Pressurizing device for tire vulcanizing machine

A technology for pressurizing device and tire vulcanization, applied in the field of pressurizing device, can solve the problems of low mold clamping accuracy, high initial cost and maintenance cost, uneven mold clamping force, etc., to achieve outstanding economic performance, reduce procurement costs and use Cost, clamping pressure uniform and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0039] In order to realize the purpose of the present invention, the technical scheme provided by the present invention is:

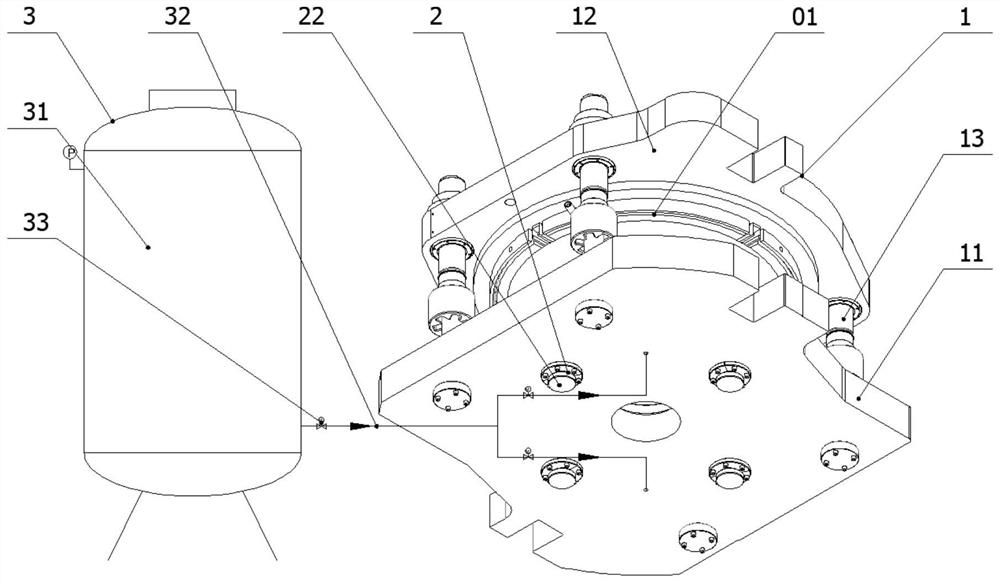

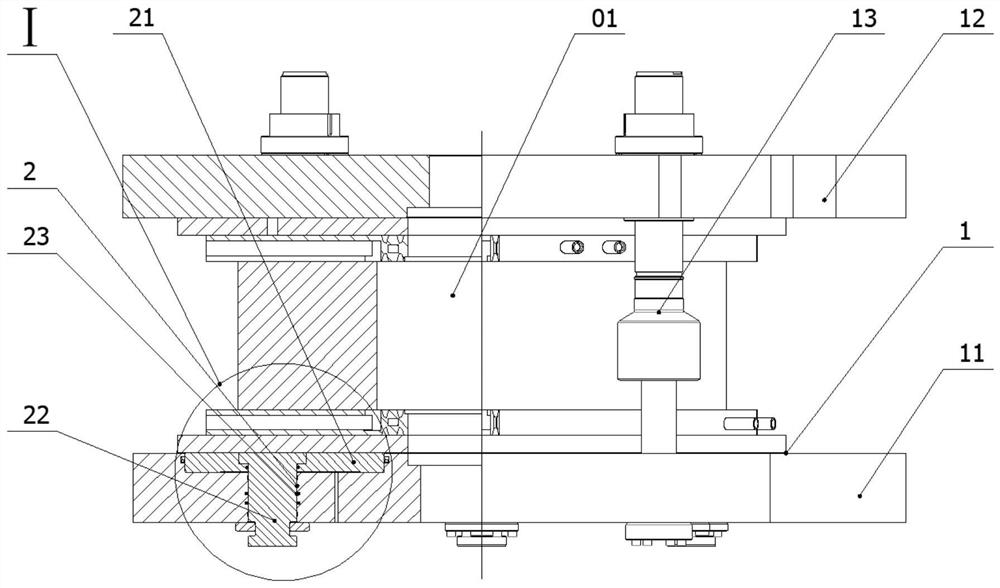

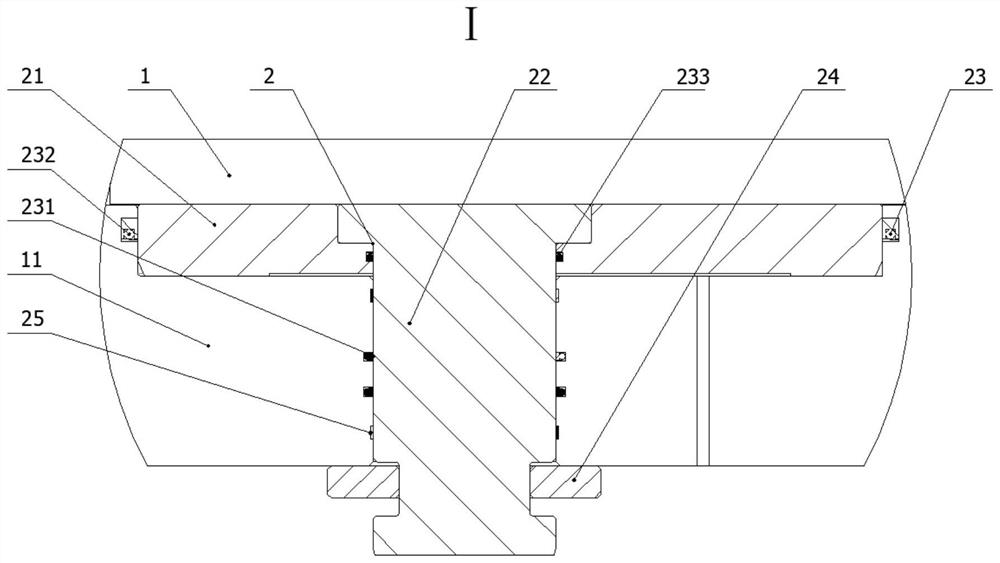

[0040] In some embodiments, such as Figure 1-3As shown, a pressurizing device for a tire vulcanizing machine is used for pressurizing the mold 01, including: a pressurizing frame 1, a frame structure that provides pressure for the mold 01, including a bottom plate 11, a top plate 12 and a tie rod 13, and the bottom plate 11 and the top plate 12 are respectively located belo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap