Injection molding machine energy consumption abnormity detection method and system based on Gaussian mixture model

A Gaussian mixture model and anomaly detection technology, applied in computer-related fields, can solve problems such as high false alarm rate, low detection accuracy, and inaccurate multi-dimensional data classification, and achieve the effect of improving anomaly detection accuracy and reducing false alarm rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

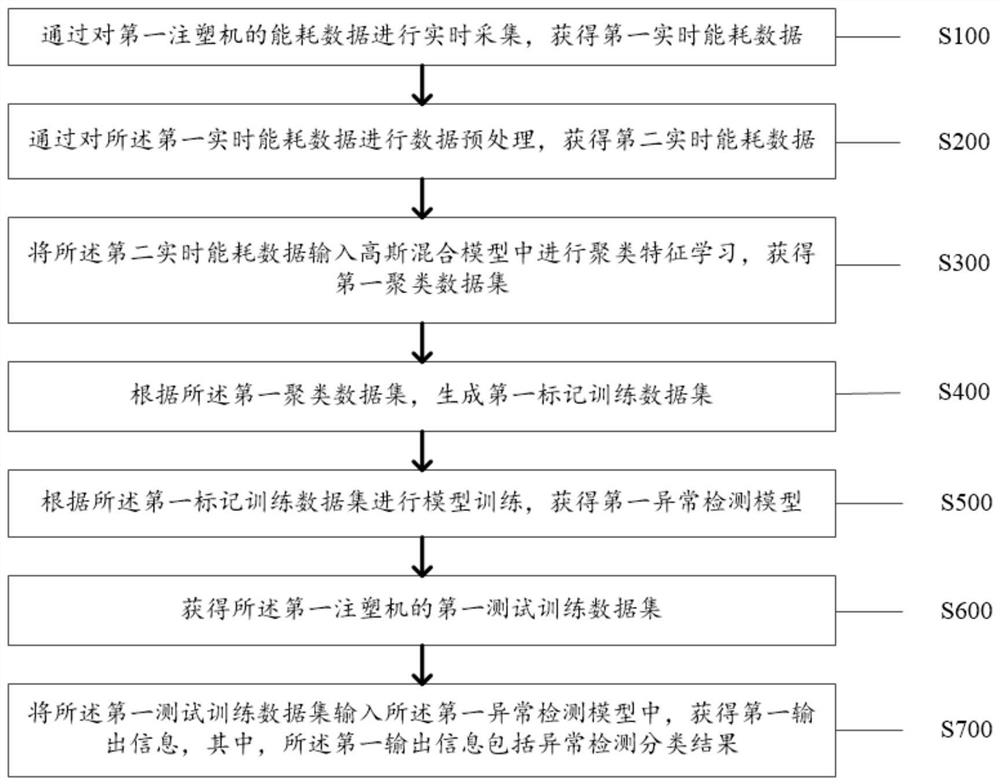

[0027] like figure 1 As shown, the embodiment of the present application provides a method for detecting abnormal energy consumption of an injection molding machine based on a Gaussian mixture model, and the method includes:

[0028] Step S100: Obtain first real-time energy consumption data by collecting energy consumption data of the first injection molding machine in real time;

[0029] Step S200: Obtain second real-time energy consumption data by performing data preprocessing on the first real-time energy consumption data;

[0030] Specifically, real-time data collection of injection molding machines is carried out under certain environmental conditions. The process of data collection can also be completed by communicating with the database of an injection molding machine manufacturer’s energy management system. The data also needs to collect the data of the factors affecting the production energy consumption of the injection molding machine. Further, the accumulated data...

Embodiment 2

[0087] Based on the same inventive concept as the Gaussian mixture model-based method for detecting abnormal energy consumption of injection molding machines in the foregoing embodiments, the present invention also provides a system for detecting abnormal energy consumption of injection molding machines based on Gaussian mixture models, such as Figure 5 As shown, the system includes:

[0088] A first obtaining unit 11, configured to obtain first real-time energy consumption data by collecting the energy consumption data of the first injection molding machine in real time;

[0089] A second obtaining unit 12, configured to obtain second real-time energy consumption data by performing data preprocessing on the first real-time energy consumption data;

