Inker cam device capable of freely ascending, descending and moving leftwards and rightwards

A technology of settlement triangle and left and right movement, applied in textiles and papermaking, knitting, weft knitting and other directions, can solve the problems of inability to move up and down, easy to break yarns, affecting the quality of fabrics, etc., to improve the probability of success, not easy to break, reduce The effect of purchasing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0026] Example.

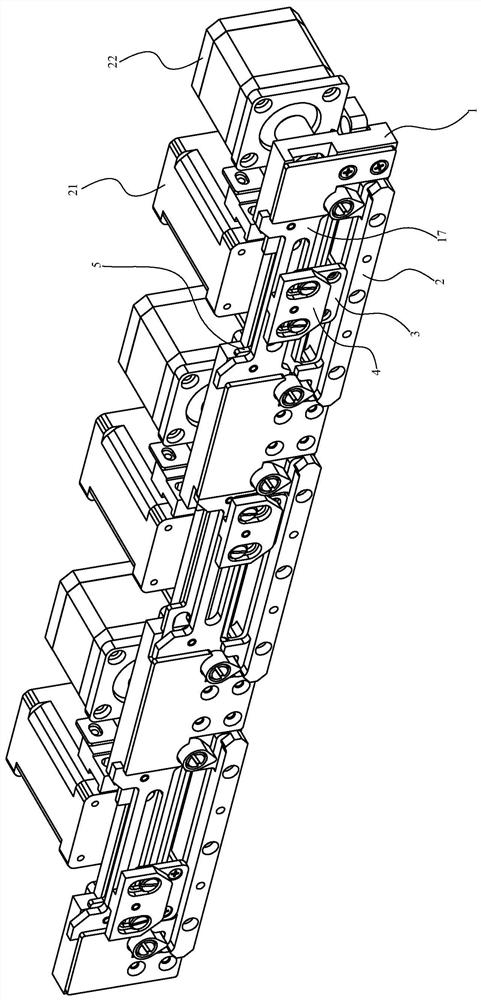

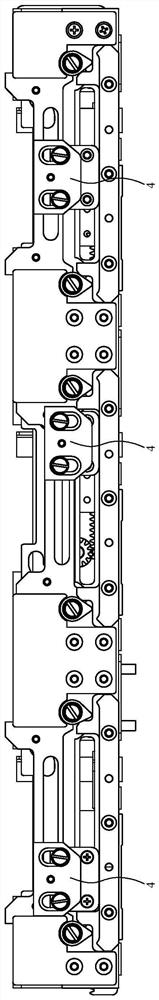

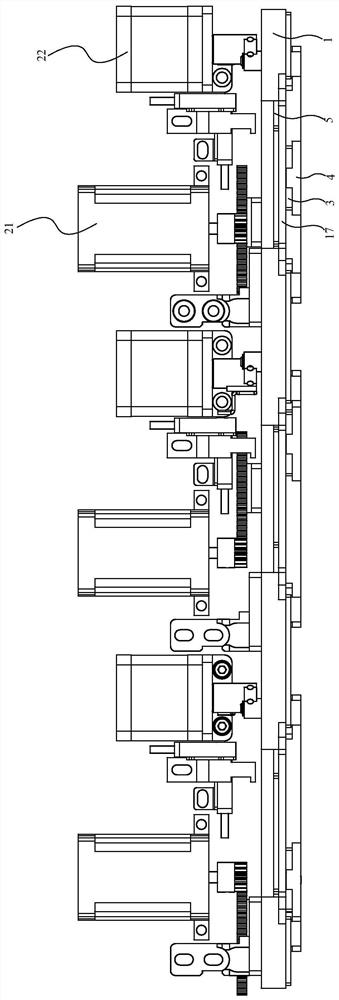

[0027] see Figure 1 to Figure 4 .

[0028] This embodiment discloses a sinking cam device that can freely move up and down, left and right. This sinking cam mechanism is used in conjunction with a normally closed sinker (refer to the prior art), which can effectively reduce the current domestic two-needle plate garment machine technology. Difficulty requirements greatly increase the success rate of the two-needle board and one-line garment machine.

[0029] The settling cam device includes a base plate 1, a settling cam 4, a guide plate 3, a pull plate 5, a lifting slider 17, a drive mechanism No. 1 and a drive mechanism No. 2, wherein the settling cam 4, the guide plate 3, the draw plate 5, Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com