Building assembly hoisting device and construction method thereof

A technology of hoisting device and gantry, which is applied in the directions of hoisting device, transportation and packaging, load hanging components, etc., can solve the problems of difficult building assembly space, inconvenient construction, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The present invention provides a technical solution: a building assembly hoisting device, comprising:

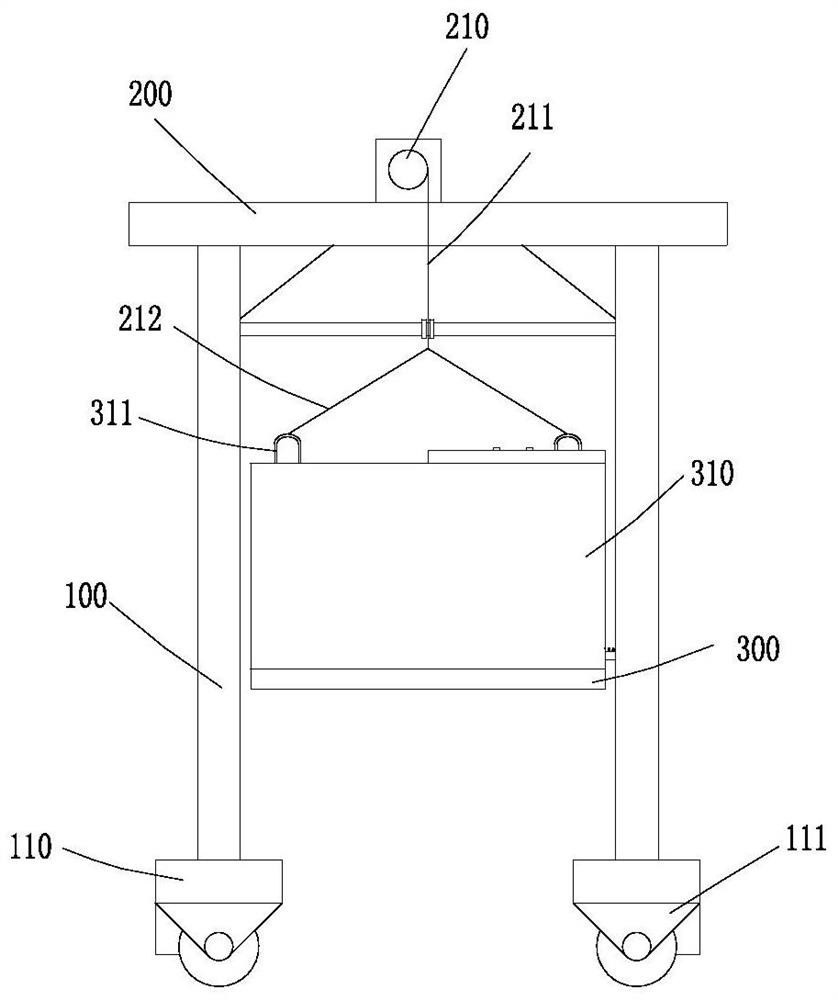

[0039] The portal frame 100 is provided with a crossbeam 200 on the top of the portal frame 100. Two groups of hoists 210 are installed on the top of the portal frame 100. , the first traction rope 211 is connected with two sets of second traction ropes 212;

