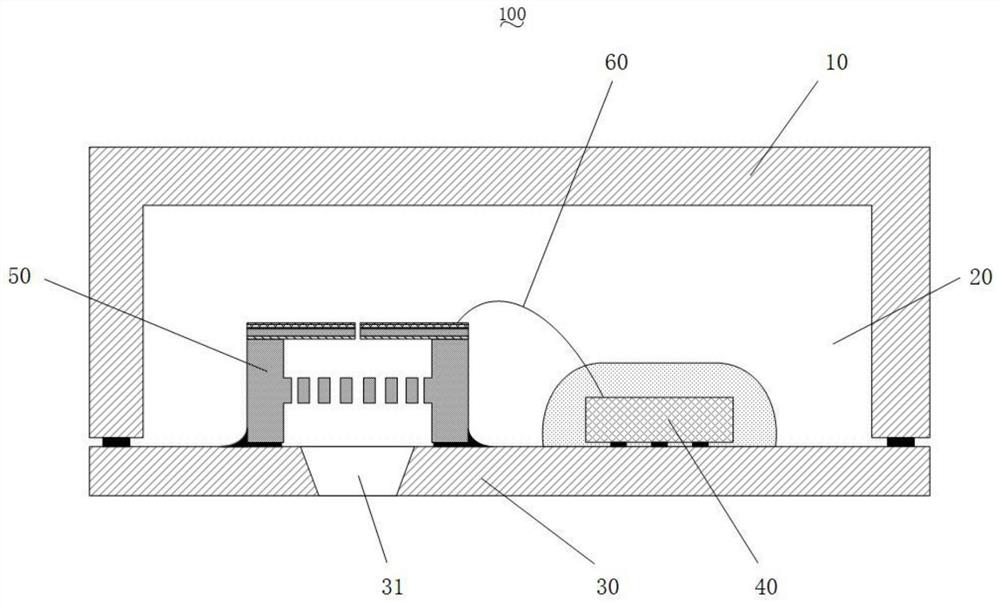

A piezoelectric acoustic transducer with filtering function and its manufacturing method

An acoustic transducer and piezoelectric technology, applied in piezoelectric/electrostrictive transducer microphones, microphones, sensors, etc., can solve the problems of poor sound pickup effect and improve the sound pickup quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

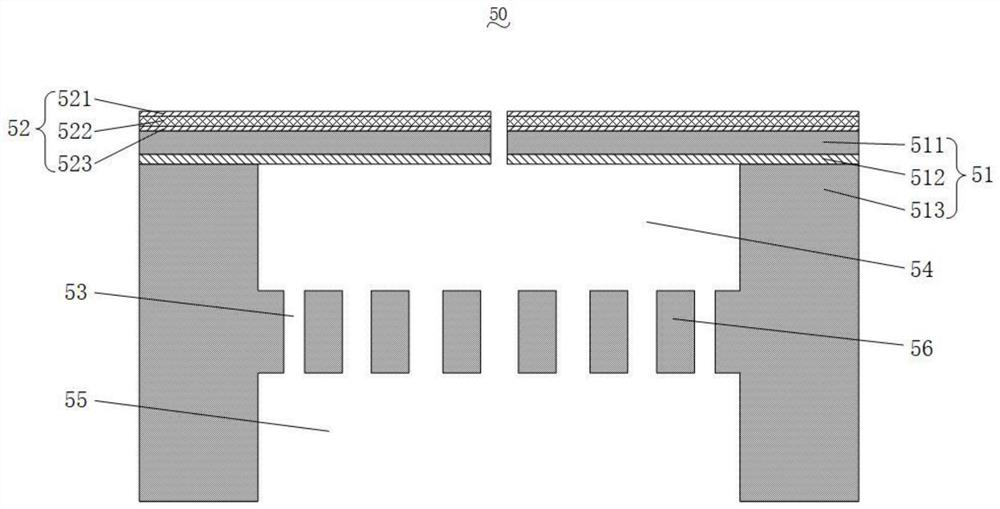

[0048] Embodiment 1 provides a piezoelectric acoustic transducer with filtering effect, see Figure 9 , the diaphragm 52 adopts a cantilever beam structure with a fixed center, and the center fixed end of the diaphragm 52 is established on the filter layer 56 .

[0049] The filter layer 56 includes a support column 57 , the support column 57 serves as a support for the diaphragm 52 , and the filter layer 56 defines the through hole 53 in a region outside the support column 57 . The diaphragm 52 can be divided into a plurality of diaphragms.

Embodiment 2

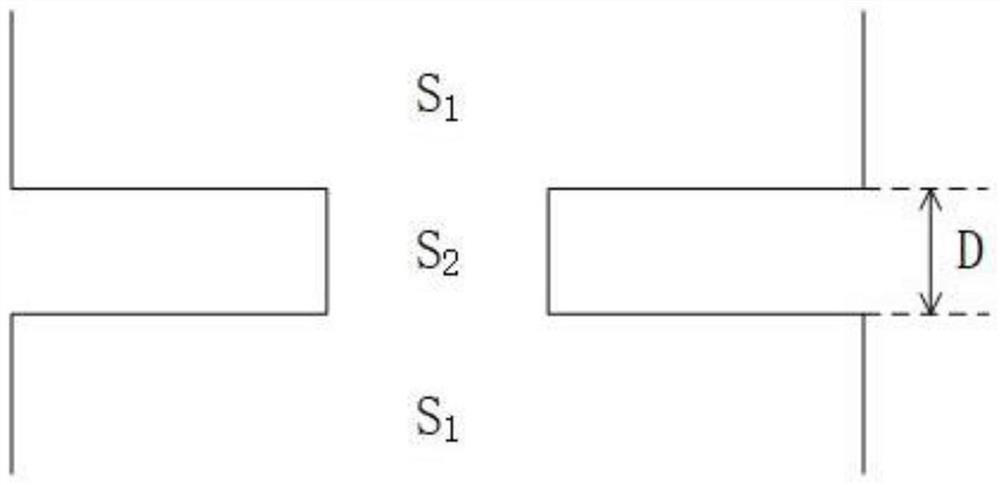

[0051] The diaphragm 52 adopts a cantilever beam structure with an outer periphery fixed, and the outer periphery fixed end of the diaphragm 52 is established on the substrate 51, such as image 3 shown. The diaphragm 52 can be divided into a plurality of diaphragms.

Embodiment 3

[0053] Embodiment 3 provides a method for manufacturing a piezoelectric acoustic transducer with filtering effect as described in Embodiment 1 or Embodiment 2, specifically a method for manufacturing a MEMS chip, including the following steps:

[0054] Step 1. Select a silicon wafer as the first insulating layer 513, and form a cavity structure on the silicon wafer through photolithography and etching processes;

[0055] Step 2, deposit silicon dioxide 541 in the cavity structure, and use chemical mechanical polishing process to grind the surface flat; see Figure 5 (corresponding to embodiment 2), Figure 11 (corresponding to embodiment 1);

[0056] Step 3, bonding a composite layer consisting of a transition layer 512 and a second insulating layer 511 on the silicon wafer with the cavity structure;

[0057] Step 4. Deposit materials in sequence on the composite layer to form a structural layer, and the structural layer is used as the diaphragm 52; see Image 6 (correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com