Direct use of submerged arc furnace powder and different-particle-size and different-ratio feeding

A submerged arc furnace and feeding technology, which is applied to furnaces, furnace components, lighting and heating equipment, etc., can solve the problems affecting the insertion depth of smelting electrodes, the influx of molten liquid, and poor air permeability, which is conducive to safe production and improvement of furnace conditions. , to ensure the effect of breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

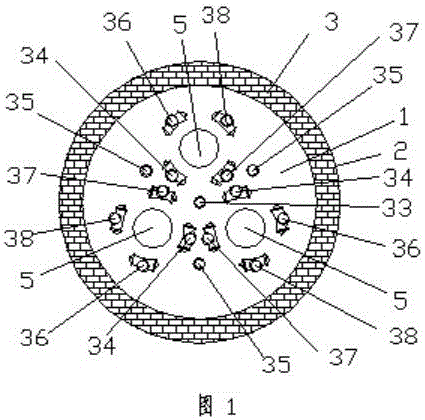

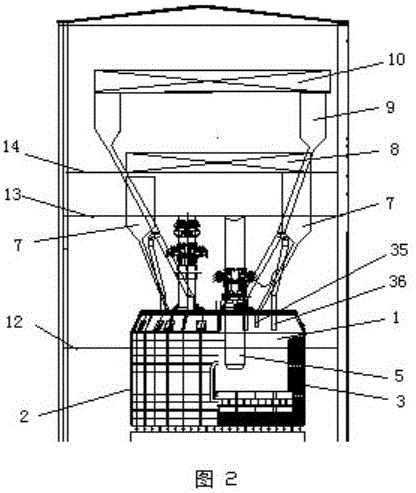

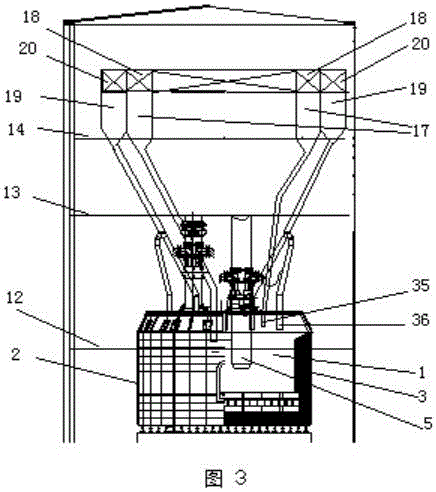

[0027] 1) When designing the feeding system of the submerged thermal electric furnace, adopt dual-system or multi-system feeding, and the feeder or ring distributor adopts the upper and lower double-layer design (attached figure 2 ), or the double-feed design of the inner and outer rings on the same layer (attached image 3 ), or use the large powder silo (32) to feed (attached Figure 4 ), adding a single powder or a reducing agent-containing proportioning mixture of a powder, a lump or a reducing agent-containing proportioning mixture of agglomerates, respectively into the predetermined feeding pipe (33) (34) through different feeding systems ( 35) (36) (37) (38); or the raw materials of different grades or different proportions are passed through the feeding pipes (33) (34) (35) (36) (37) ( 38) Add the hearth (1).

[0028] 2) According to the feeding amount of a certain raw material, it is possible to use unequal material pipe diameters, or adjust the height of the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com