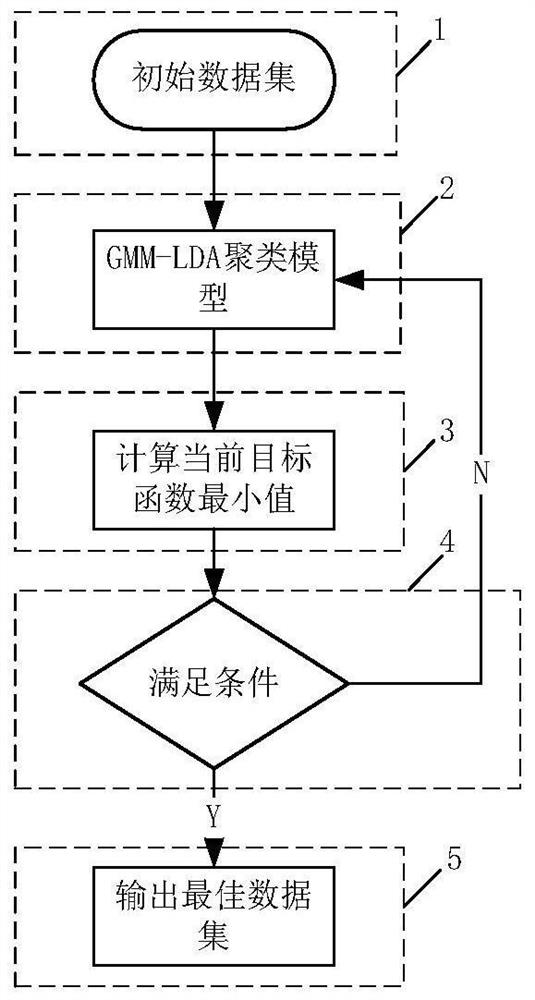

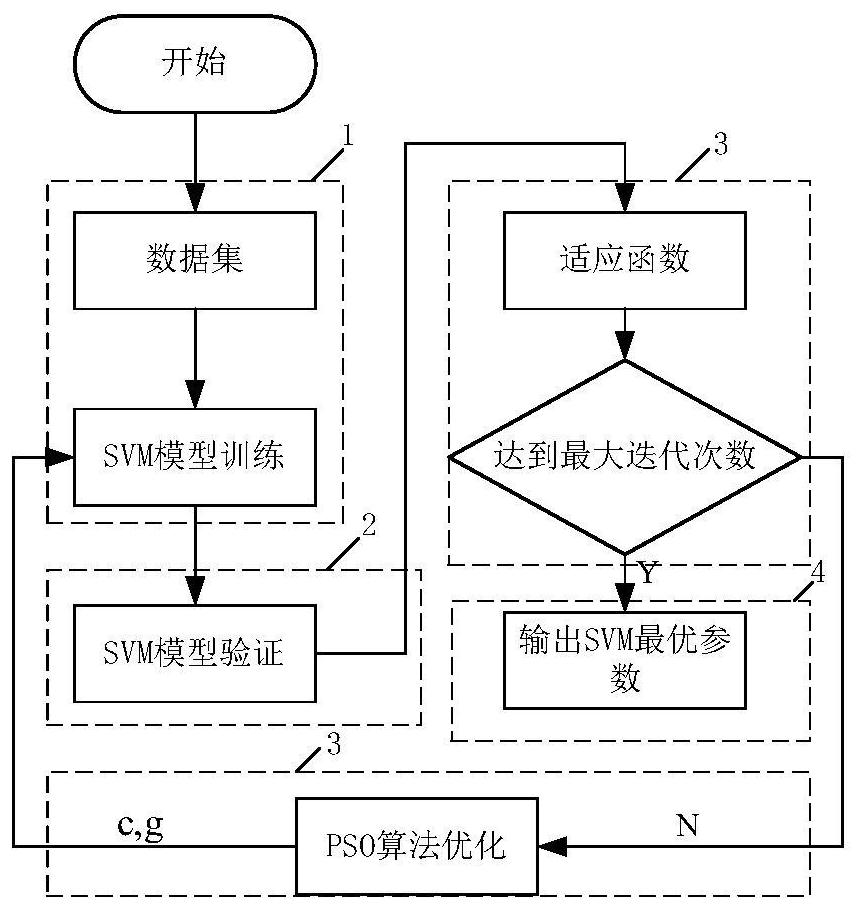

[0090] A first input unit 13, configured to input the second real-time energy consumption data into a Gaussian mixture model for cluster feature learning to obtain a first cluster data set;

[0091] A first generating unit 14, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com