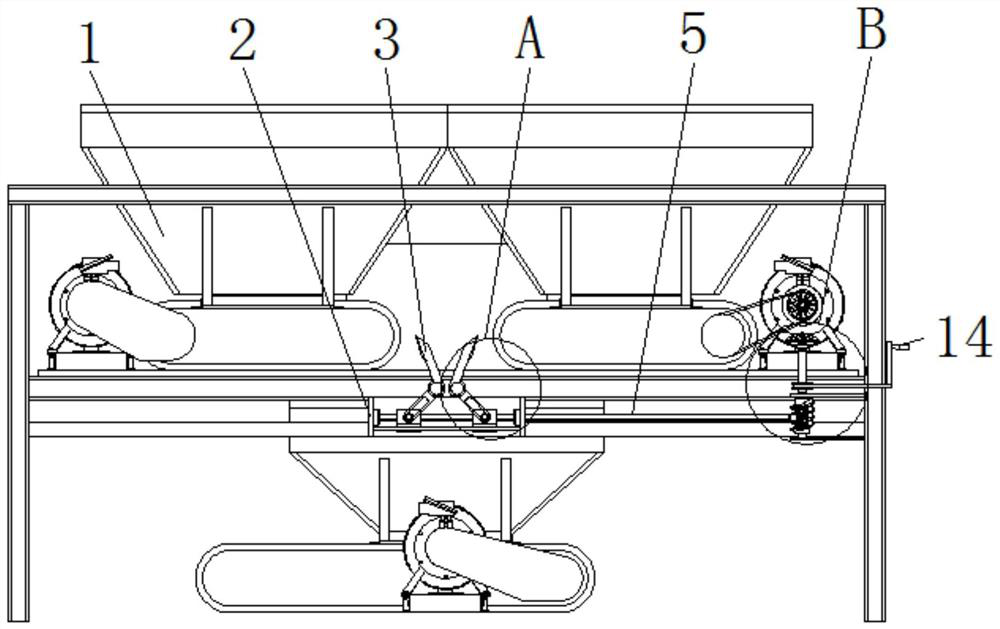

[0035] like Figure 1 to Figure 5 As shown, a kind of automatic concrete proportioning device for municipal building construction provided by the present invention comprises a proportioning device body 1;

[0036] The connection frame 2 fixed on the front of the proportioning device body 1;

