Patents

Literature

35results about How to "Deformation will not occur" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

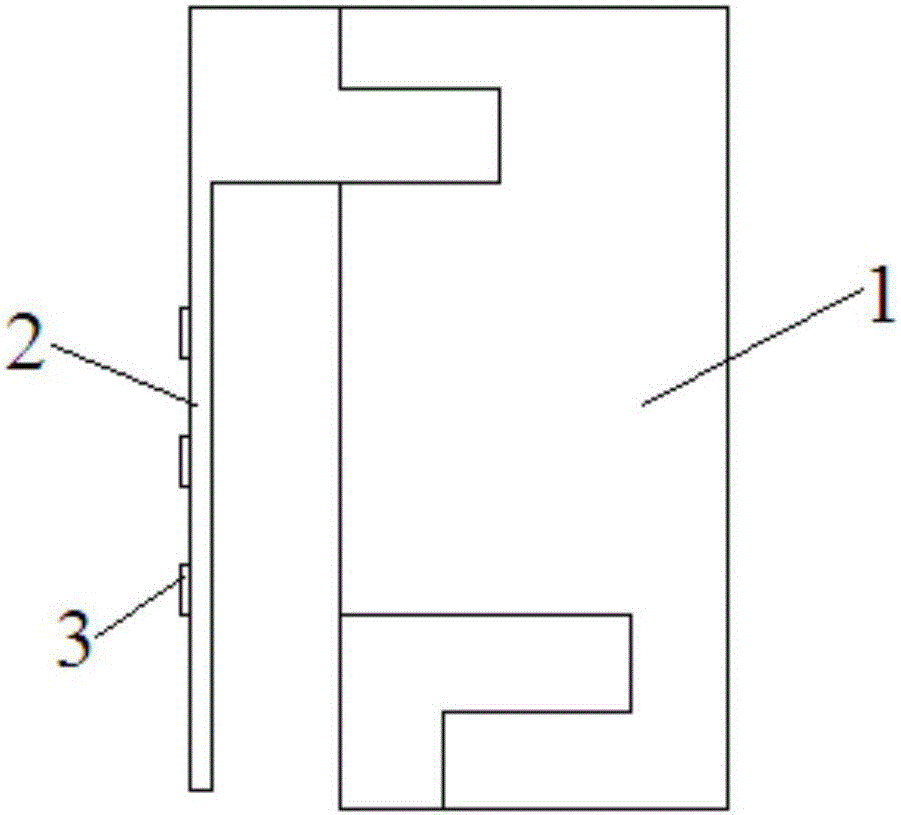

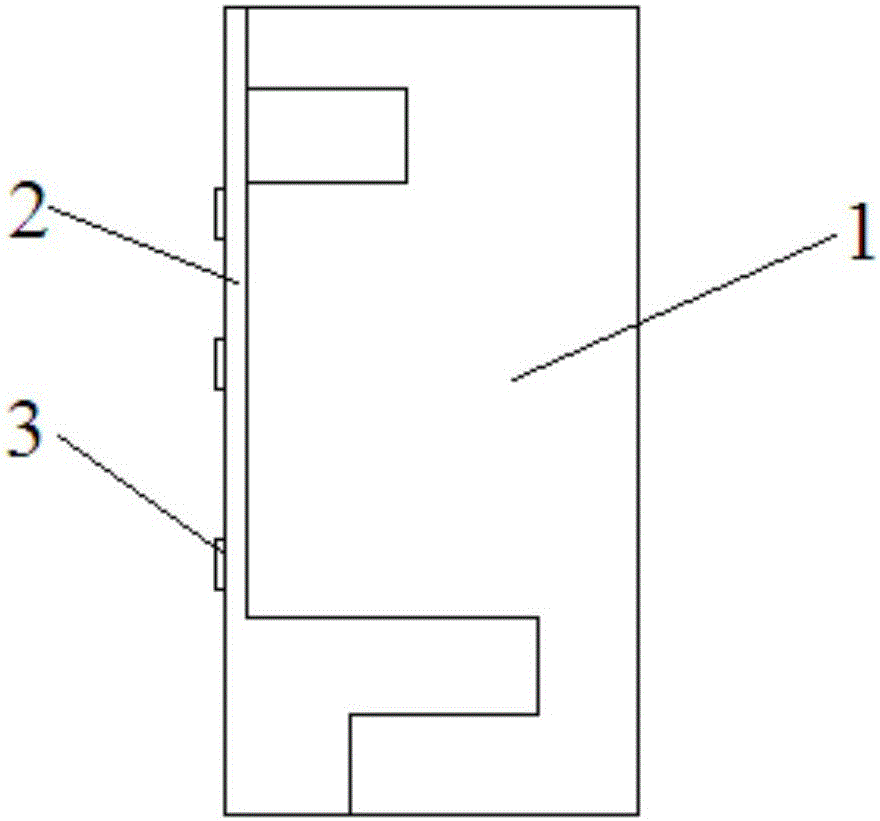

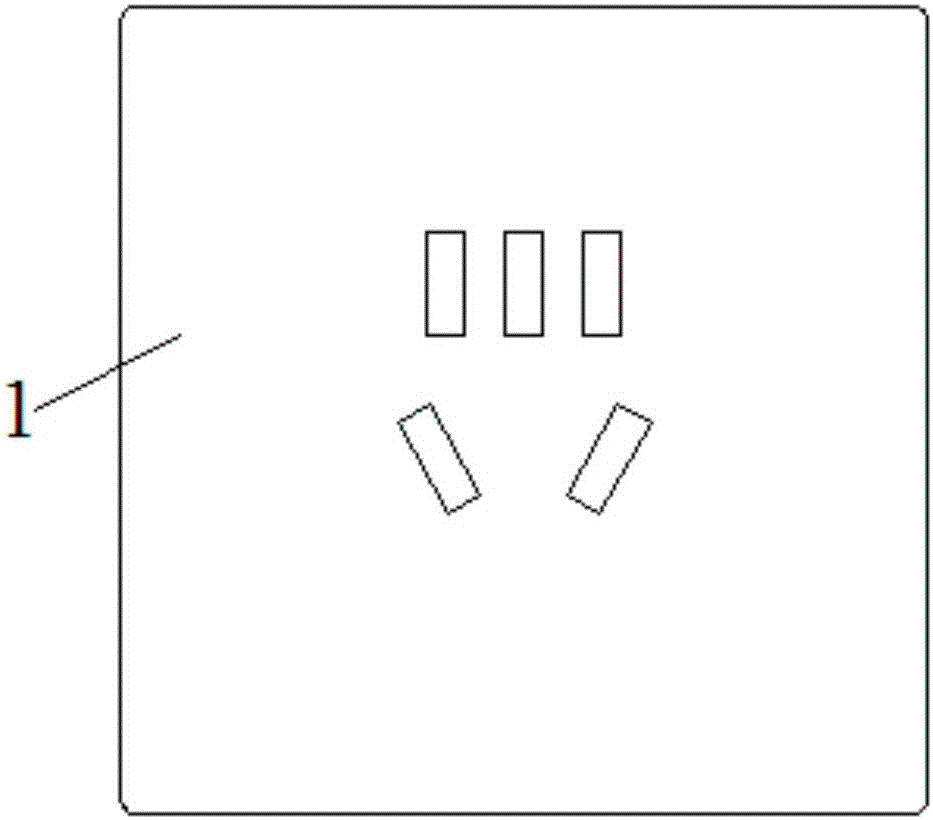

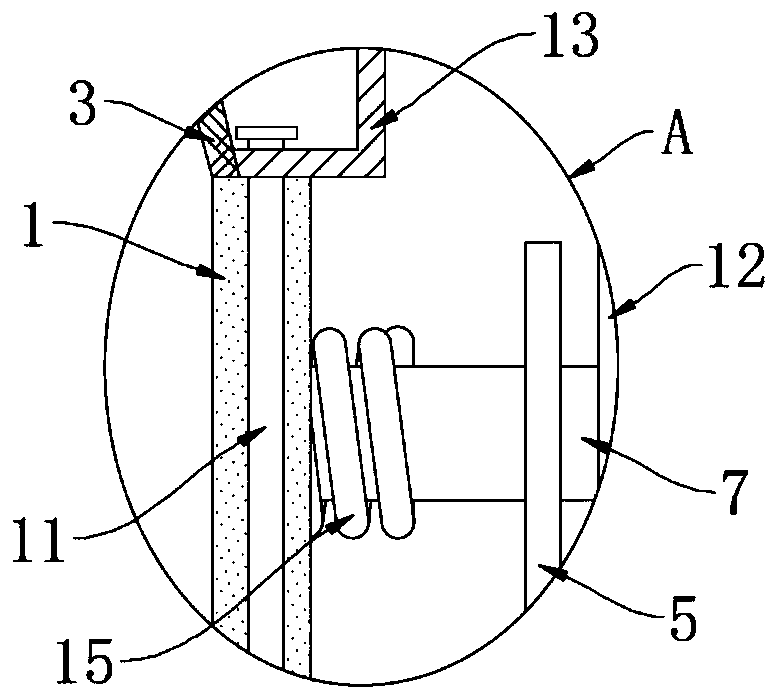

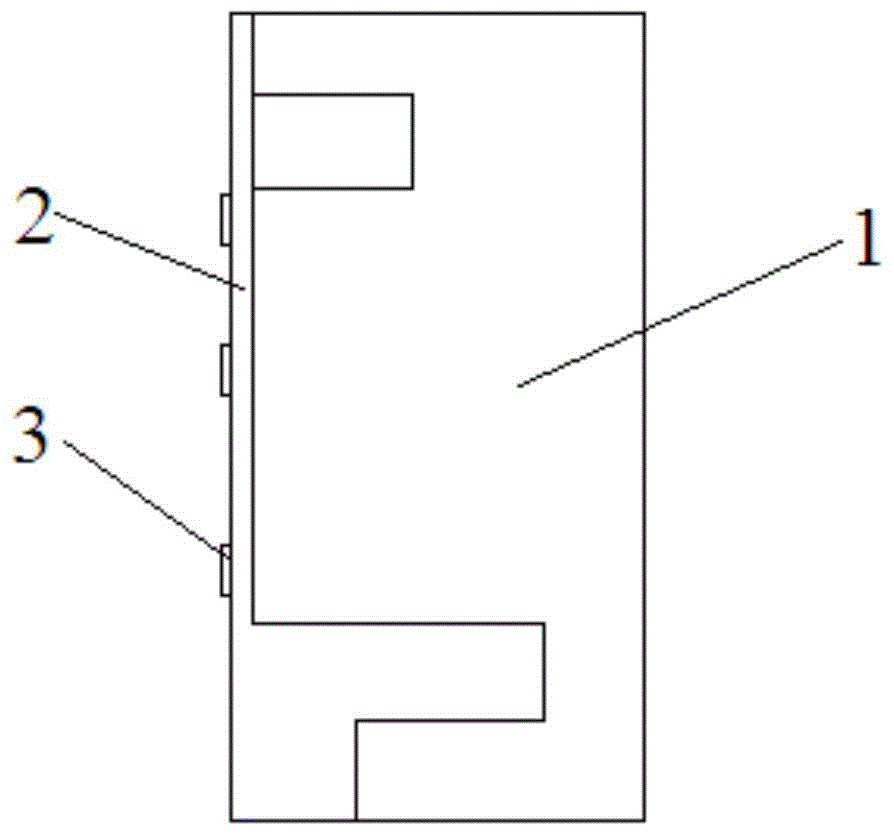

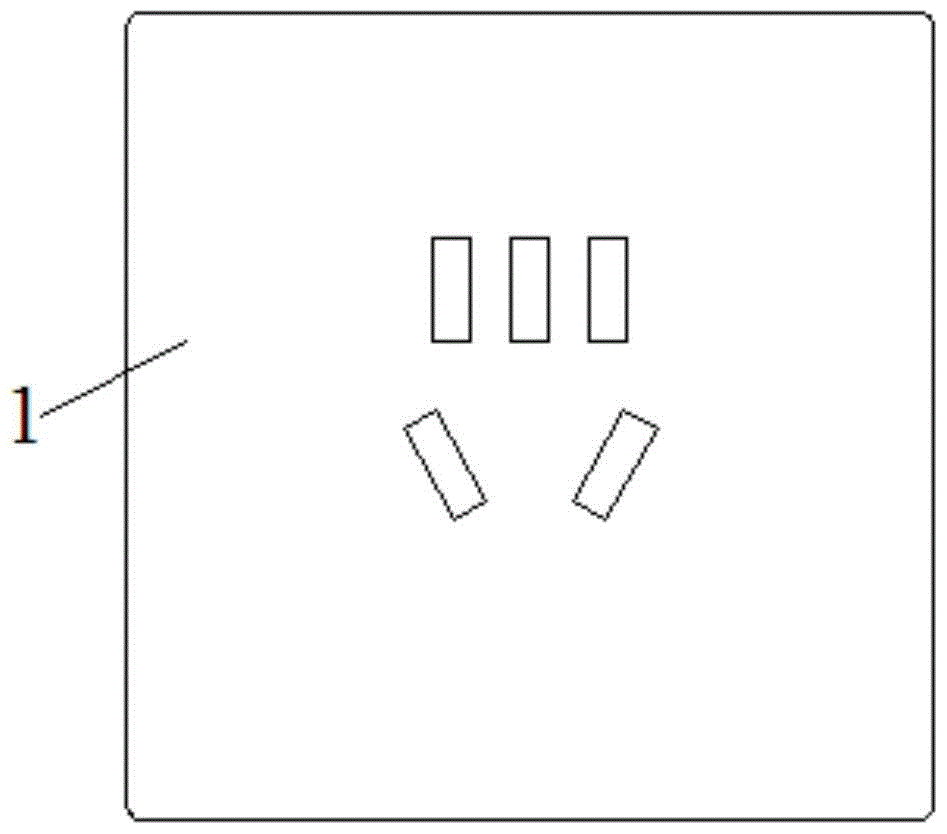

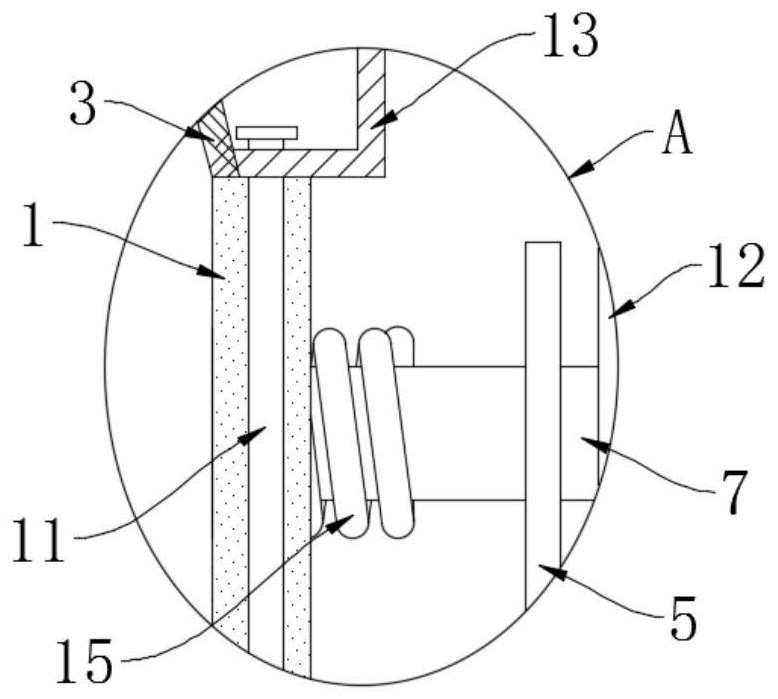

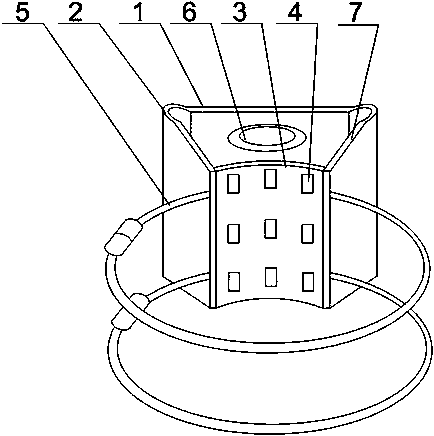

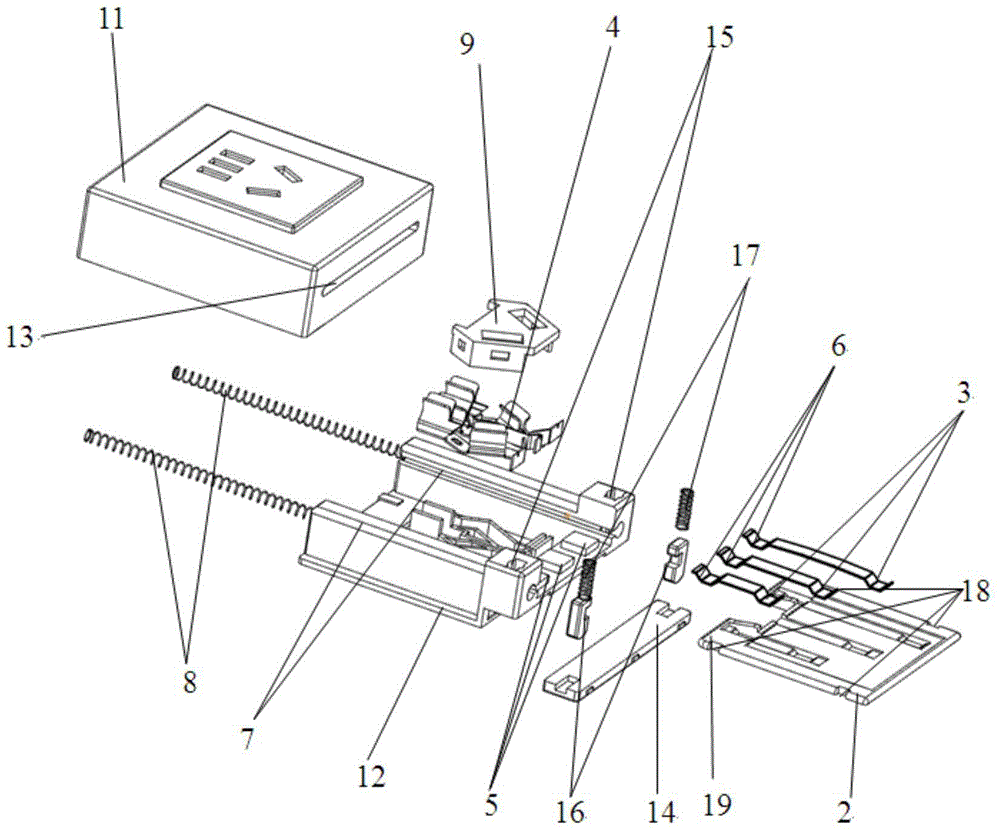

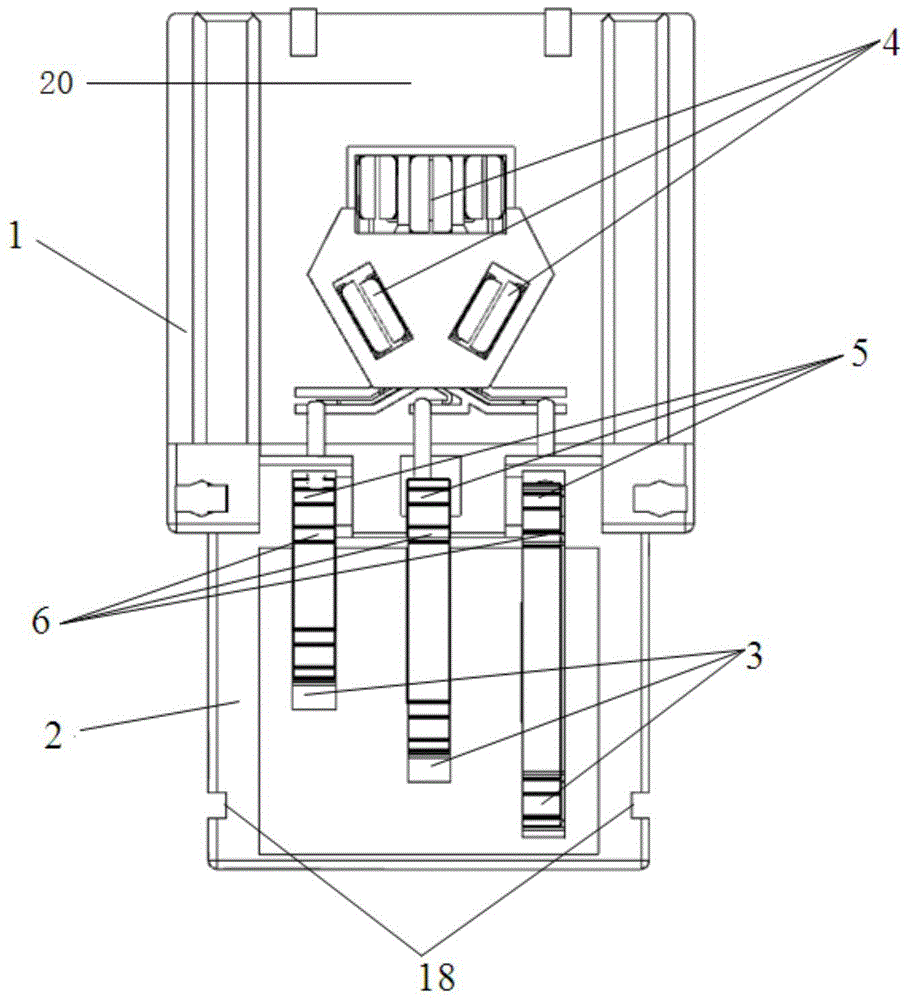

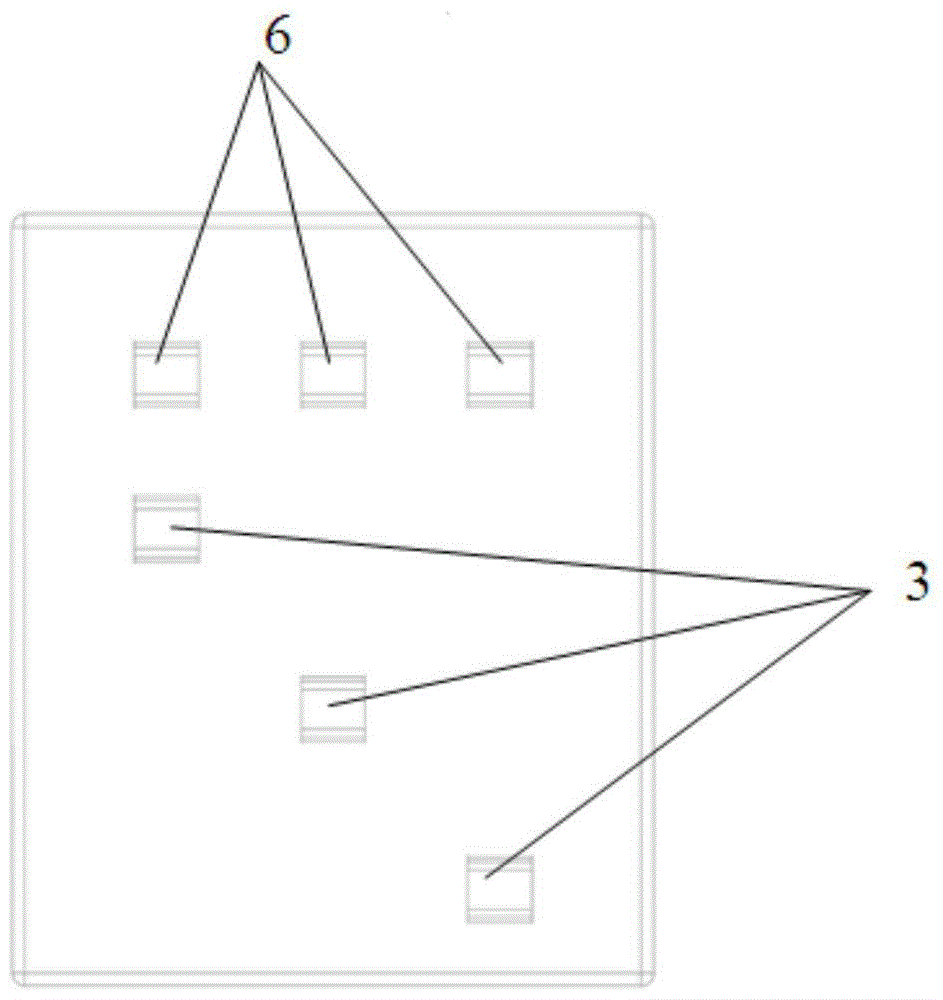

