Generator rotor cooling structure and use method thereof

A technology of generator rotor and cooling structure, applied in the shape/pattern/structure of magnetic circuit, shape/pattern/structure of winding conductor, rotating parts of magnetic circuit, etc., can solve the complex manufacturing process of rotor coil and the heat transfer path of coil It can improve the overall cooling effect, the cooling effect is good, and the cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

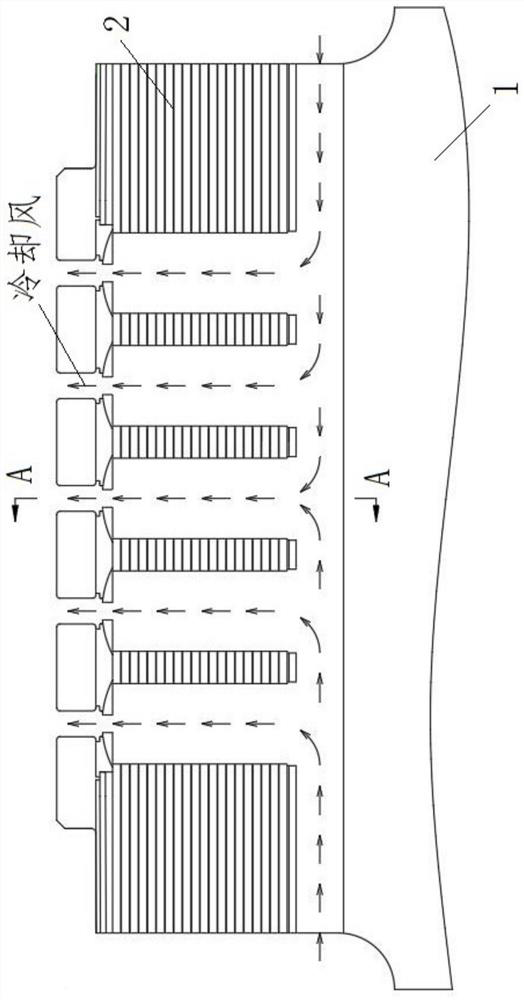

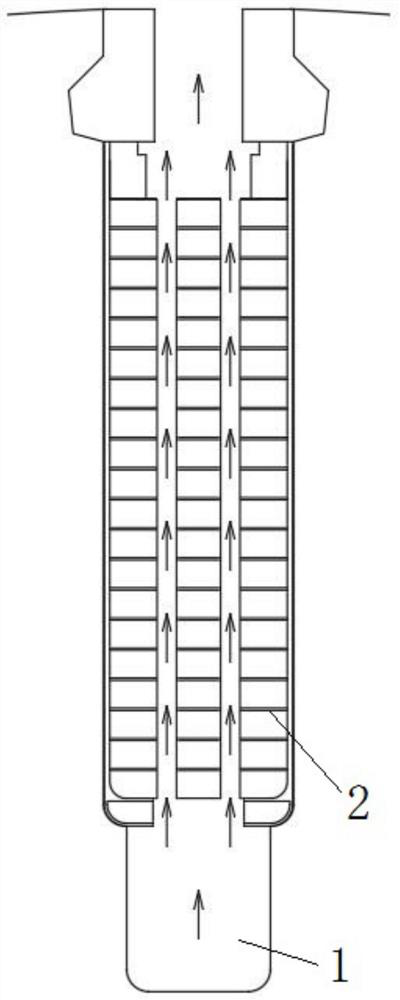

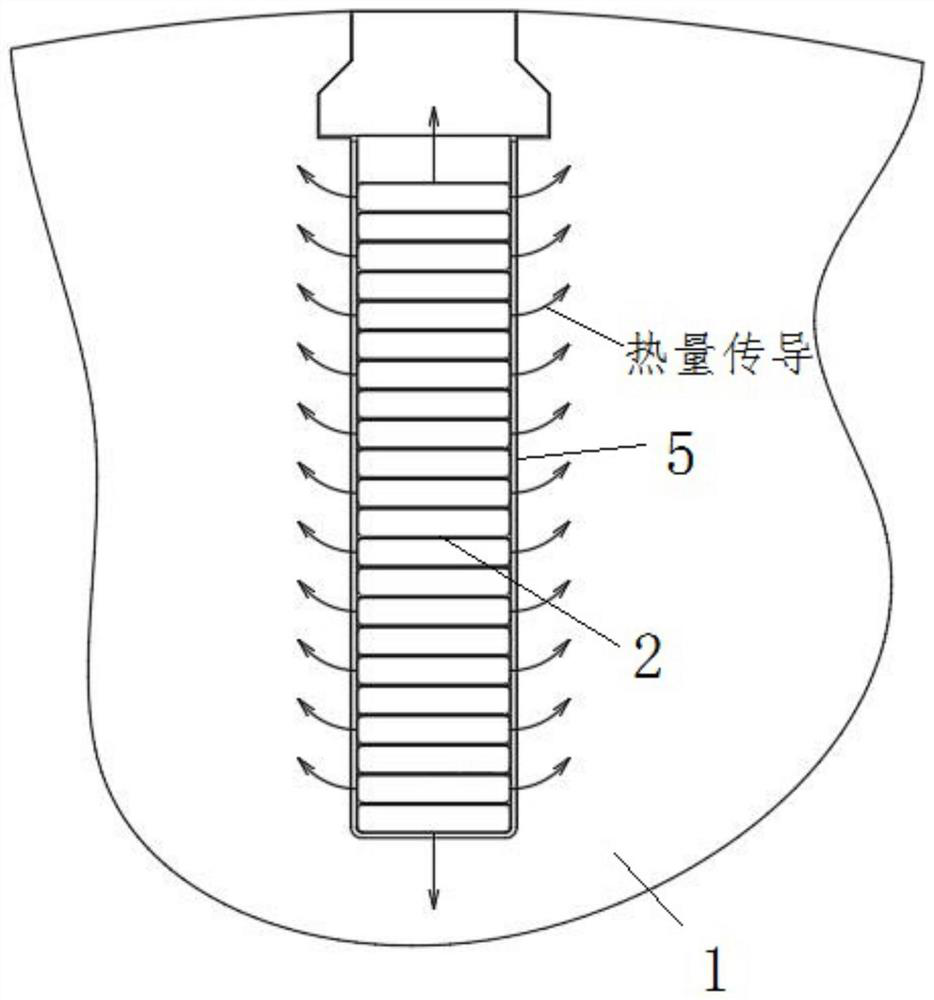

[0056] Such as Figure 1 to Figure 6 As shown, a generator rotor cooling structure includes a rotor body 1 and a rotor coil 2 wound on the outer surface of the rotor body 1. The end surface of the rotor body 1 is provided with a first slot 3 extending to the opposite end surface. , the side of the rotor body 1 is provided with a second slot 4 intersecting with the first slot 3 .

[0057] When the generator rotates, the cooling air enters from the first slot 3 on the end surface of the rotor body 1 and is discharged from the second slot 4 on the side of the rotor body 1 .

[0058] The invention combines the advantages of traditional internal cooling and external cooling. The lower coil of the rotor body 1 is directly cooled by the cooling air, and the cooling effect is better. The end face of the rotor body 1 and the side surface of the rotor body 1 are provided with a first slot 3 and a second slot 4 respectively, and the structure of the rotor coil 2 is exactly the same as t...

Embodiment 2

[0071] Such as Figure 1 to Figure 6 As shown, as a further optimization of Embodiment 1, this embodiment includes all the technical features of Embodiment 1. In addition, this embodiment also includes the following technical features:

