Metal part forming equipment

A technology for forming equipment and metal parts, which is applied in the field of forming equipment for screw forming, and can solve the problems of heavy oil pollution on the conveyor belt surface and residual cooling oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

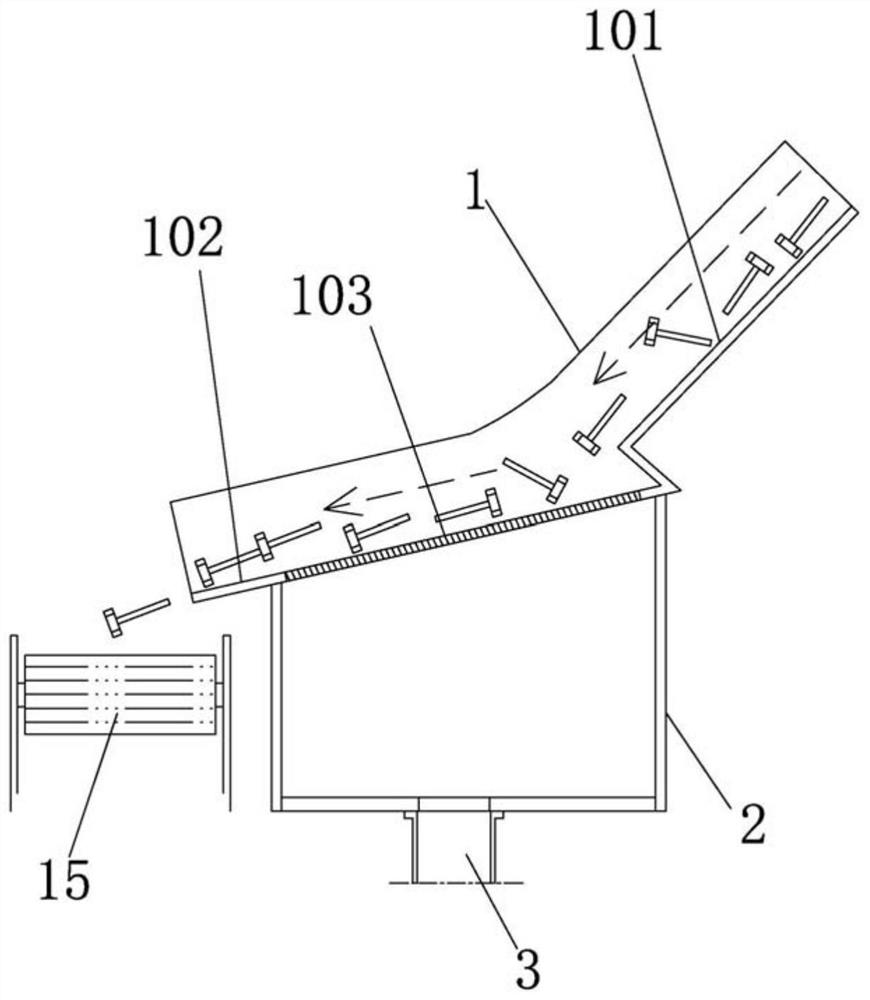

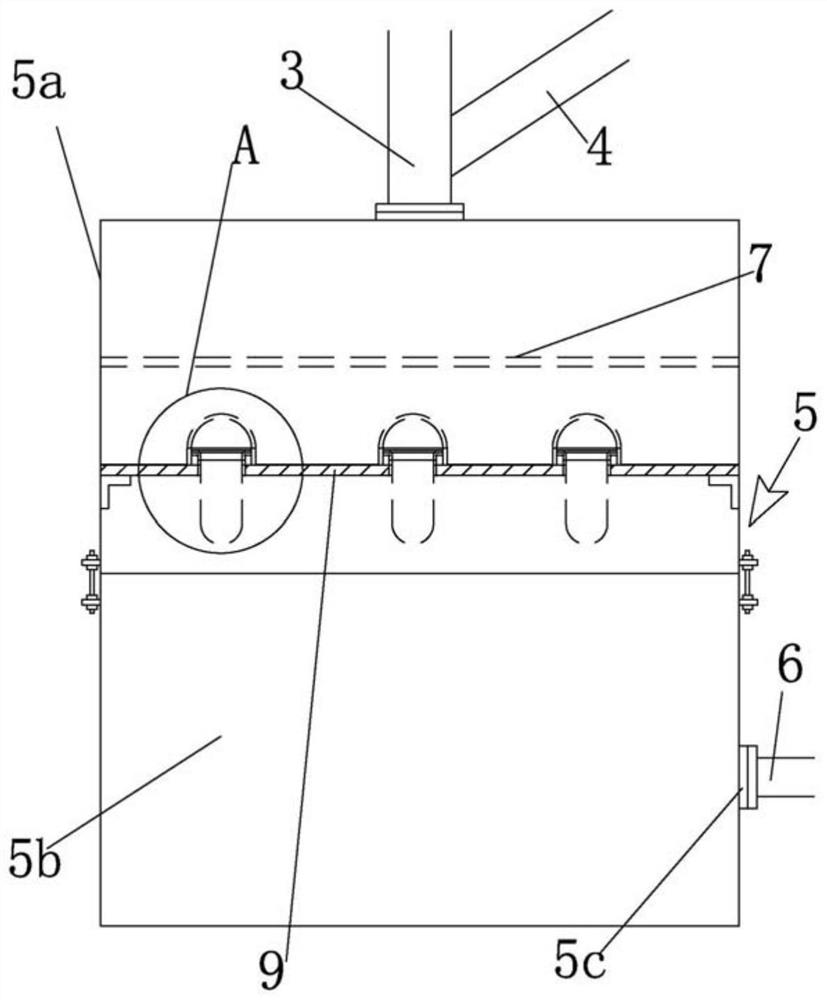

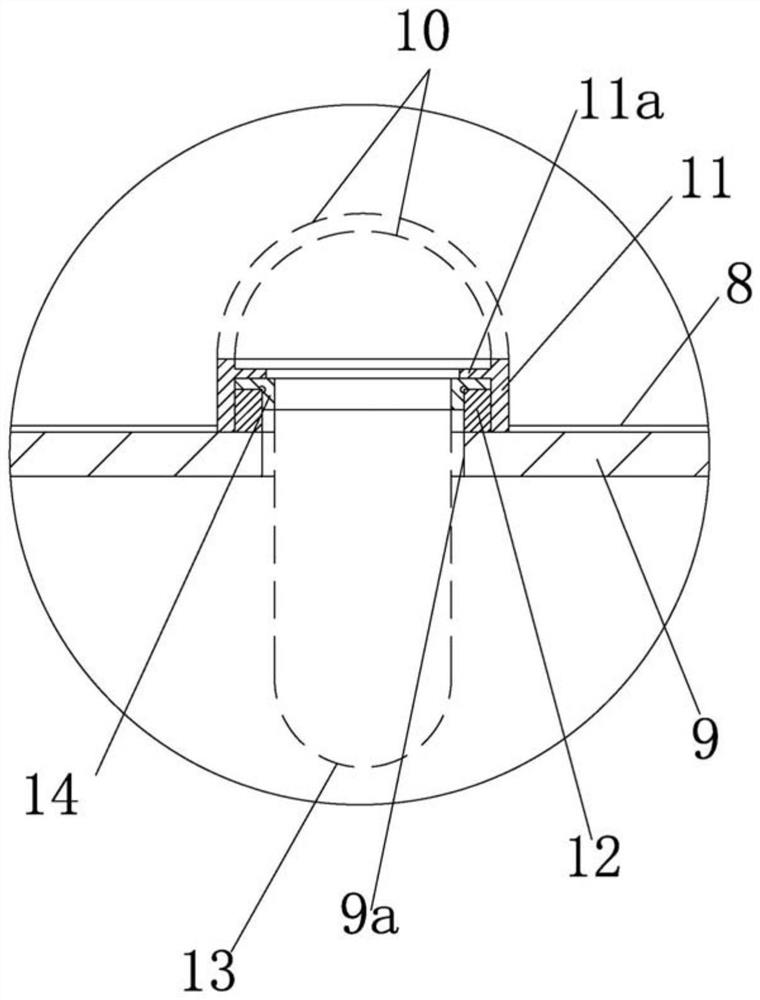

[0030] Attached below Figure 1-3 The present invention is further illustrated with specific examples.

[0031] Such as figure 1 As shown, a metal part forming equipment includes a blanking guide seat 1 set on the blanking side of the equipment, and a conveyor belt 15 for conveying screws, which is directly below the discharge port on the lower side of the blanking guide seat 1. The material guide seat 1 is provided with a guide groove for guiding the sliding direction of the screw.

[0032] The guide groove bottom surface of the above-mentioned blanking guide seat 1 includes:

[0033] A first inclined bottom surface 101 inclined downward along the blanking direction;

[0034] The second inclined bottom surface 102 inclined downward along the blanking direction, the highest end of the second inclined bottom surface 102 is directly below the lowest end of the first inclined bottom surface 101, the lowest end of the second inclined bottom surface 102 is directly above the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com