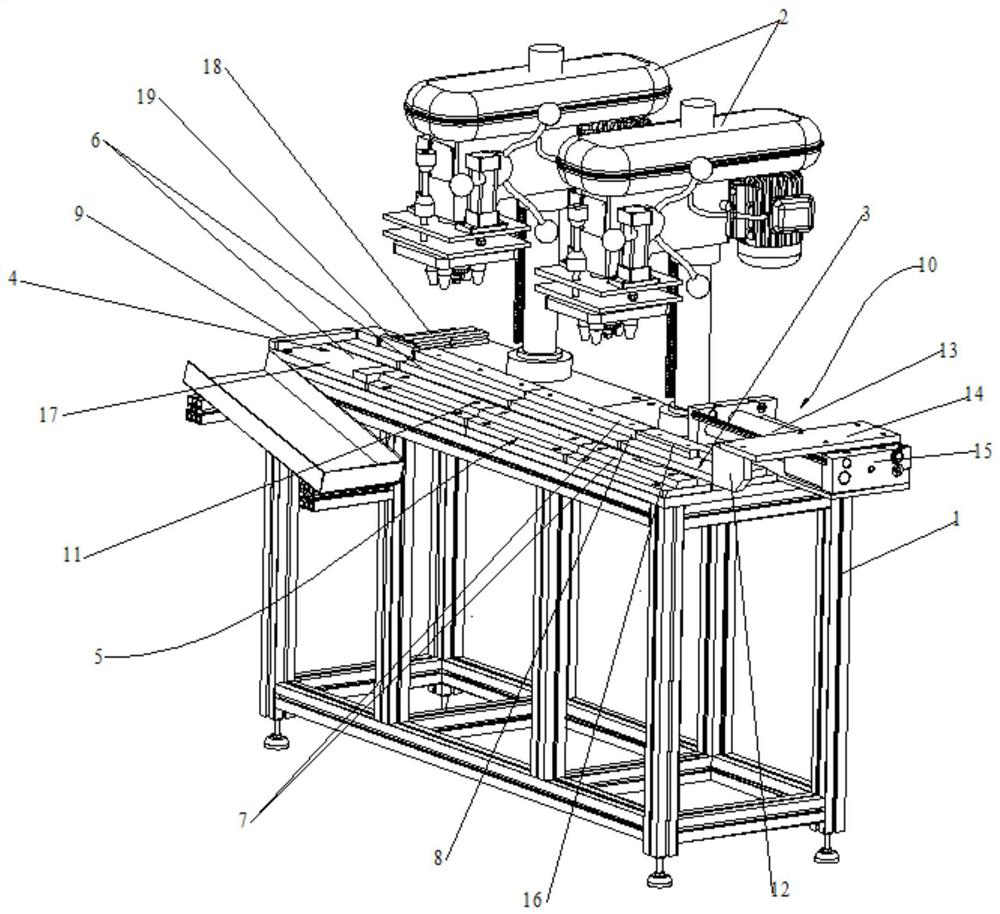

Multi-station drilling equipment

A drilling equipment, multi-station technology, applied in drilling/drilling equipment, metal processing equipment, boring/drilling and other directions, can solve the problems of complicated mechanical action and complex structure, and achieve simple structure and simplified mechanical Action, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

