Rolling type multi-gear cigarette sorting device and cigarette sorting method

A kind of sorting device, rolling-type technology, applied in the field of rolling-type multi-level cigarette sorting device, can solve the problems of inconsistent cigarettes, low efficiency, damage of cigarettes, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to better understand the purpose, structure and function of the present invention, a further detailed description of the present invention will be made below in conjunction with the accompanying drawings.

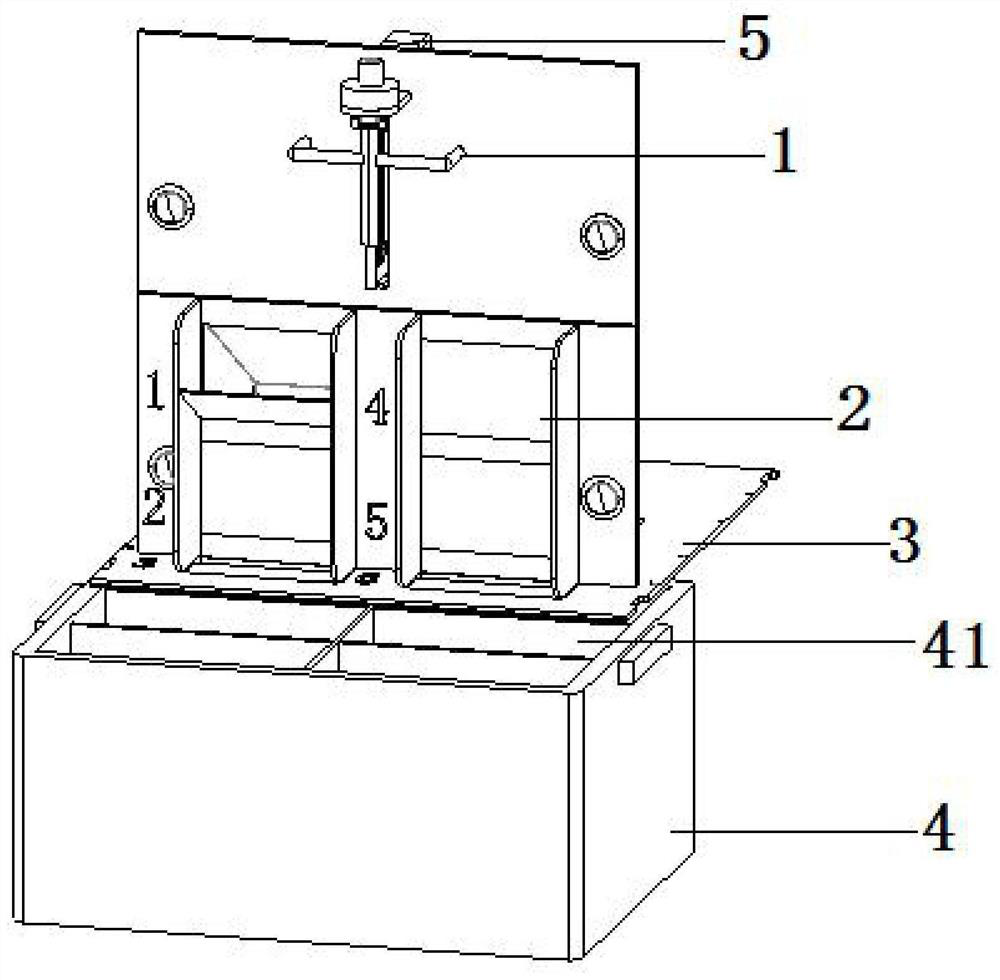

[0055] Such as figure 1 As shown, a roll-off multi-stage cigarette sorting device, the sorting device includes a cigarette picker 1, a screening panel 2, a partition panel 3 and a storage box 4;