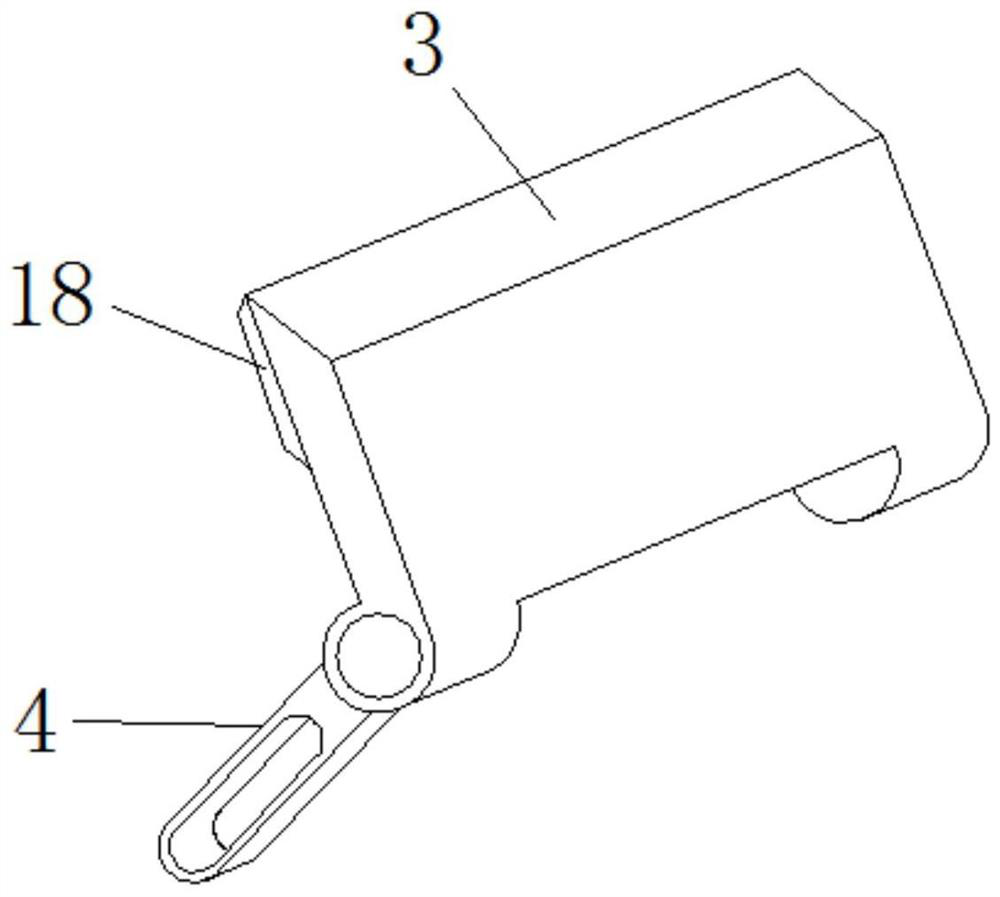

[0037] The left and right sides of the proportioning device body 1 are movably connected with a guide plate 3 through pin shafts, the guide plate 3 is located on the inner side of the two discharge ends of the proportioning device body 1, and the bottom of the front side of the guide plate 3 is fixedly connected with a swing rod 4. The inside of the connection frame 2 is provided with a two-way screw 5, and the left and right sides of the two-way screw 5 are threadedly connected with a screw sleeve 6, and the front of the screw sleeve 6 is fixedly connected with a traction rod 7 located inside the swing rod 4, and the traction The rod 7 and the swing rod 4 are slidingly connected, and th...

Embodiment 2

[0053] like Image 6 and Figure 7 As shown, in the second embodiment, other structures remain unchanged, and the present invention provides another proportioning device body 1, including a vertical plate 19 fixed on the right side of the front side of the proportioning device body 1, and the right side of the vertical plate 19 A transmission plate 20 is provided, and the top and bottom of the transmission plate 20 are fixedly connected with an insertion rod 21. The left end of the insertion rod 21 runs through the vertical plate 19 and extends to the left side of the vertical plate 19. The left side of the transmission plate 20 is fixedly connected with a The compression spring 22 sleeved on the surface of the insertion rod 21, the surface of the insertion rod 21 is threadedly connected with the nut 23 located on the left side of the vertical plate 19, the surface of the connecting plate 13 is provided with a through hole 24, and the right end of the insertion rod 21 runs thr...

Embodiment 3

[0057] like Figure 8 and Figure 9 Shown, in present embodiment three, other structures remain unchanged, the present invention provides another kind of cleaning piece 18, comprises the bottom plate 26 that is fixed on the right side of cleaning piece 18, and the top of guide plate 3 is provided with trapezoidal groove 27, and bottom plate The right side of 26 is fixedly connected with the trapezoidal block 28 that is positioned at the inside of the trapezoidal groove 27, the trapezoidal groove 27 and the trapezoidal block 28 are slidingly connected, the inboard of the guide plate 3 is provided with a bolt 29, and the end of the bolt 29 near the guide plate 3 runs through the guide plate 3 and Extending to the inside of the trapezoidal groove 27 , the guide plate 3 is screwed to the bolt 29 , and the bolt 29 is located at the top of the trapezoidal block 28 .

[0058] By arranging the bottom plate 26, the trapezoidal groove 27 and the trapezoidal block 28, it is convenient f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com