Drainage pipe network monitoring point distribution method suitable for defective pipeline troubleshooting

A drainage pipe network and pipeline technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of unrealistic, high cost of water quality and water quantity sensor equipment and high labor operation and maintenance costs, to avoid blindness, Improve utility value, adapt to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

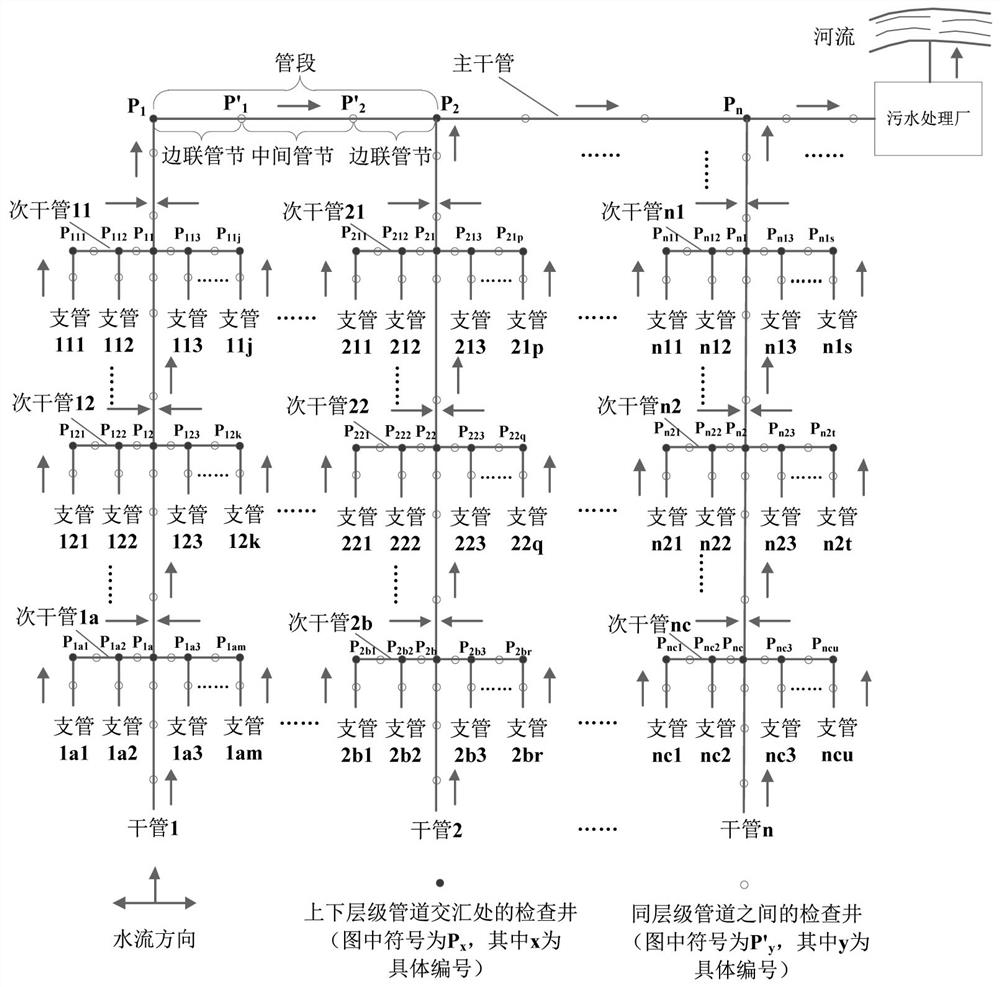

[0031] Such as Figure 1 to Figure 6 Among them, a drainage pipe network monitoring and distribution method suitable for defect pipeline investigation, it includes the following steps:

[0032] Step 1, topology, analyze the topology structure of the pipe network in the target area, and divide the pipe level, pipe section and pipe joint of the pipe network;