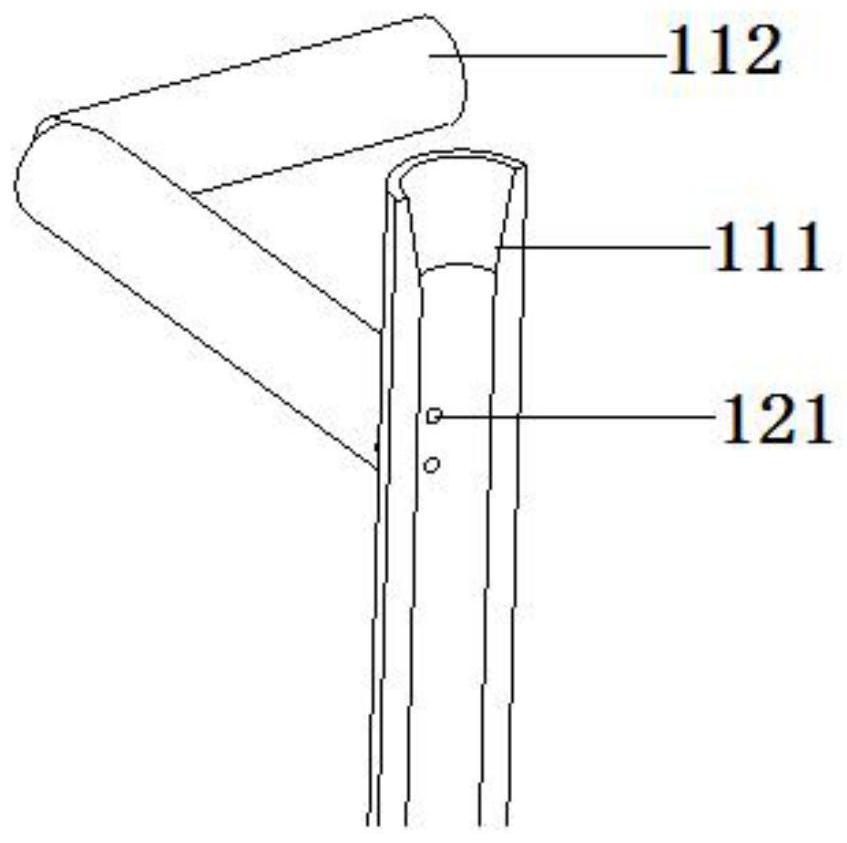

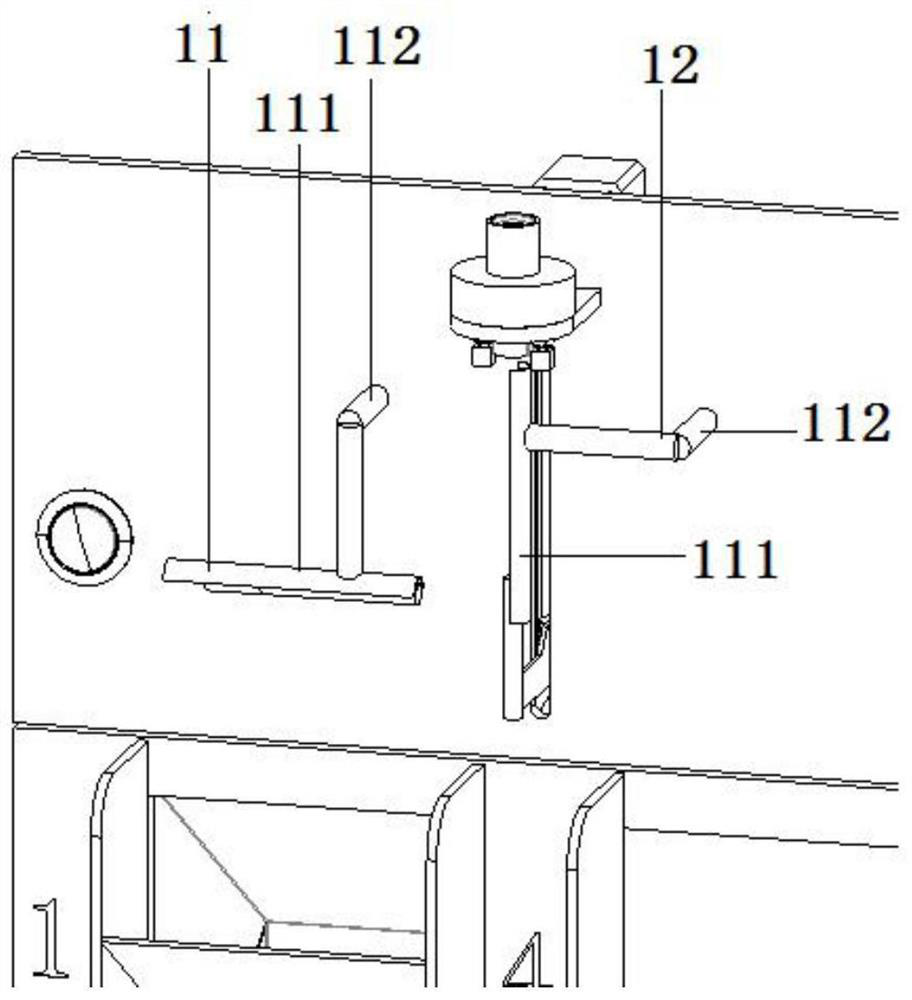

[0056] The cigarette picker 1 is arranged on the front end of the screening panel 2, and the cigarette picker 1 is composed of a left picker 11 and a right picker 12 which can rotate respectively, and one end of the left (right) picker It is a semi-tubular structure, and the other end is a tubular channel. A negative pressure adsorption hole 121 is opened inside the half tube. The half tube of the left picker 11 is spliced with the half tube of the right picker 12 to form a cigarette picker 1 Tubular channels running through both ends;

[0057] When loading cig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com