[0072] As a preferred technical solution, the cavity of the first slot 3 extends to the axis of the rotor body 1 .

[0073] This makes the ventilation area of the first slot 3 larger, and also makes the ventilation depth of the rotor body 1 larger, further improving the ventilation volume and cooling effect.

[0074] As a preferred technical solution, the size of one end of the first slot 3 close to the center of the end surface of the rotor body 1 is smaller than the size of the end close to the edge of the rotor body 1 .

[0075] This makes the ventilation area near the end of the rotor coil 2 larger, which is more conducive to the heat dissipation of the rotor coil 2 .

[0076] As a preferred technical solution, it is characterized in t...

Embodiment 3

[0081] A method for using a generator rotor cooling structure according to the present invention includes the following steps:

[0082] S1, start the engine to rotate the generator;

[0083] S2 , the cooling air enters from the first slot 3 on the end surface of the rotor body 1 , and the cooling air is discharged from the second slot 4 on the side of the rotor body 1 .

[0084] When the generator rotates, the cooling air enters from the first slot 3 on the end surface of the rotor body 1 and is discharged from the second slot 4 on the side of the rotor body 1 .

[0085] The invention combines the advantages of traditional internal cooling and external cooling. The lower coil of the rotor body 1 is directly cooled by the cooling air, and the cooling effect is better. The end face of the rotor body 1 and the side surface of the rotor body 1 are provided with a first slot 3 and a second slot 4 respectively, and the structure of the rotor coil 2 is exactly the same as that of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com