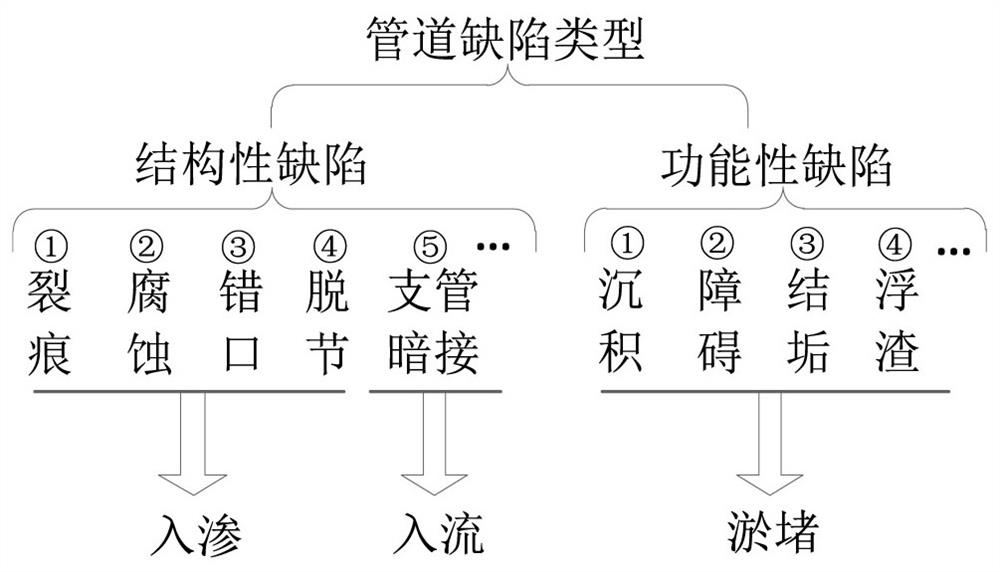

[0033] Step 2, analyze, compare and analyze the detection data of the flow sensor, and obtain the mapping relationship between the flow sensor and the pipeline defect situation;

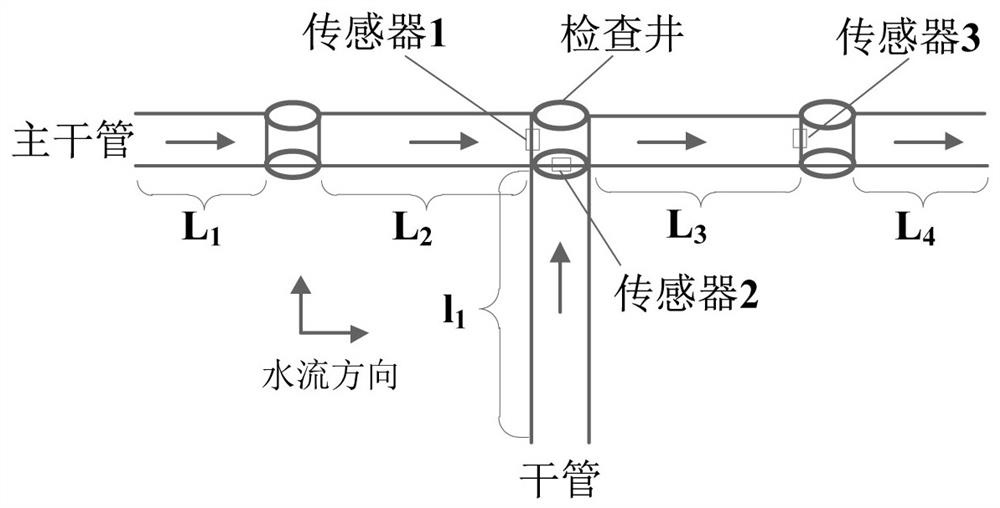

[0034] Step 3, setting, setting the applicability of the arrangement of "straight line" and "hook" sensor groups;

[0035] Step 4, laying out, first laying out the "hook" sensor group in the unit of pipe section, and then laying out the "linear" sensor group for the pipe joints in the pipe section. In this step, according to the principle of "the length of the pipeline that enables the sensor group to achieve accurate judgment is the largest, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com