Radar cover shell replacement positioning detection method

A positioning detection and radome technology, which is applied to measuring devices, instruments, workpiece clamping devices, etc., can solve the problems of heavy process, unsatisfactory dimensional accuracy of the shell and supporting frame, and easy to make mistakes, and achieves accurate installation position. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below through specific embodiments.

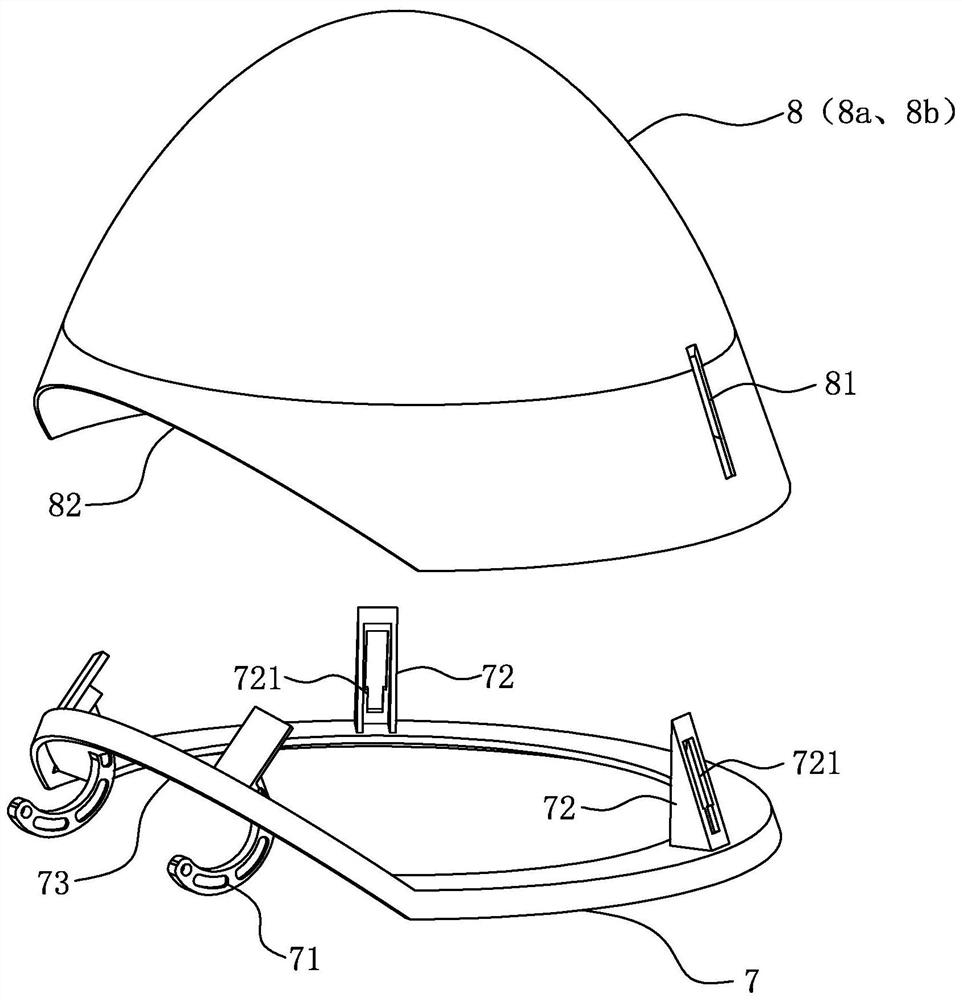

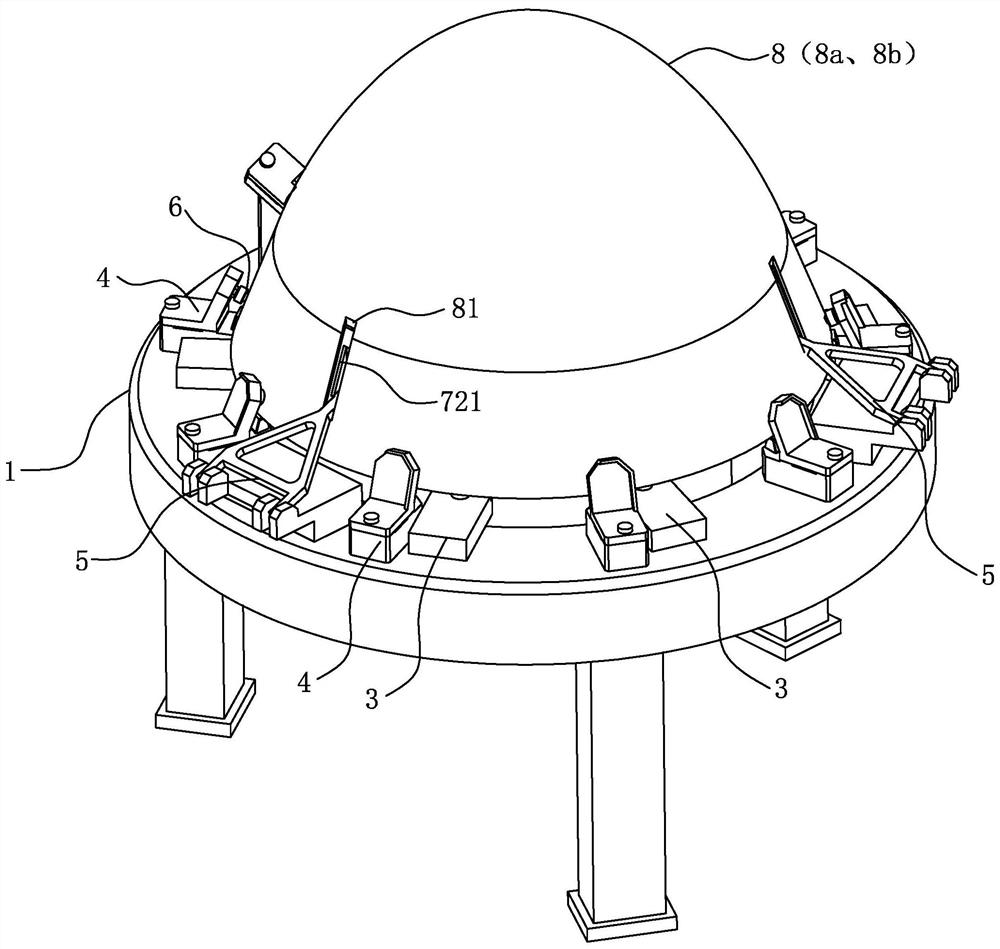

[0031] The radome includes a supporting frame 7, which is installed on a housing 8 outside the supporting frame 7. The supporting frame 7 is provided with a hinge bracket 71, and the upper side of the supporting frame 