Acoustic drainage structures and electronics

A technology of drainage structure and electronic equipment, applied in the field of acoustics, can solve the problems of low microphone loudness, hinder the sound conduction of waterproof membrane, affect the sound pickup quality of the microphone, etc., and achieve the effect of improving the sound pickup quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

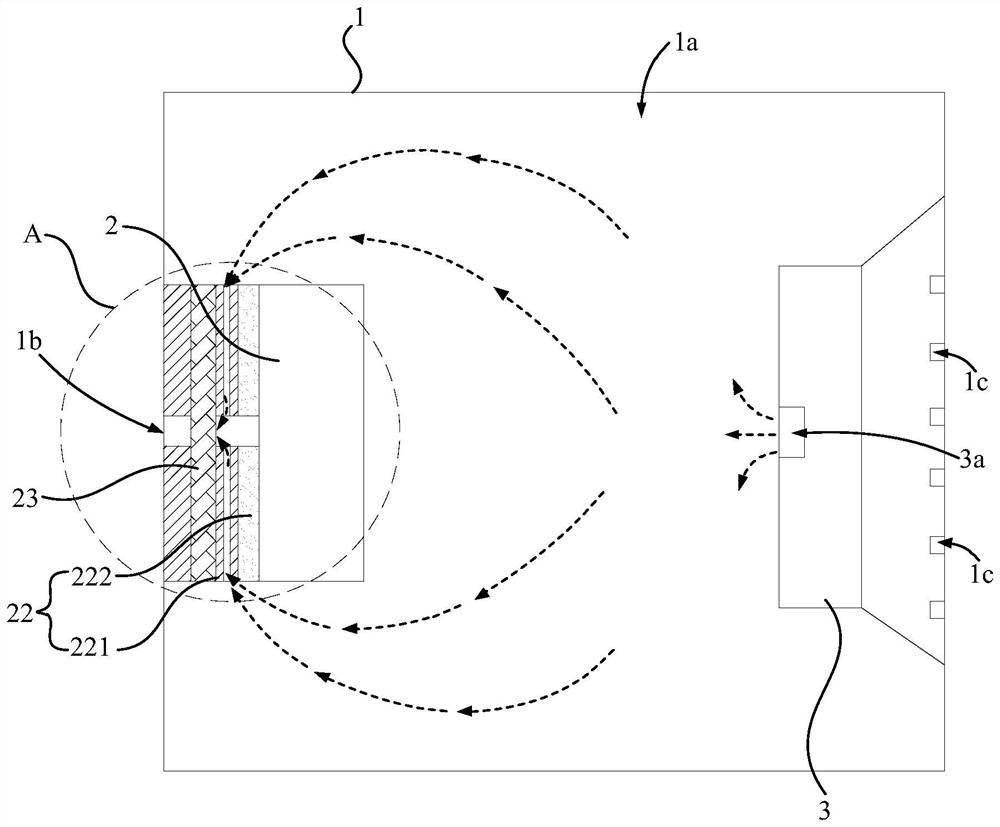

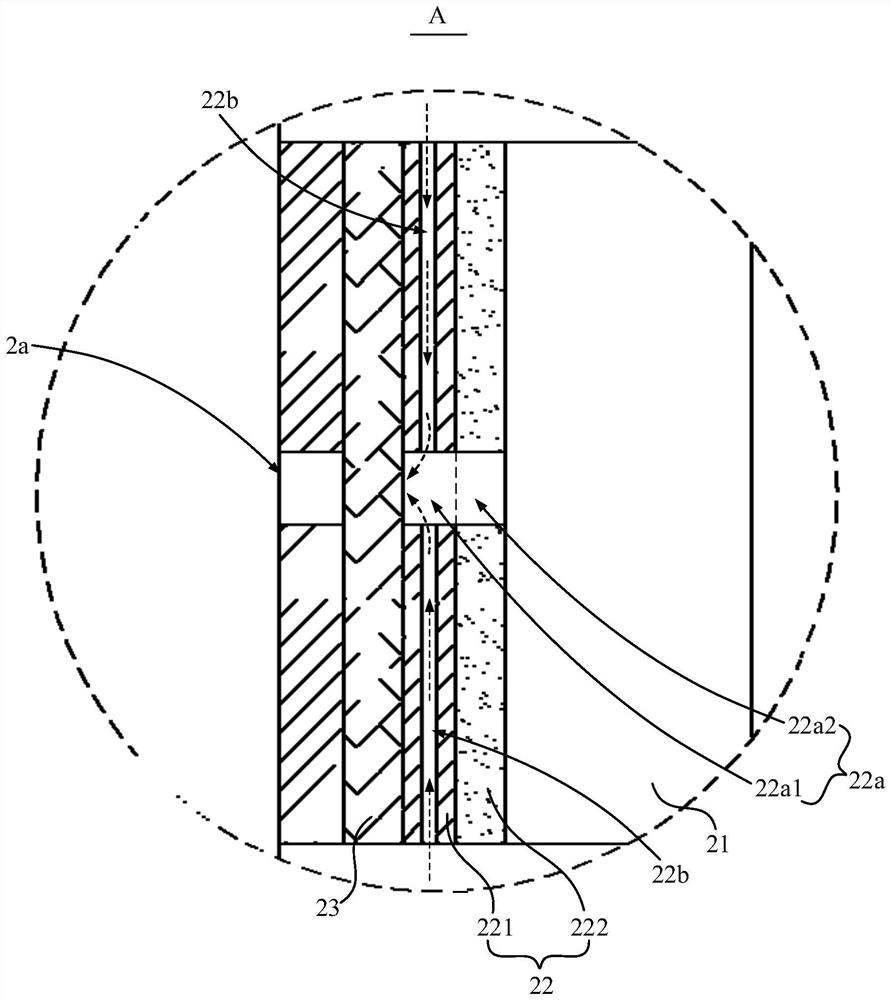

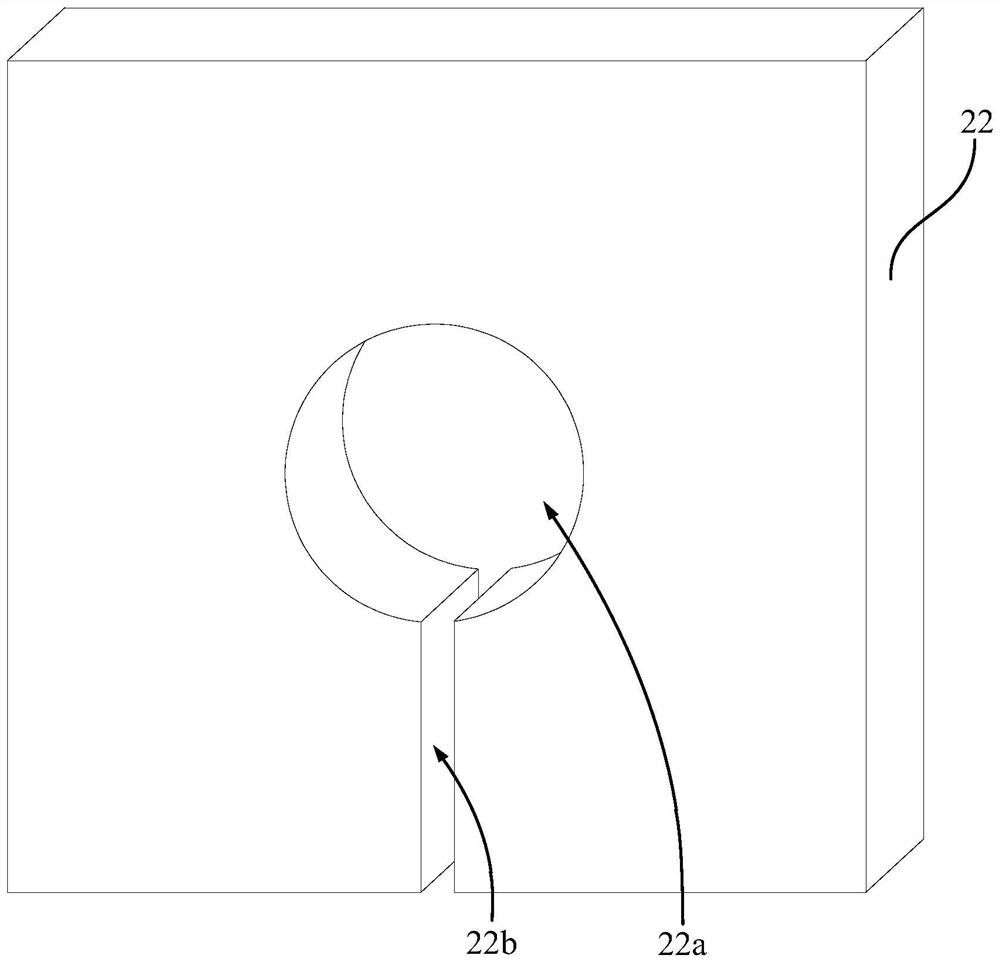

[0061] See 3, and combine figure 1 and figure 2 As shown, the air guide channel 22b passes through the outer wall of the connecting piece 22 and the hole wall of the second sound collecting hole 22a.

[0062] In this embodiment, the number of the air guide passages 22b is one, the air guide passage 22b is a single-channel structure connecting the pickup cavity 2a and the cavity 1a, and the shape of the air guide passage 22b includes, but is not limited to, a straight line, an arc shape , wave shape, at this time, the air vibration in the cavity 1a will cause the air vibration in the pickup cavity 2a through a single air guide channel 22b, and then drive