Cyclone generator

A generator and cyclone technology, applied in the field of aerodynamics, can solve the problems of low suction, high noise, and inability to absorb dust, and achieve the effect of improving the effect of absorbing oil fume, solving the problem of low suction, and increasing the suction distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0023] The invention discloses a cyclone generator.

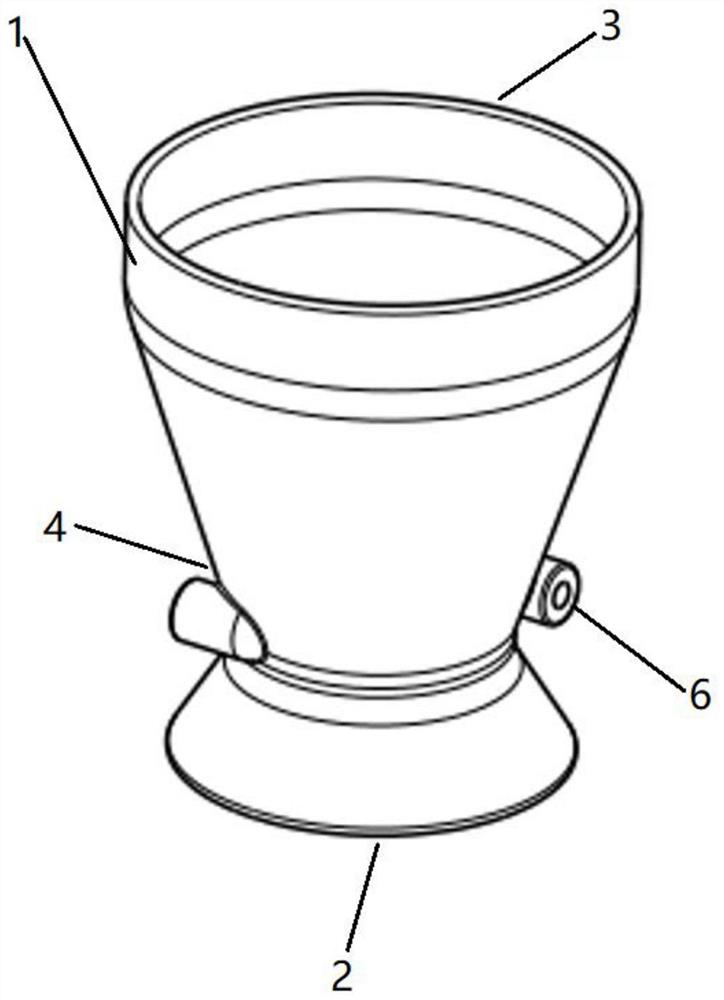

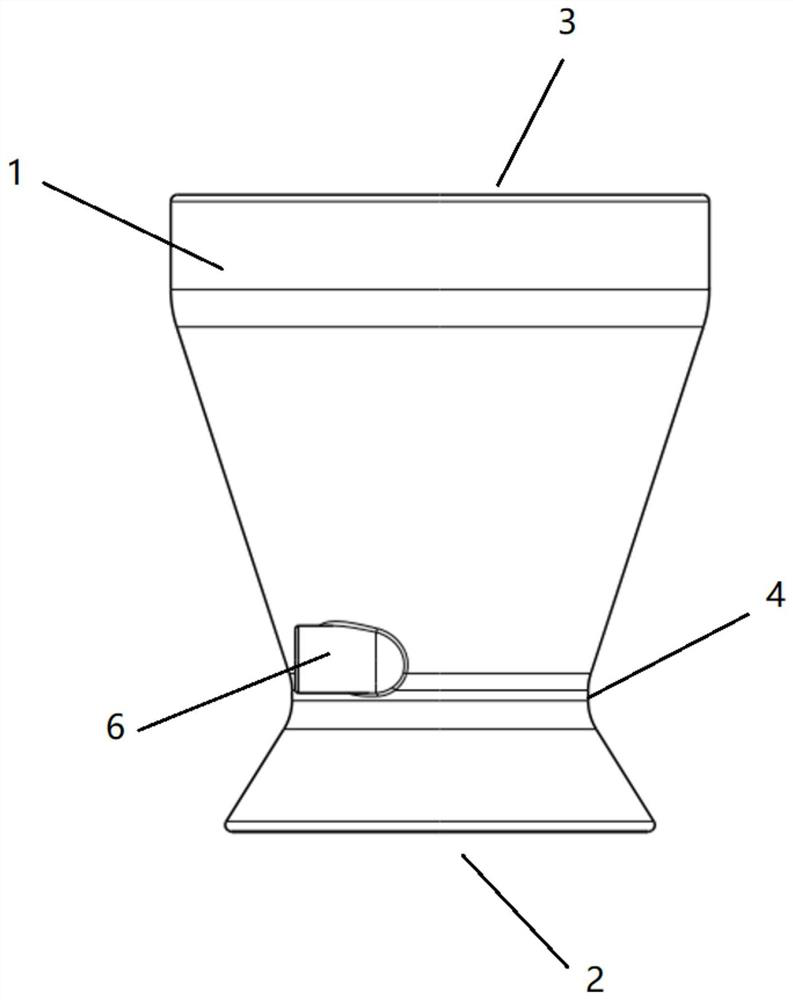

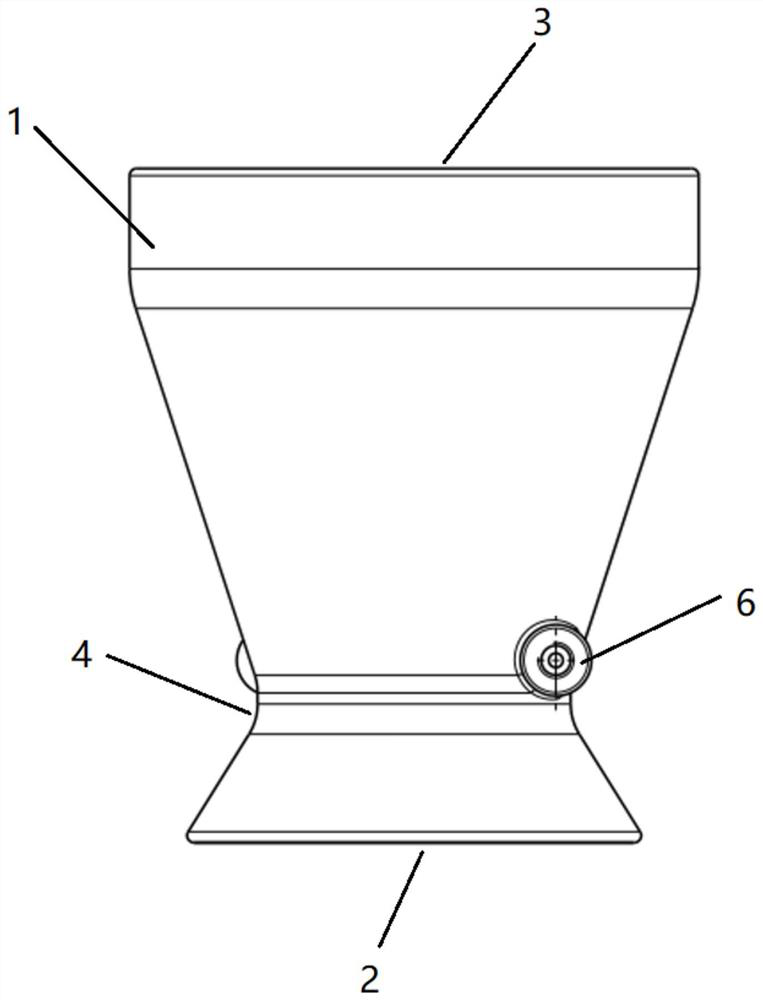

[0024] Such as Figure 1 to Figure 5 As shown, the cyclone generator includes a generation pipeline 1, the generation pipeline 1 includes an air inlet 2 and an air outlet 3, the air outlet 3 is sealed and connected with the suction pipeline, and the generation pipeline 1 is contracted at one end close to the air inlet 2 to form a contraction Mouth 4.

[0025] In addition, the generating duct 1 is provided with a tangential air inlet 5 at the constriction port 4, and the air supply pipe 6 corresponding to the tangential air inlet 5 is integrally formed at the constriction port 4 of the generating duct 1, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com