7 is fixed with a sub-support 72, and the sub-support 72 is provided with a long slot The opening 721, and the housing 8 is provided with a long hole 81 corresponding to the elongated notch 721.

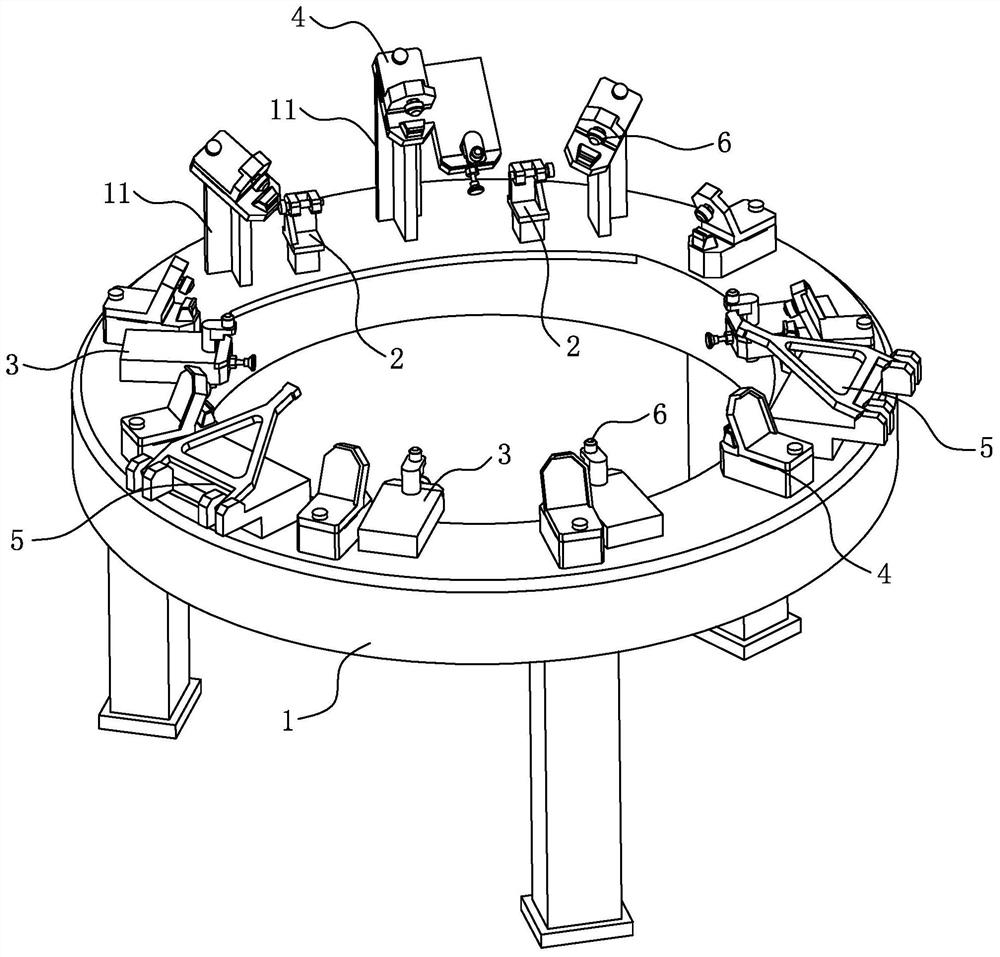

[0032] refer to Figure 1 to Figure 12 As shown, a radome shell replacement and positioning tool includes an annular base 1, a hinge seat 2, a frame support mechanism 3, a shell clamping mechanism 4, a circumferential positioning mechanism 5, and a universal ball mechanism 6;

[0033] The hinge seat 2 is arranged on the annular base 1, and the hinge seat 2 is used to connect and install the hinge bracket 71;

[0034] The universal ball mechanism 6 includes a seat body 61, a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com