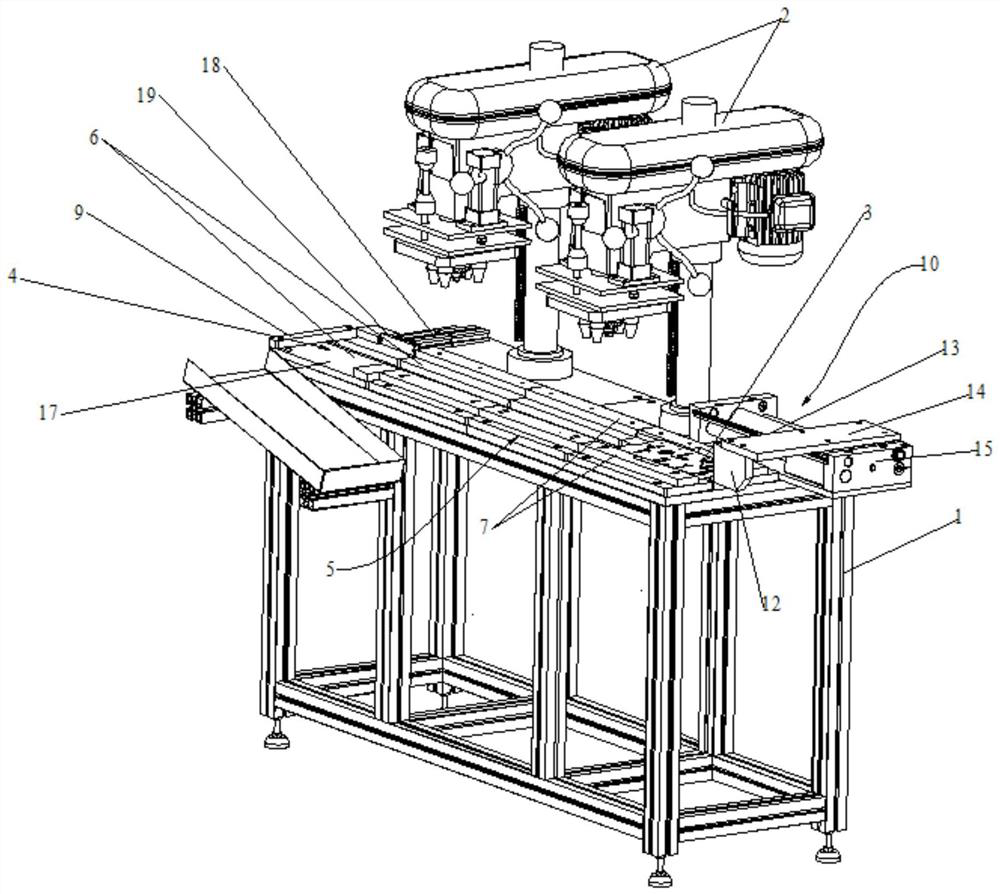

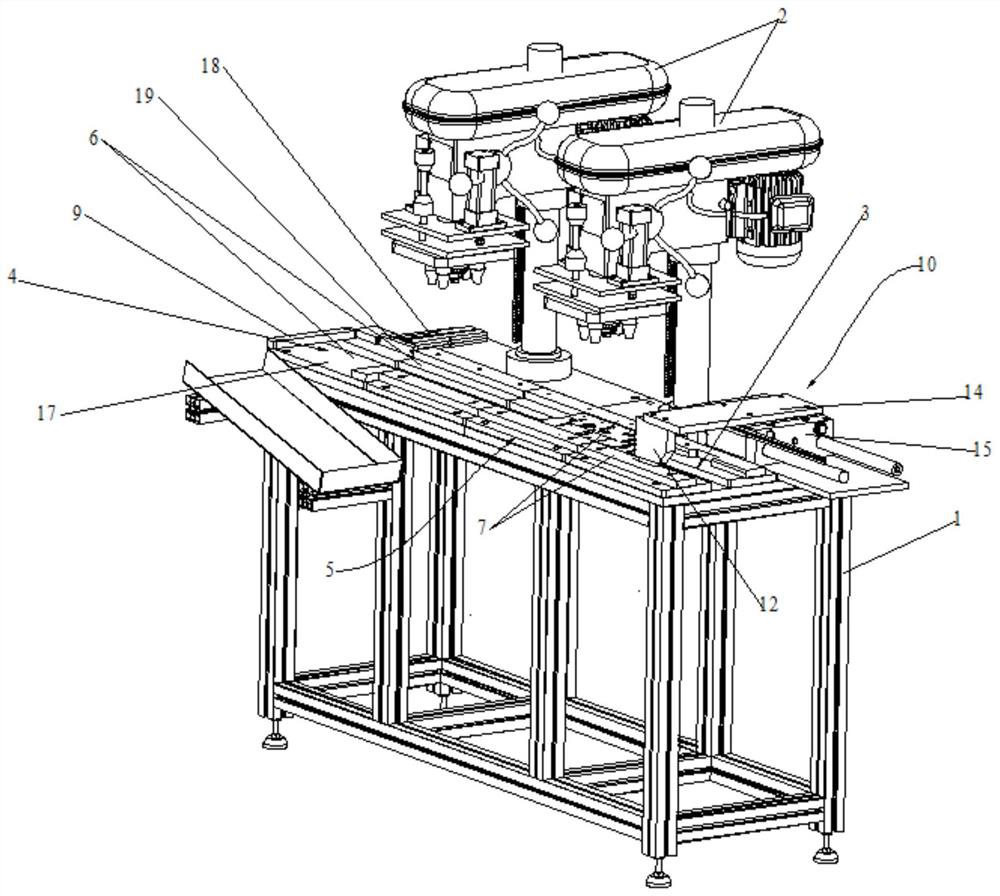

[0038] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0039] Such as figure 1Shown, be the embodiment of the two stations of multi-station drilling equipment of the present invention, comprise frame 1, at least two drilling machines 2 that are respectively arranged on the different stations on described frame 1; Set On the frame 1, there is a feeding end 3 and a feeding end 4, which are used to send the workpiece from the feeding end 3 to the transmission mechanism 5 of the feeding end 4 after passing through different stations. Wherein, the transmission mechanism 5 has a pair of supporting pads 6 fixedly installed on the frame 1, and its upper surface is used as a supporting device for workpieces to slide; The conveying direction of the workpieces is arranged symmetrically on both sides of the conveying direction. The upper surfaces of the supporting pads 6 on both sides are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com