Intelligent compression fatigue testing device based on automation

A fatigue testing and intelligent technology, applied in the field of fatigue testing, can solve the problems of time-consuming and labor-intensive, few anti-fatigue testing devices, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

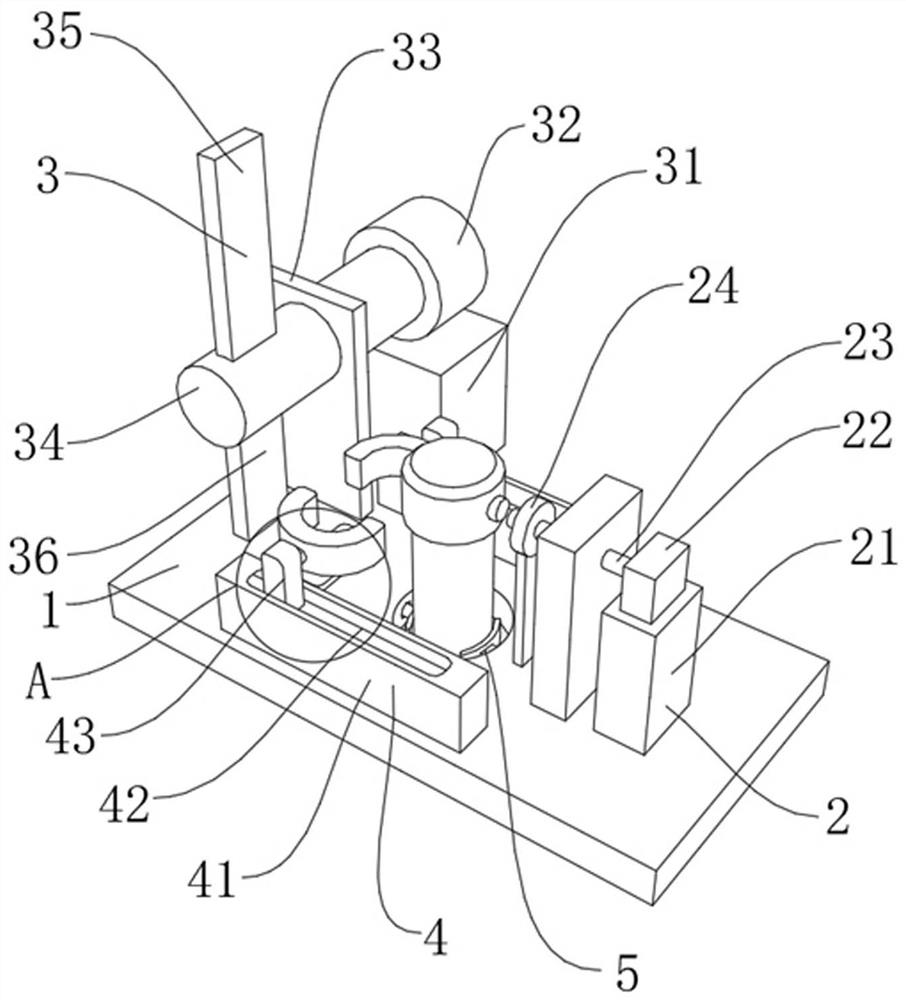

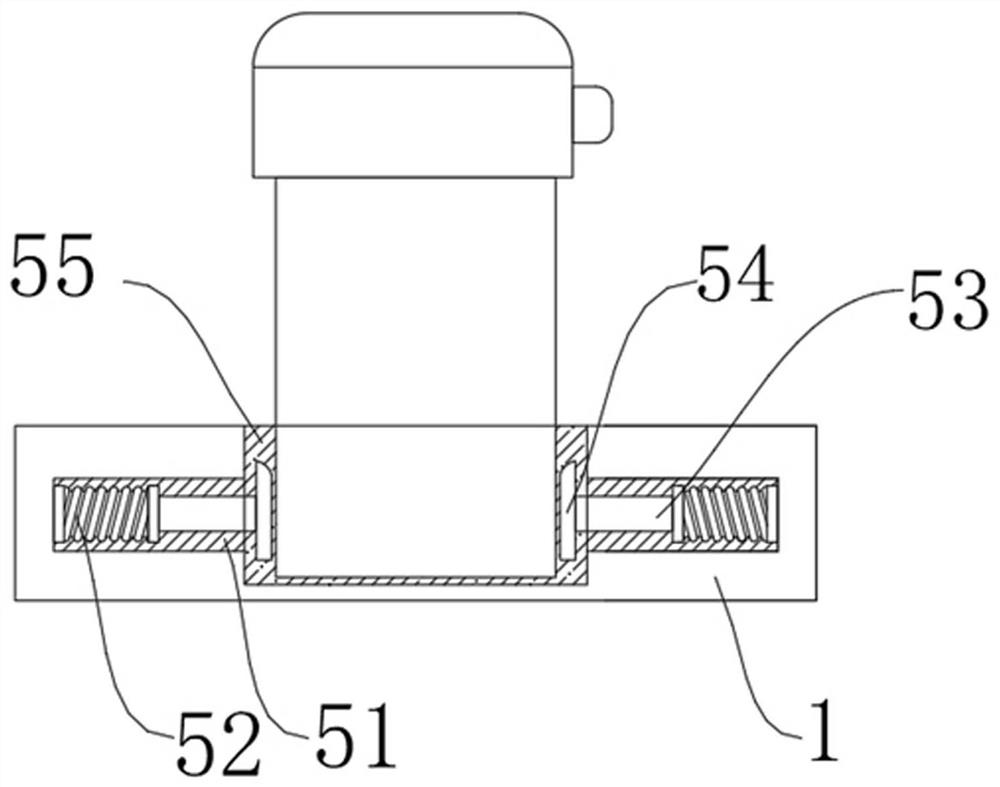

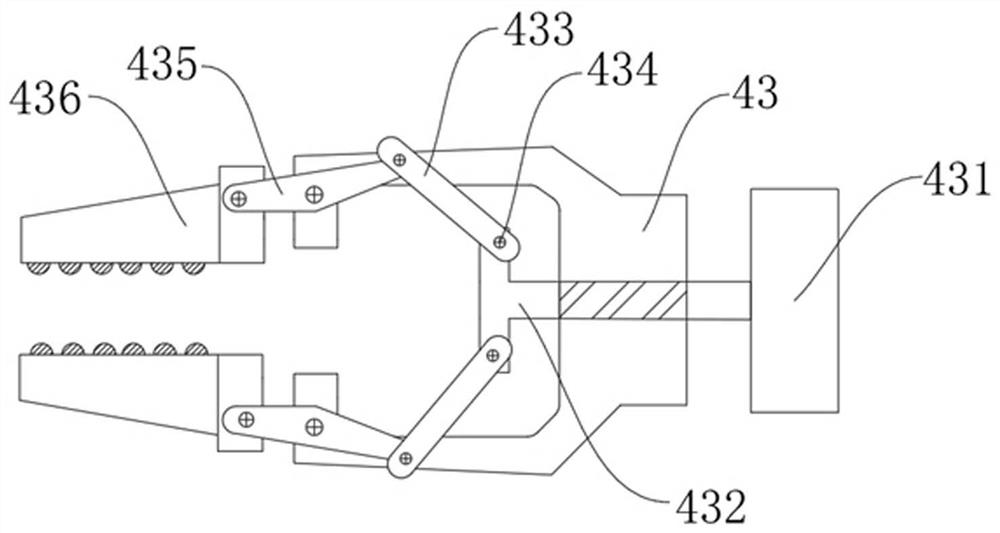

[0031] see Figure 1-Figure 4 As shown, based on the automated intelligent anti-compression fatigue test device, it is applied to the anti-fatigue test of the water leakage of the thermos cup. In some embodiments, it includes a fixed platform 1. The fixed platform 1 can be a fixed shape plate with a certain thickness and width. It can also be the operating platform of the operating machine platform, and in specific implementation, the fixed platform 1 is not limited.

[0032] One end of the fixed table 1 is provided with a closing assembly 3, and the other end is provided with a touch assembly 2. Here, one end is only one end in the length direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com