the breathable waterproof membrane 23 to vibrate to realize the drainage of the breathable waterproof membrane 23. Because only one ventilation channel is opened on the connector 22, the processing procedure of the connector 22 can be reduced as much as possible on the premise of realizing the drainage function of the pickup ...

no. 2 example

[0064] see Figure 4 , and combine figure 1 and figure 2 As shown, the air guide passage 22b includes at least two air guide branches 22b1 provided on the connector 22, at least two air guide branches 22b1 are connected to each other, and at least one air guide branch 22b1 is connected to the pickup cavity 2a and the cavity 1a .

[0065] In this embodiment, the air guide channel 22b may include two or more air guide branches 22b1, wherein the two air guide branches 22b1 or the multiple air guide branches 22b1 are directly connected. For example, as Figure 4 As shown, the air guide channel 22b includes four air guide branches 22b1, and the four air guide branches 22b1 are arranged on the upper and lower sides of the second sound pickup hole 22a, and are located on two sides of the same side of the second sound pickup hole 22a. The air guide branches 22b1 communicate with each other, and the air guide branches 22b1 located on different sides of the second sound pickup hole...

no. 3 example

[0068] see Figure 5 , and combine figure 1 and figure 2 As shown, the air guide passage 22b further includes at least one communication branch 22b2, and each communication branch 22b2 communicates with two air guide branches 22b1.

[0069] In this embodiment, different from the solution of the second embodiment, some of the air guide branches 22b1 communicate with each other through the communication branch 22b2 instead of directly communicating with each other. The design that the air guide branches 22b1 are communicated through the communication branch 22b2 improves the air circulation between the air guide branches 22b1 and the air content in the air guide channel 22b, which is beneficial when the air in the air guide channel 22b vibrates. , the air in the second sound pickup hole 22a exerts a stronger driving force on the breathable waterproof membrane 23, drives the breathable waterproof membrane 23 to generate a larger vibration, and improves the shaking strength of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com