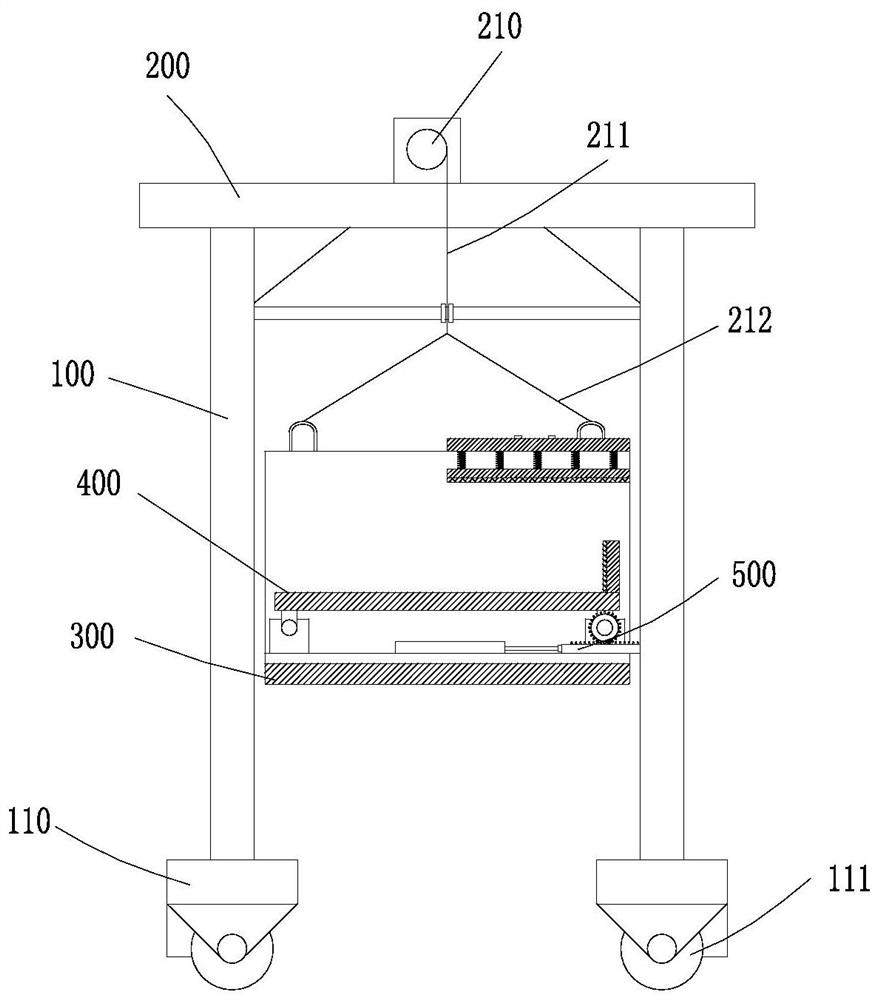

[0040] Lifting plate 300, the front side and rear side of lifting plate 300 are respectively provided with vertical boards 310, and the upper end of each group of vertical boards 310 is provided with two sets of fixing rings 311, and the fixing rings 311 are connected with the second traction rope 212;

[0041] The material receiving plate 400, the material receiving plate 400 is arranged above the lifting plate 300 for placing the construction assembly, and the lower end of the material receiving plate 400 is provided with a driving assembly 500 for tilting and lifting the building assembly on the material rece...

Embodiment 2

[0044] On the basis of embodiment 1,

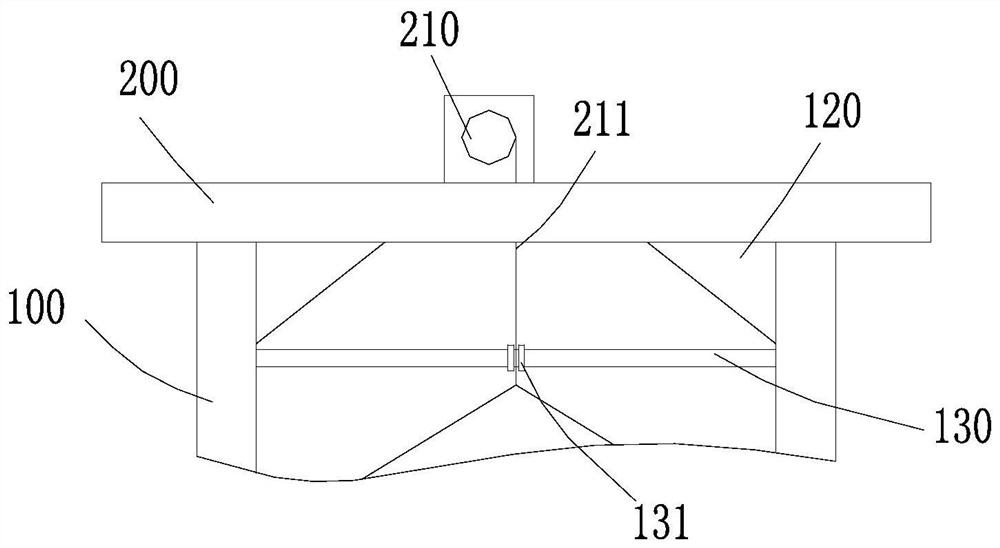

[0045]The bottom of the door frame 100 is provided with a fixed base 110 , and the lower end of the fixed base 110 is equipped with a moving wheel set 111 . Ribs 120 are arranged inside the door frame 100 , and the ribs 120 extend obliquely upwards and are connected with the beams 200 . The door frame 100 is provided with a fixed plate 130 under the crossbeam 200 , the front side and the rear side of the fixed plate 130 are respectively provided with guide wheels 131 , and the first traction rope 211 is slidingly connected with the guide wheels 131 .

[0046] Specifically, the hoisting device adjusts the position through the moving wheels to meet the hoisting requirements, and improves the mechanical structural strength of the beam 200 through the set ribs 120, and the four sets of first traction ropes 211 are in line with the guide wheels 131 when they move. Sliding connection, stable movement stroke, not easy to shake, stable movement ...

Embodiment 3

[0048] On the basis of Embodiment 1 or Embodiment 2, the drive assembly 500 includes two sets of guide rails 510 arranged at intervals on the upper end of the lifting plate 300, and the inner sides of each set of guide rails 510 are respectively provided with a first support platform 520 and a second support platform 530 at intervals, The upper end of the first support platform 520 is provided with an arc-shaped groove 521, the second support platform 530 is provided with a bearing assembly 531, and the lower end of the material receiving plate 400 is provided with a first round rod 540 and a second round rod 550 at intervals. 540 is engaged in the arc-shaped groove 521, the second round rod 550 is movably installed in the bearing assembly 531, and the two ends of the second round rod 550 are provided with rotating gears 551; , the upper end of the moving plate 560 is provided with a toothed plate 561, and the rotating gear 551 is meshed with the gear. The lifting plate 300 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap