Multi-station drilling production line

A production line and multi-station technology, applied in the direction of boring/drilling, drilling/drilling equipment, positioning devices, etc., can solve problems such as complex structure and complicated mechanical actions, and achieve simplified mechanical actions, simple structure, and improved The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

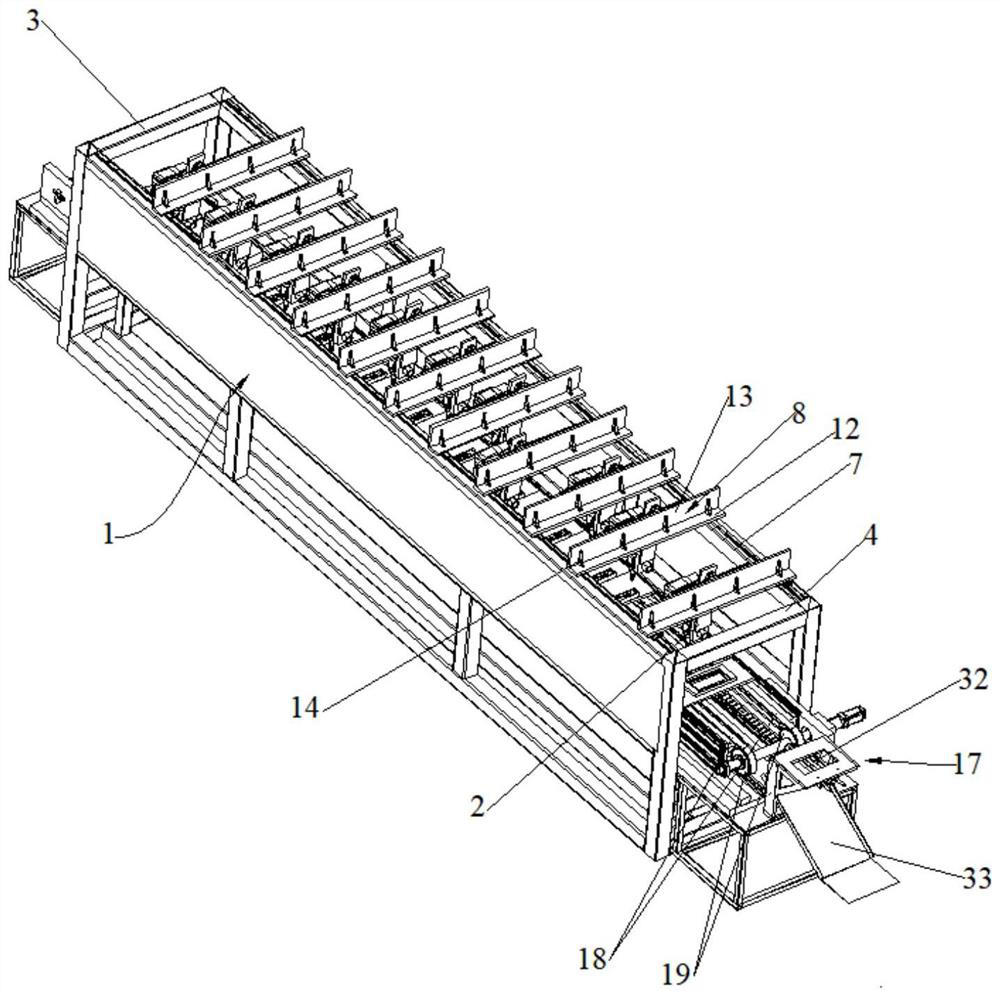

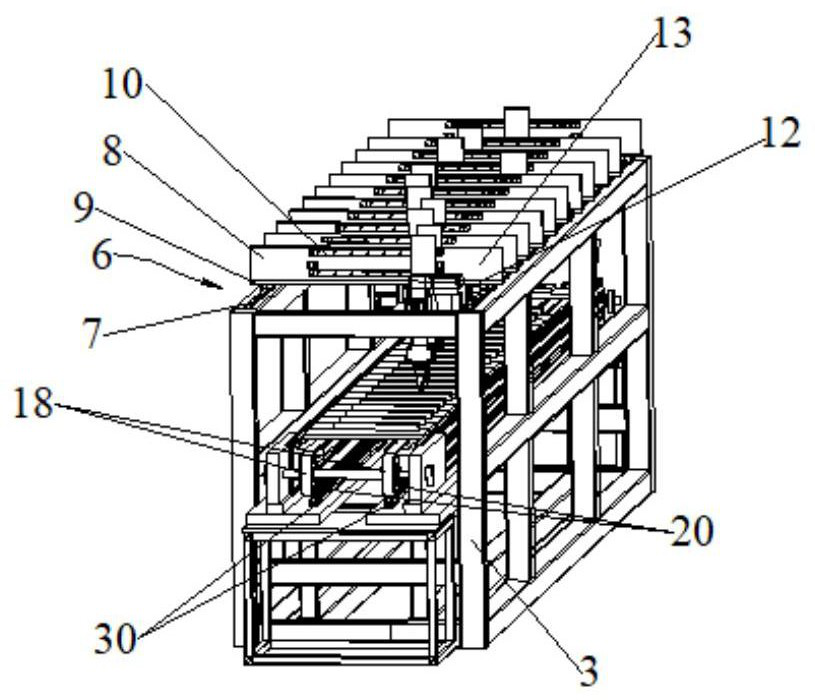

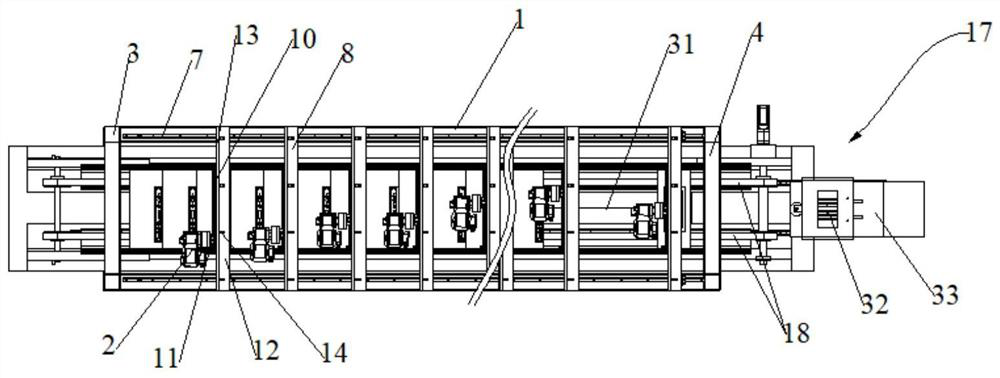

[0048] Such as Figure 1-3 Shown, be the embodiment of multi-station drilling production line of the present invention, comprise frame 1, be arranged on several drilling machines 2 of different stations on described frame 1 respectively, be arranged on described frame 1 There is a conveying mechanism 5 with a feeding end 3 and a feeding end 4, and a drill bit that is arranged on the frame 1 to support the drilling machine 2 on each station and carries the drilling machine 2 Adjust the adjustment mechanism 6 to the desired position.

[0049] In the adjustment mechanism 6, there are respectively a longitudinal slide rail 7 laid on the frame 1 along the workpiece conveying direction on both sides of the workpiece conveying path, corresponding to each of the drilling machines 2 having a vertical The transverse arm 8 extending in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com