A temperature control blanking system

A temperature control and blanking technology, applied in the combustion method, combustion type, incinerator, etc., can solve the problems of complex waste composition, difficult to control the combustion process and sufficient combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

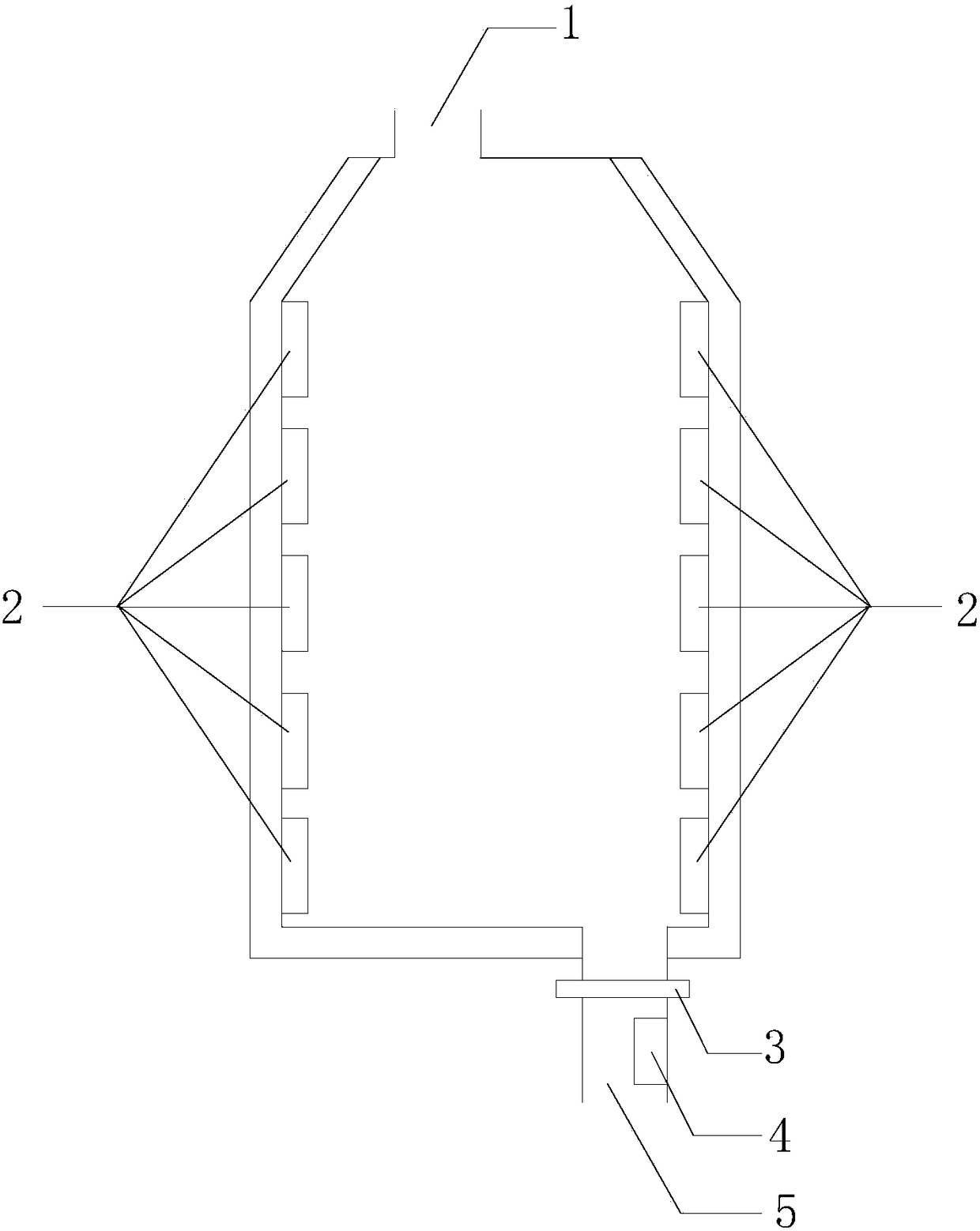

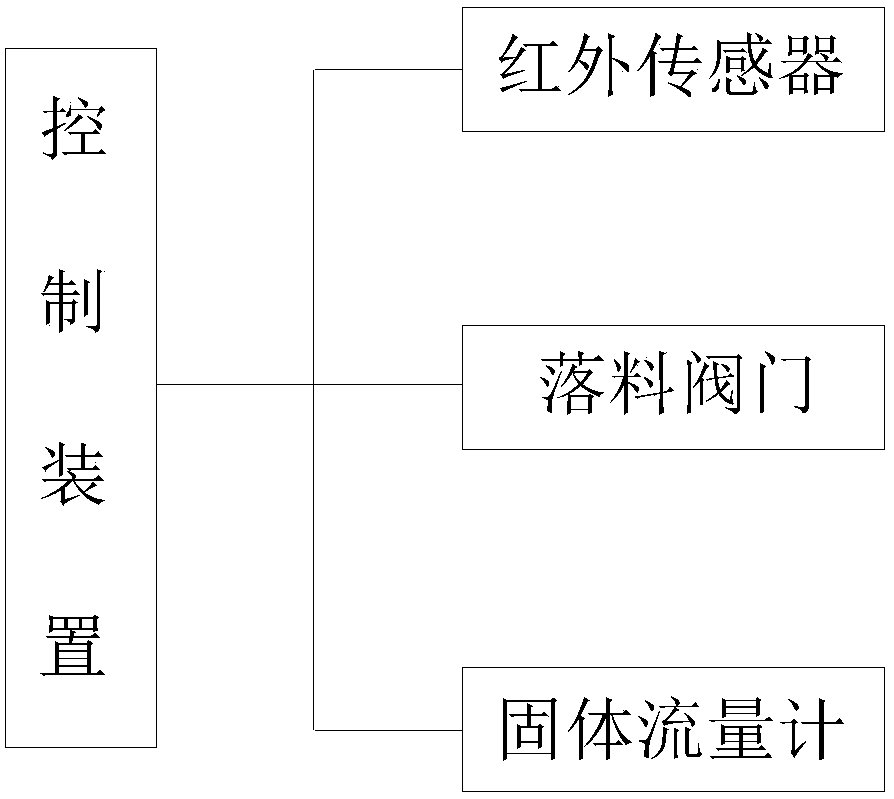

[0022] Such as figure 1 , figure 2 as shown, figure 1 , figure 2 It is a temperature control blanking system proposed by the present invention.

[0023] refer to figure 1 , figure 2 , the temperature control blanking system proposed by the present invention includes: a combustion chamber, a detection device, a blanking device and a control device;

[0024] The top of the combustion chamber has a feed port 1 for feeding, and the bottom of the combustion chamber has a discharge port 5 for blanking;

[0025] A detection device is used to detect the temperature distribution in the combustion chamber;

[0026] The blanking device works according to the instructions of the control device;

[0027] The control device is connected in communication with the detection device and the blanking device;

[0028] The temperature distribution is preset in the control device, and the control device acquires the temperature distribution in the combustion chamber detected by the detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com