Humidity control type premixed dry-mixed mortar drying equipment

A technology for ready-mixed dry powder and drying equipment, applied in drying, dryer, lighting and heating equipment and other directions, can solve the problems of dry powder mortar drying effect, poor efficiency, insufficient drying, uneven heating, etc. To achieve the effect of improving drying efficiency and effect, improving drying effect and improving contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

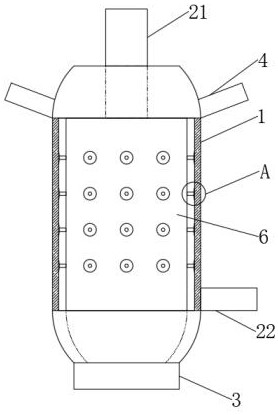

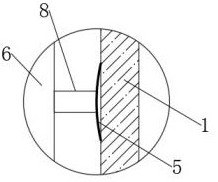

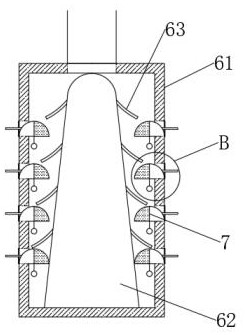

[0041] See Figure 1-4, a kind of wet control type ready-mixed dry powder mortar drying equipment, including drying box 1, drying box 1 upper and lower ends are fixed to connect the intake pipe 21 and the collection box 3, the drying box 1 side wall is fixedly connected to the outlet pipe 22 and a plurality of feed pipes 4, the drying box 1 is fixedly connected to the upper end of the air duct 6, and the air inlet pipe 21 is connected to the upper end of the air table 6, the drying box 1 and the air table 6 are provided with a ring gap, and the feed pipe 4 and the outlet pipe 22 are located on the upper and lower sides of the annular gap, respectively, There is a plurality of evenly distributed hot air vents on the air table 6, the hot air vent opening is fixedly connected to the isolation net 10, the inner side of the hot air hole is fixedly connected to the control wind cover 7, the air control cover 7 is close to the isolation net 10 One end is fixedly connected to the wet bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com