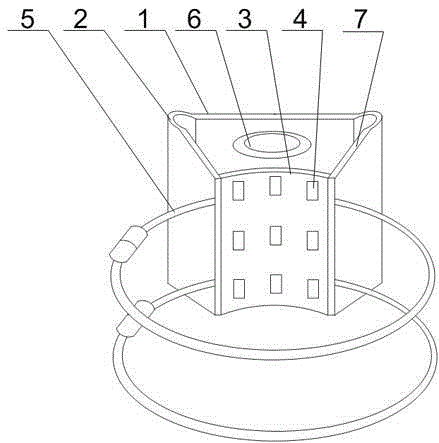

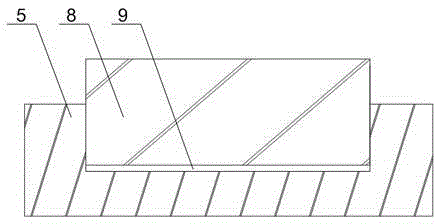

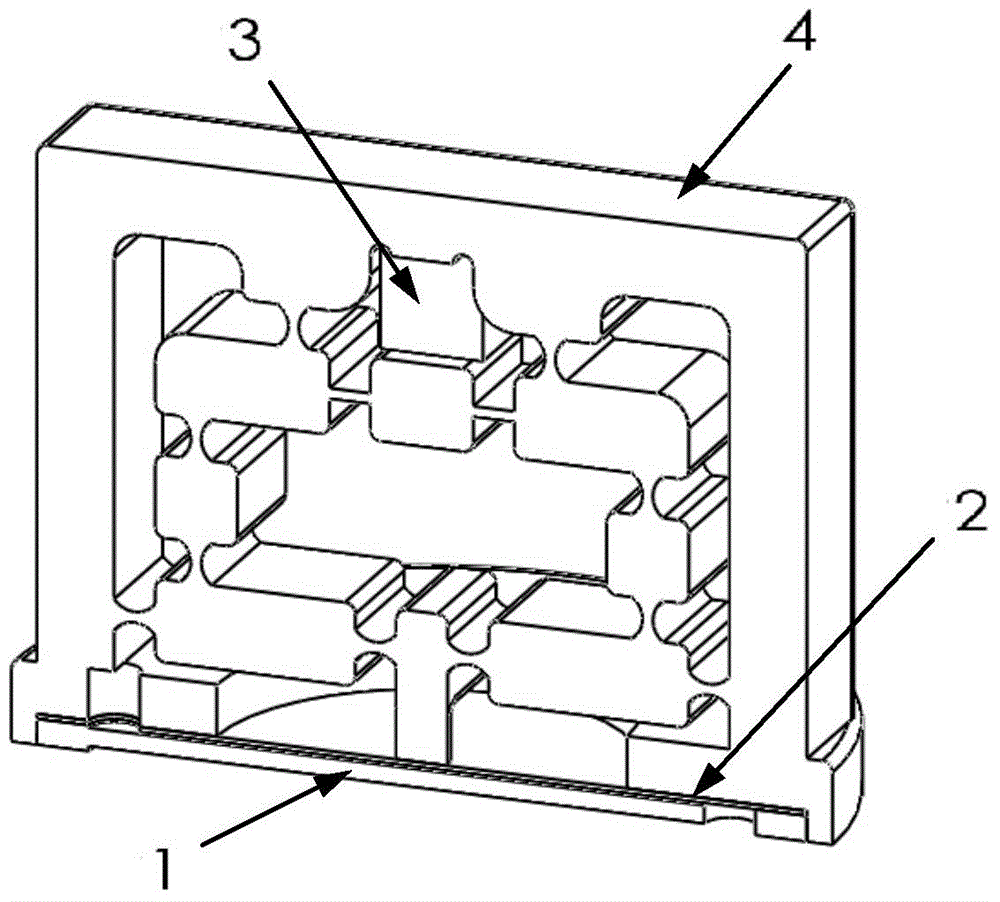

Suspension-type mobile socket

ActiveCN105048232ASimple structureReduce volumeCoupling contact membersTwo-part coupling devicesElectrical conductorEngineering

Owner:SHANUTEC (SHANGHAI) CO LTD

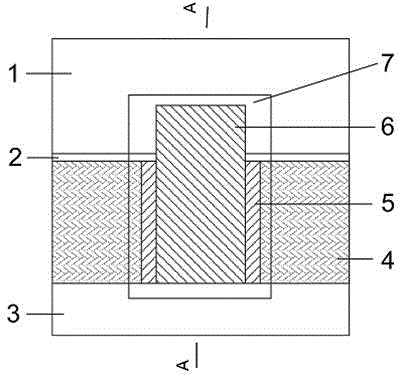

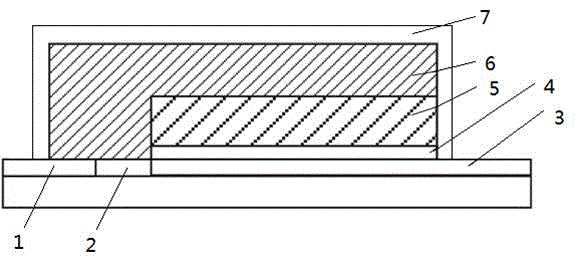

Perovskite solar cell and manufacturing method thereof

InactiveCN104538552ALow costLower internal resistanceSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellEnergy consumption

The invention discloses a perovskite solar cell and a manufacturing method of the perovskite solar cell. The perovskite solar cell is provided with a conducting glass conducting layer, a barrier layer, a mesoporous layer, a counter electrode layer and a perovskite light-absorbing layer. The conducting glass conducting layer is divided into a positive electrode region and a negative electrode region by a piece of insulating tape, the positive electrode region of the conducting glass conducting layer is coated with the barrier layer, the mesoporous layer is located on the barrier layer, the mesoporous layer, the insulating tape and the positive electrode region of the conducting glass conducting layer are covered with the counter electrode layer, and the outer surface of the counter electrode layer is coated with the perovskite light-absorbing layer. The low-cost screen printing technology is fully utilized, the production process is simple, the energy consumption of the low-cost screen printing technology is much lower than that of the evaporation coating technology, and the manufacturing method of the perovskite solar cell is beneficial for large-scale production and has broad application prospects.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

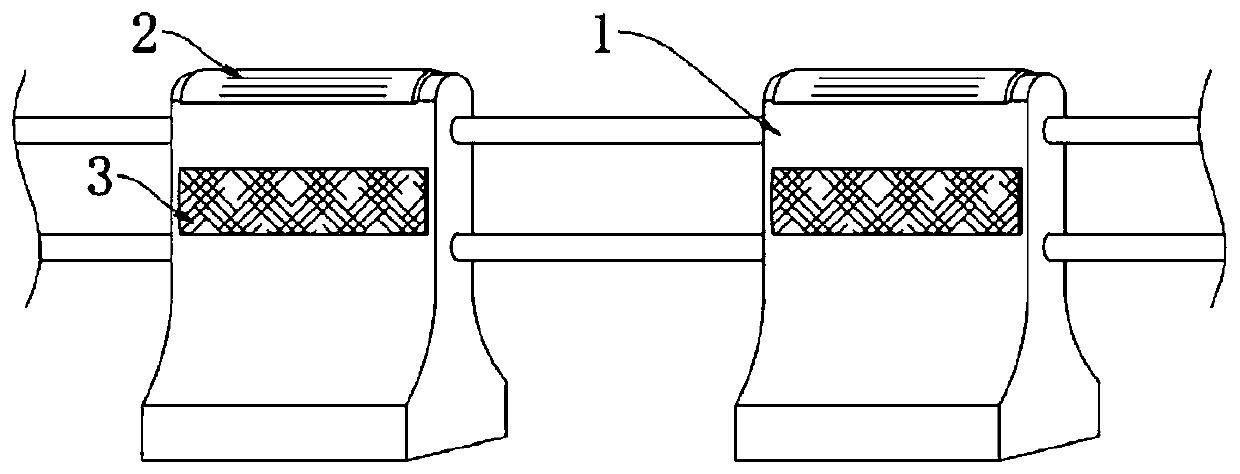

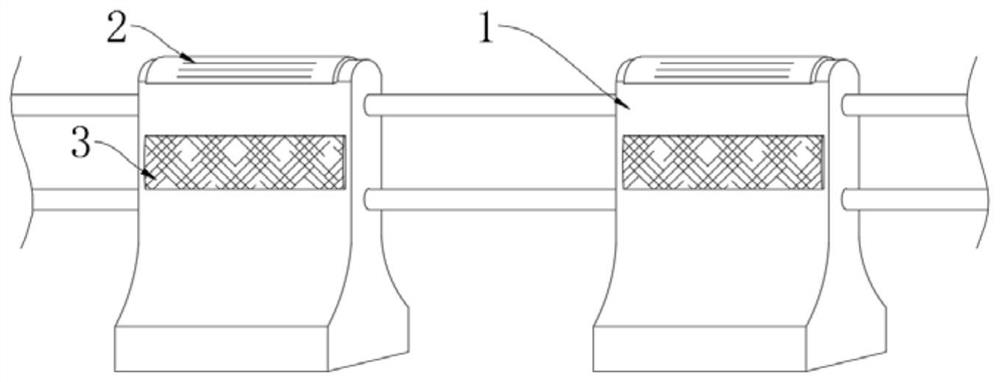

Road isolation fence for buffering and warning

InactiveCN110924333AShort timeReduce impact speedMachines/enginesTraffic signalsEmbedded systemAutomotive engineering

The invention discloses a road isolation fence for buffering and warning. Isolation pile, a warning lamp is mounted at the top of the isolation pile; two square grooves are symmetrically formed in theside wall of the isolation pile, an air bag is glued to the side wall of the isolation pile, an induction cavity is formed in the isolation pile, the induction cavity is communicated with the two square grooves, a storage box is fixedly arranged on the side, close to the induction cavity, of each square groove, and a circuit box is fixedly installed in the middle of the induction cavity. Rigid collision between a vehicle and the isolation pile is converted into elastic collision between the vehicle and the air bag when an accident occurs, so that the impact force between the vehicle and the air bag is reduced, the buffer to the vehicle is increased, the protection effect of the isolation pile is improved, and the isolation pile can be prevented from being seriously damaged; after collision, the warning lamps on the isolation piles automatically emit light and can be kept for a certain period of time, so that other drivers are reminded to avoid accident vehicles in time, and chain traffic accidents and rear-end collisions are reduced.

Owner:商河园通市政工程有限公司

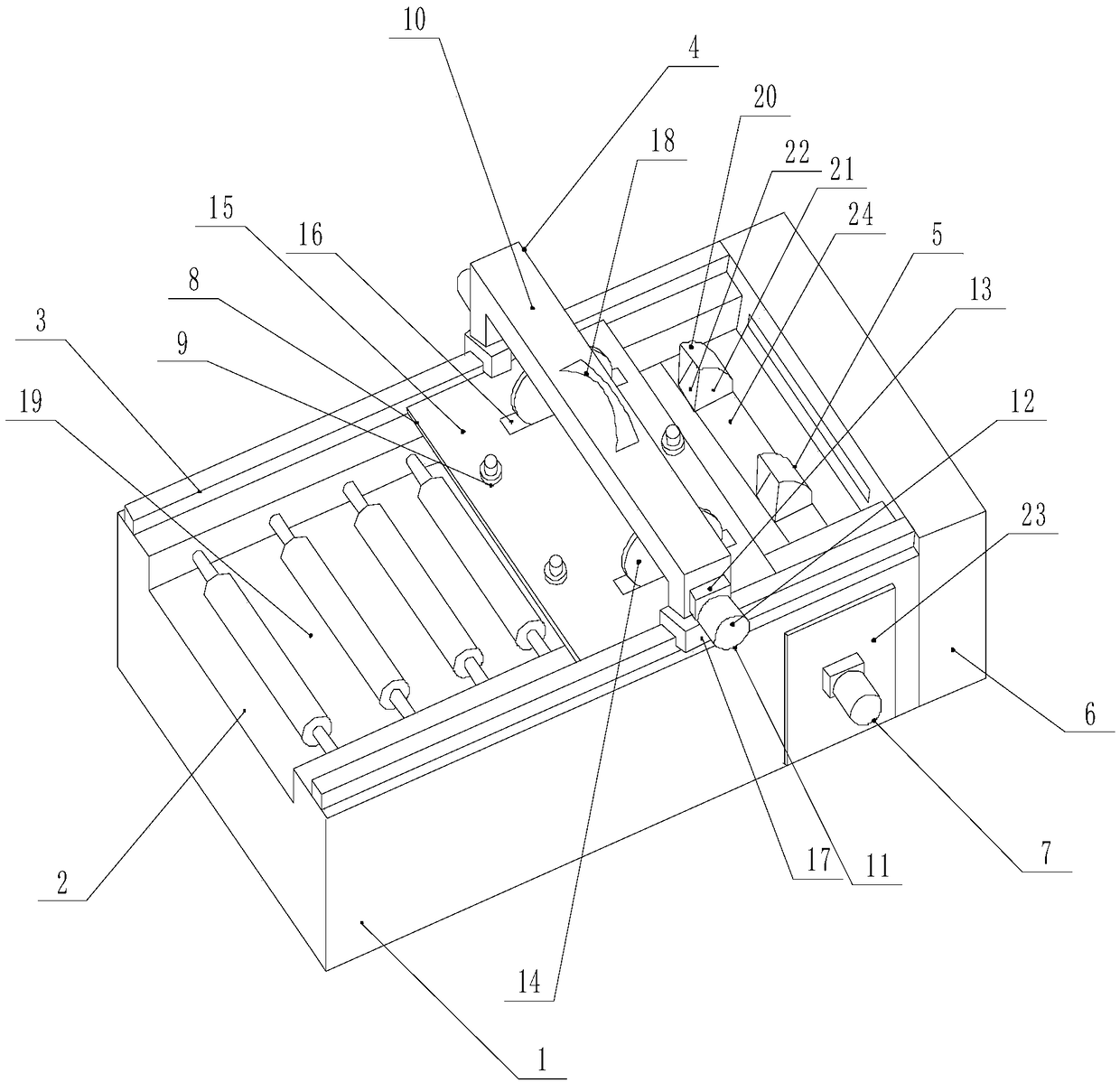

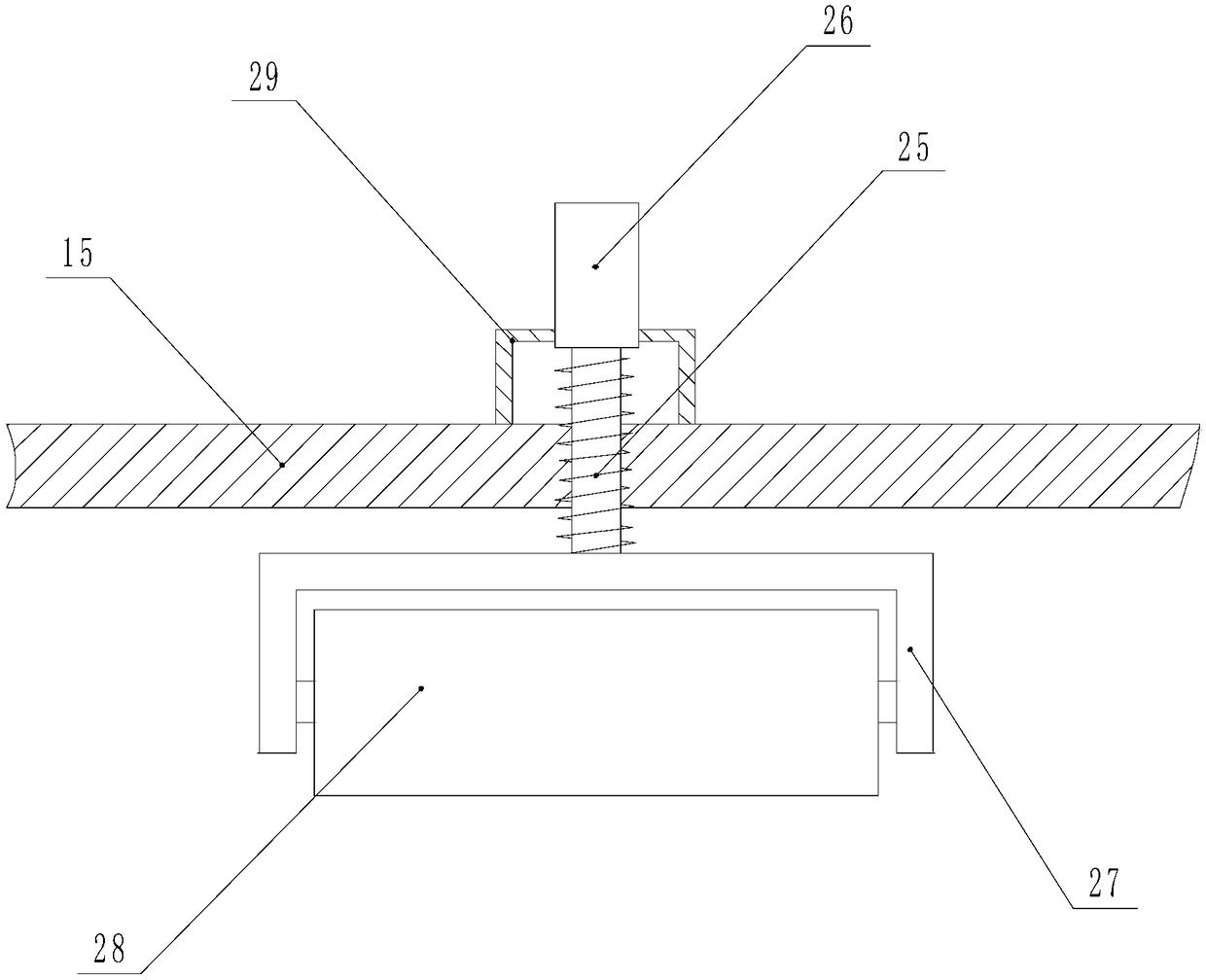

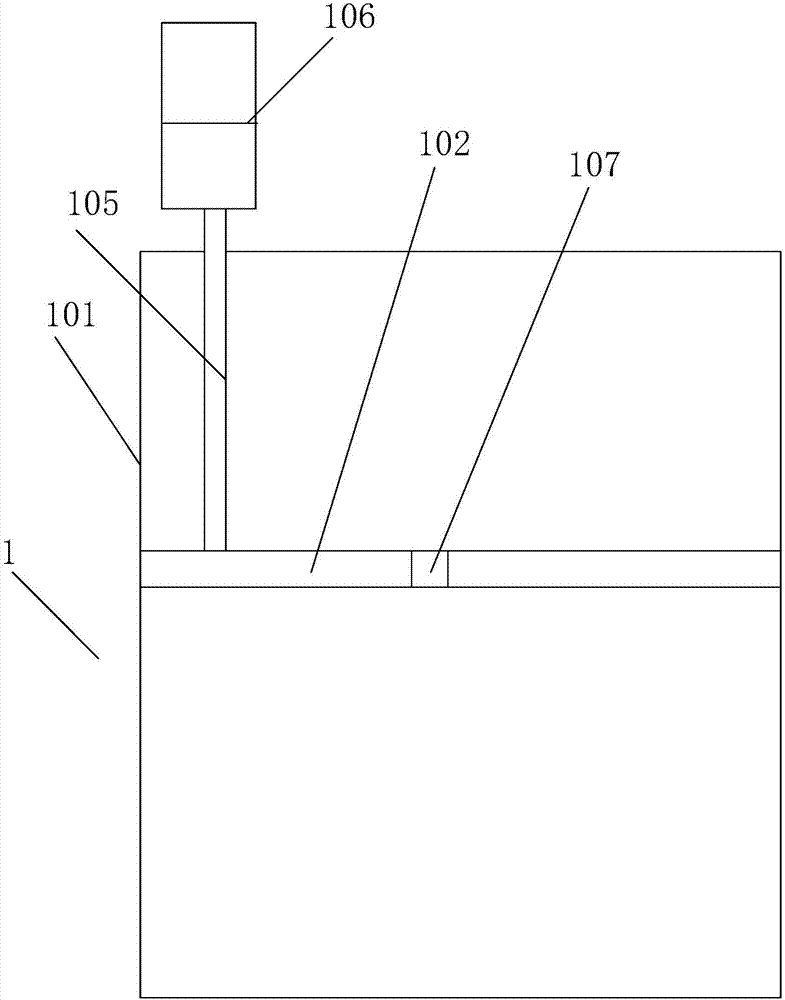

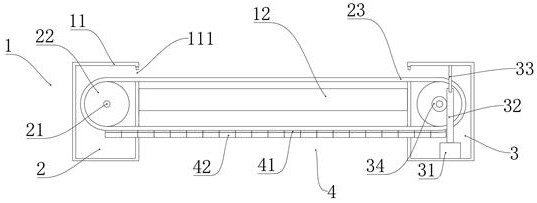

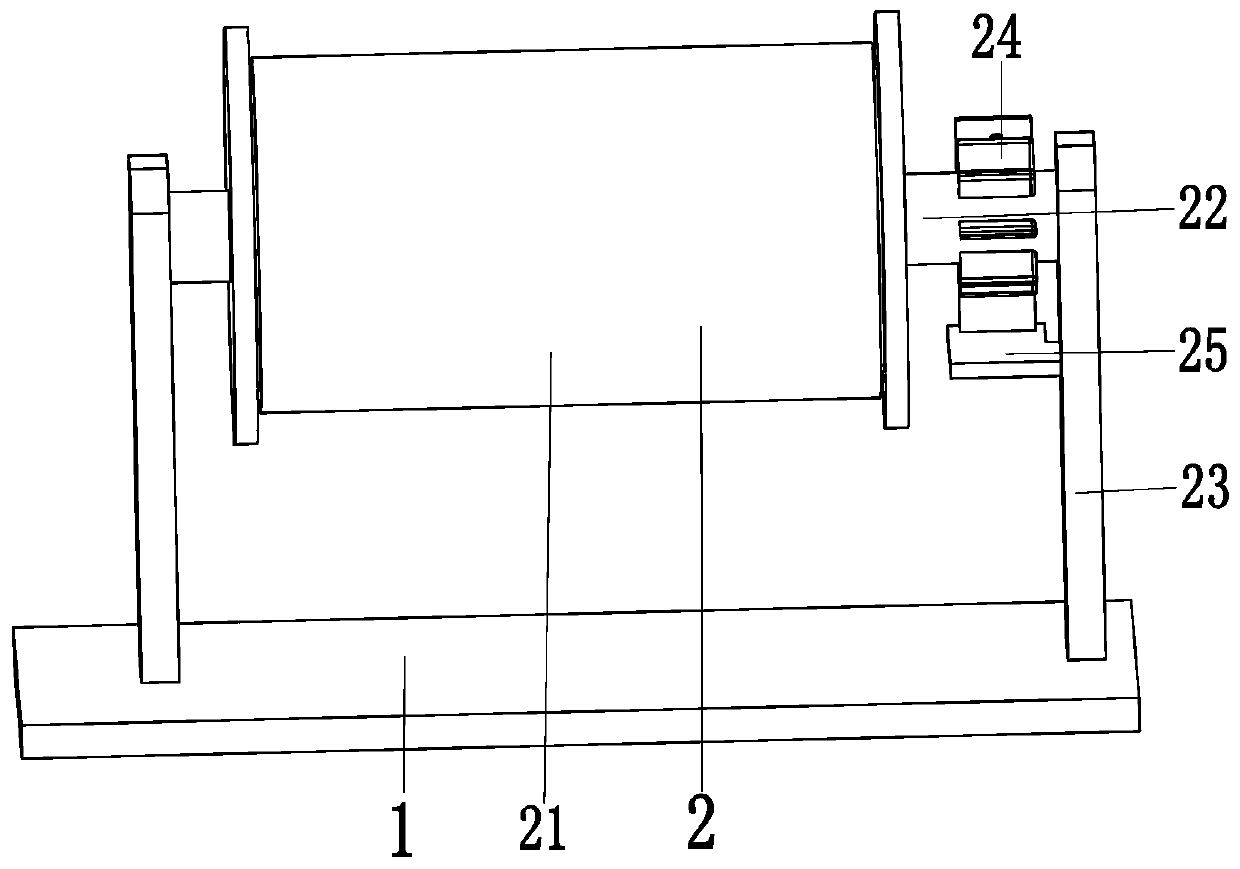

High-stability steel plate cutting device

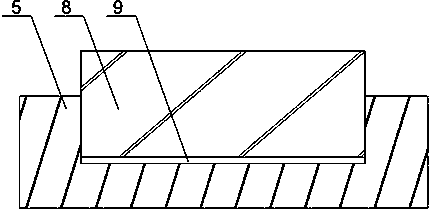

InactiveCN108161099ASolve the problem of easy deformationDeformation will not occurShearing machinesShearing machine accessoriesSheet steelEngineering

The invention provides a high-stability steel plate cutting device. The cutting device comprises a machine frame and a workbench arranged on the machine frame; a driving device used for pulling a steel plate is arranged at the rear portion of the machine frame, a pressing device and a cutting device body are arranged on the workbench, and guide rails are arranged on the two sides of the workbench;and the pressing device comprises a pressing plate arranged between the two guide rails, and rolling shafts arranged below the pressing plate, and knife passing openings and an adjusting assembly used for adjusting the rolling shafts to move up and down are arranged on the pressing plate. According to the cutting device, the problem that a thin steel plate is prone to deform in the edge cutting process is solved, and the edge cutting machine is simple in structure, and is very convenient to operate; the thin steel plate cannot deform when being cut through the arranged pressing mechanism, sothat the cutting precision of the thin steel plate edge cutting is greatly improved, and the qualified rate of the thin steel plate is improved; and the thin steel plates with different thicknesses and shapes can be accurately cut by adjusting the rolling shafts to press the thin steel plates.

Owner:新昌县鼎绑机电有限公司

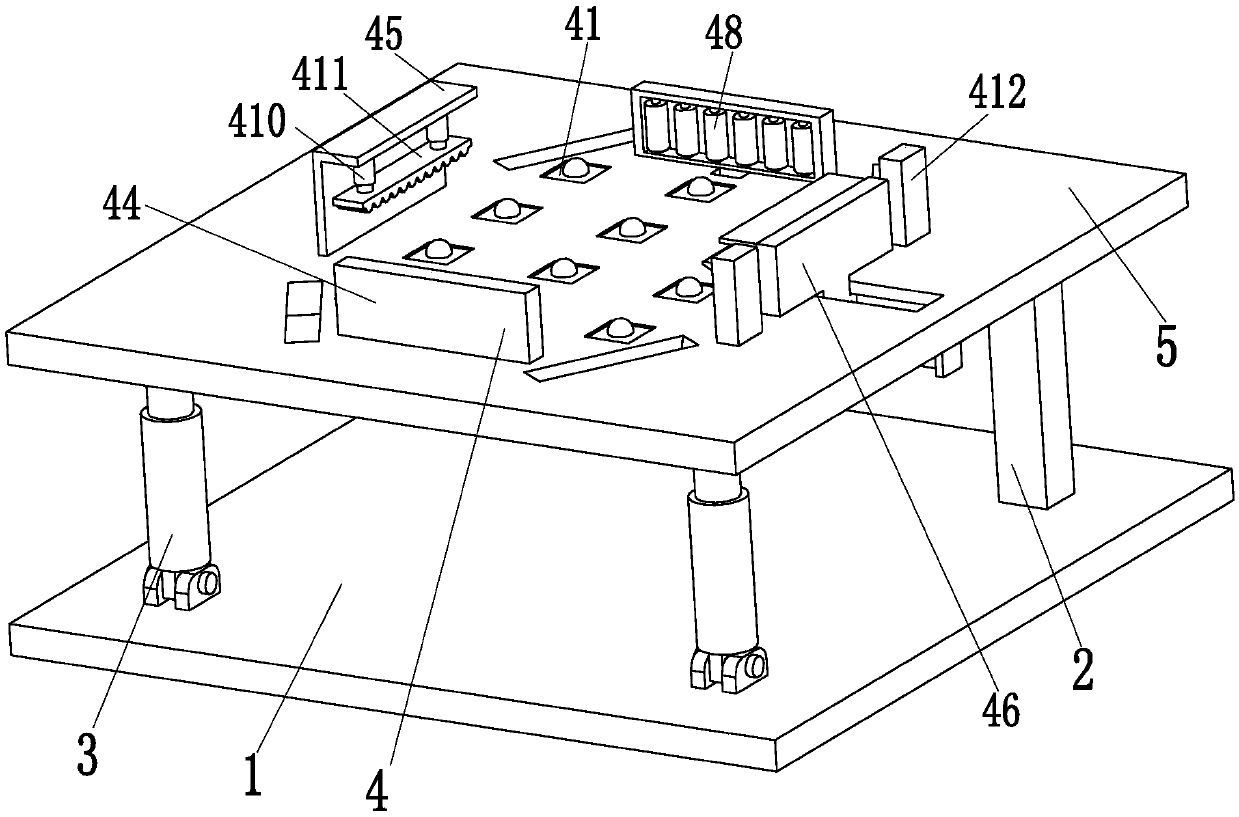

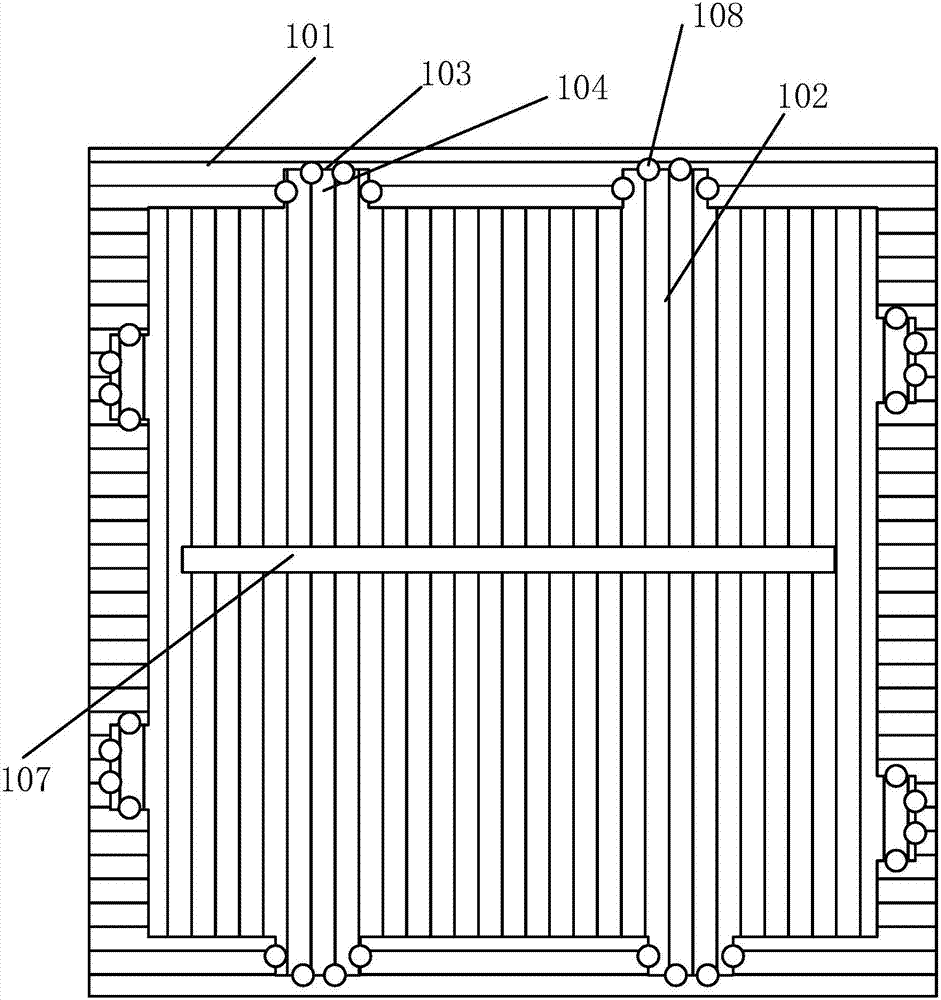

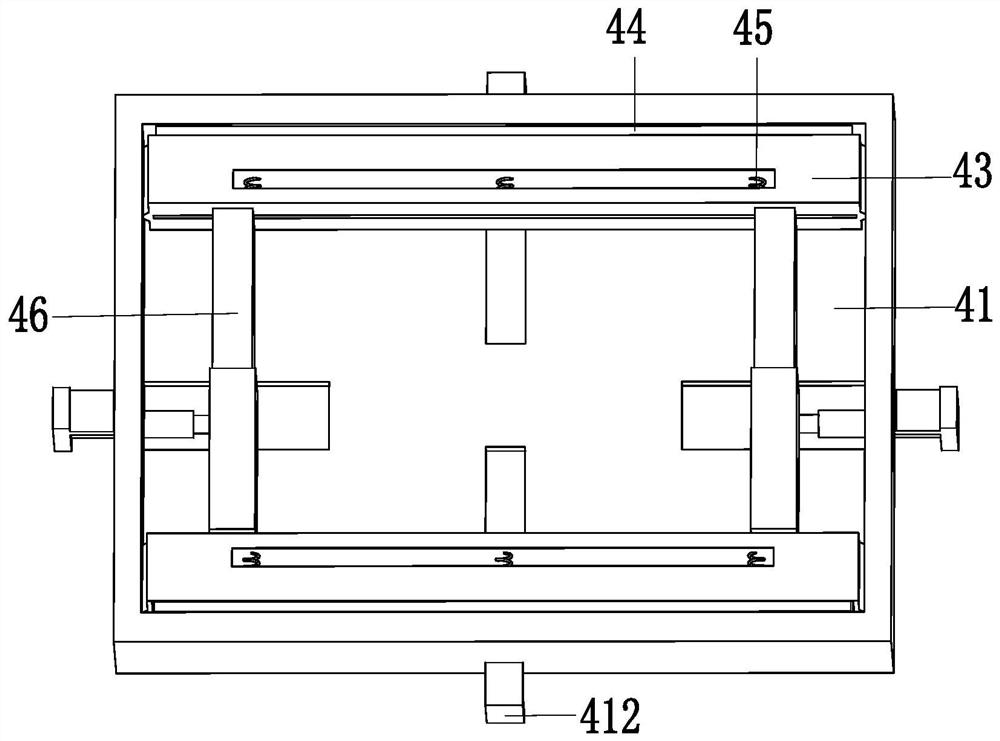

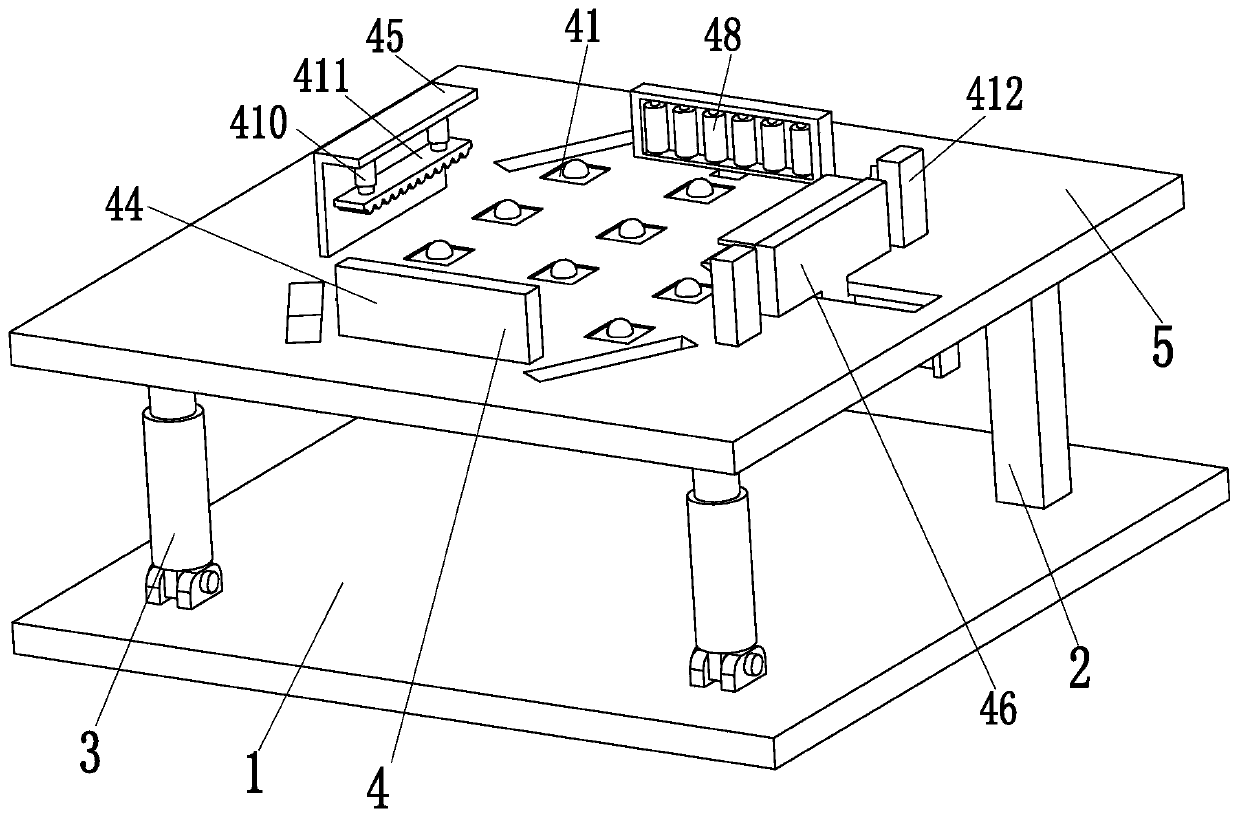

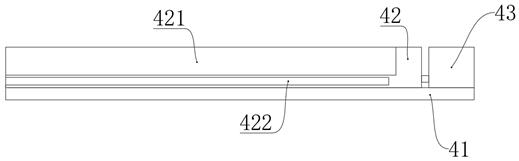

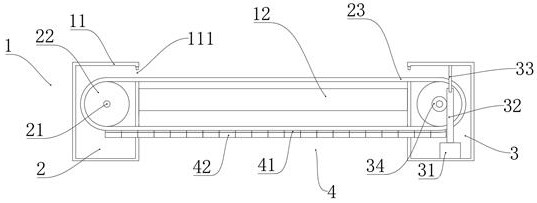

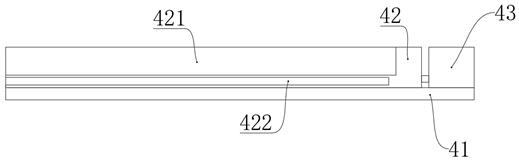

Automatic plate material finely cutting system

ActiveCN109604703AStable position adjustmentDeformation will not occurShearing machinesShearing machine accessoriesHydraulic cylinderMechanical engineering

The invention relates to an automatic plate material finely cutting system. The automatic plate material finely cutting system comprises a supporting bottom plate, supporting columns, angle hydrauliccylinders, a positioning device, a positioning supporting plate, and cutting devices. The supporting columns are mounted on the top of the rear end of the supporting bottom plate. The rear end of thepositioning supporting plate is mounted on the tops of the supporting columns by hinges. The angle hydraulic cylinders are arranged at the bottom of the front end of the positioning supporting plate.The angle hydraulic cylinders are mounted between the supporting bottom plate and the positioning supporting plate by hinges. Cutting grooves are symmetrically formed in the outer end of the positioning supporting plate. The positioning device is mounted on the positioning supporting plate. The cutting devices are located at the upper end of the positioning supporting plate. The cutting devices are mounted on the top of the outer end of the supporting bottom plate. The automatic plate material finely cutting system can solve the problems that when corners of existing steel plates are cut, thesteel plates with different sizes can not be positioned, steel plate position adjusting is not smooth, steel plate cutting with different cutting edge inclinations can not be achieved, and the steel plates deform during cutting.

Owner:杭州宝伟汽车零部件有限公司

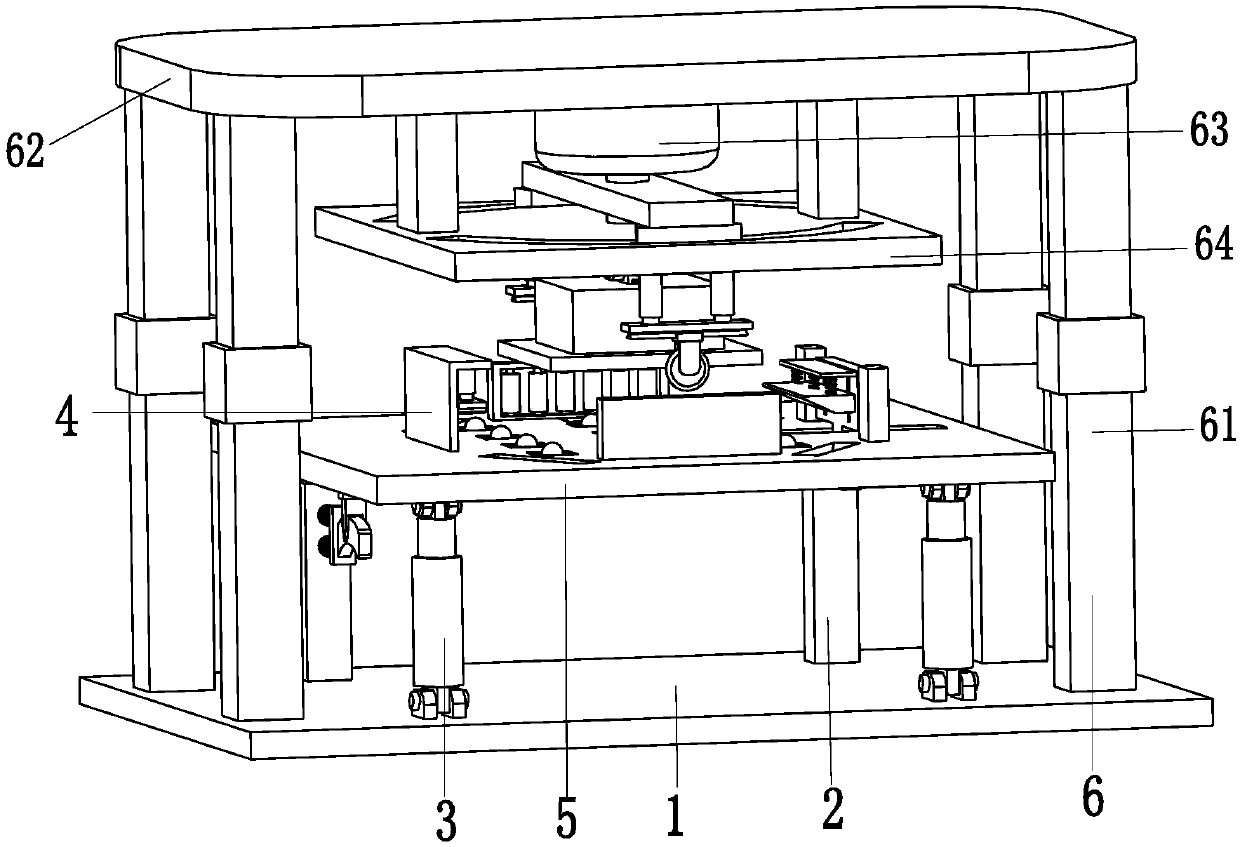

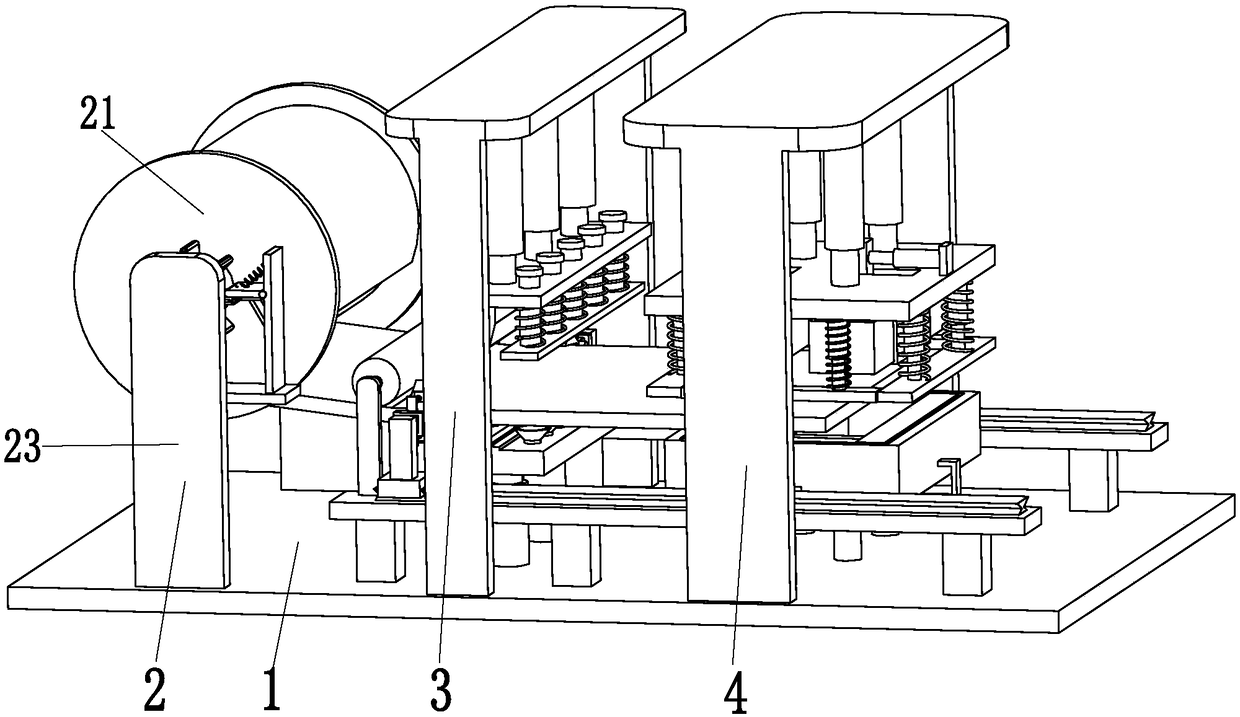

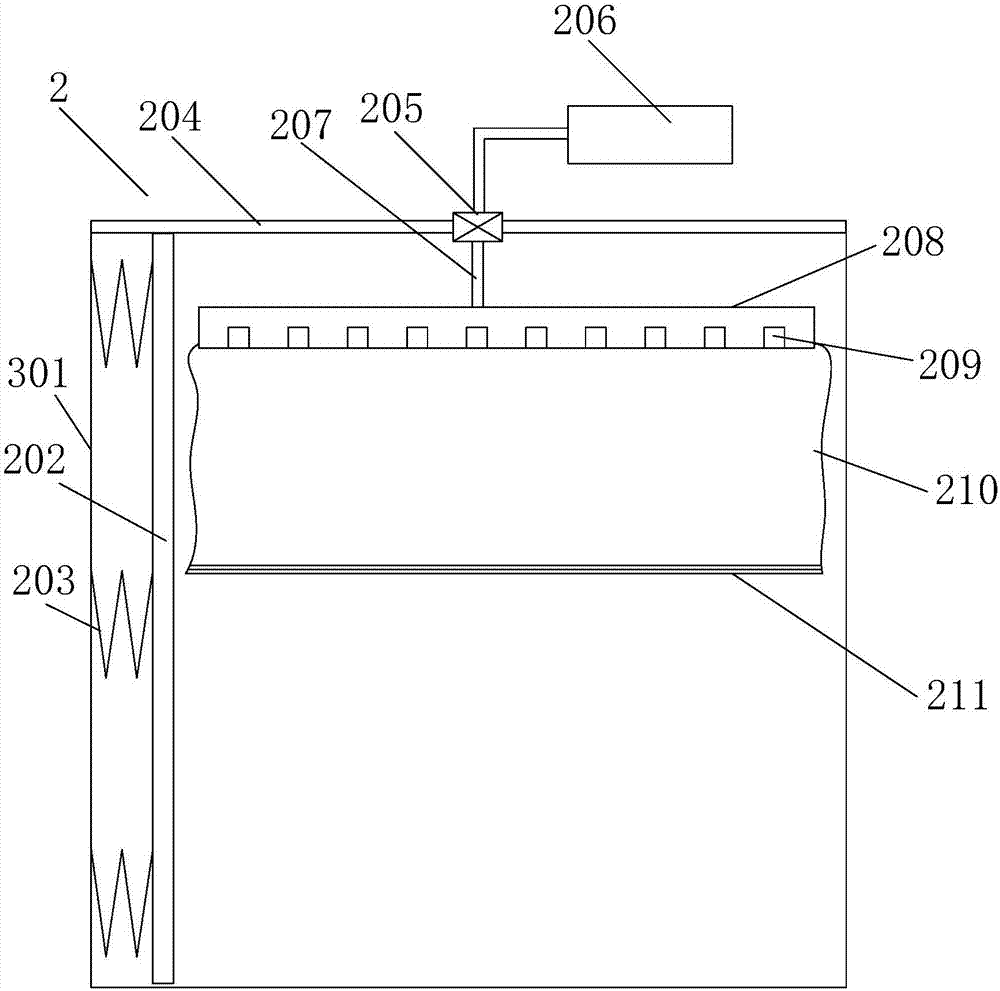

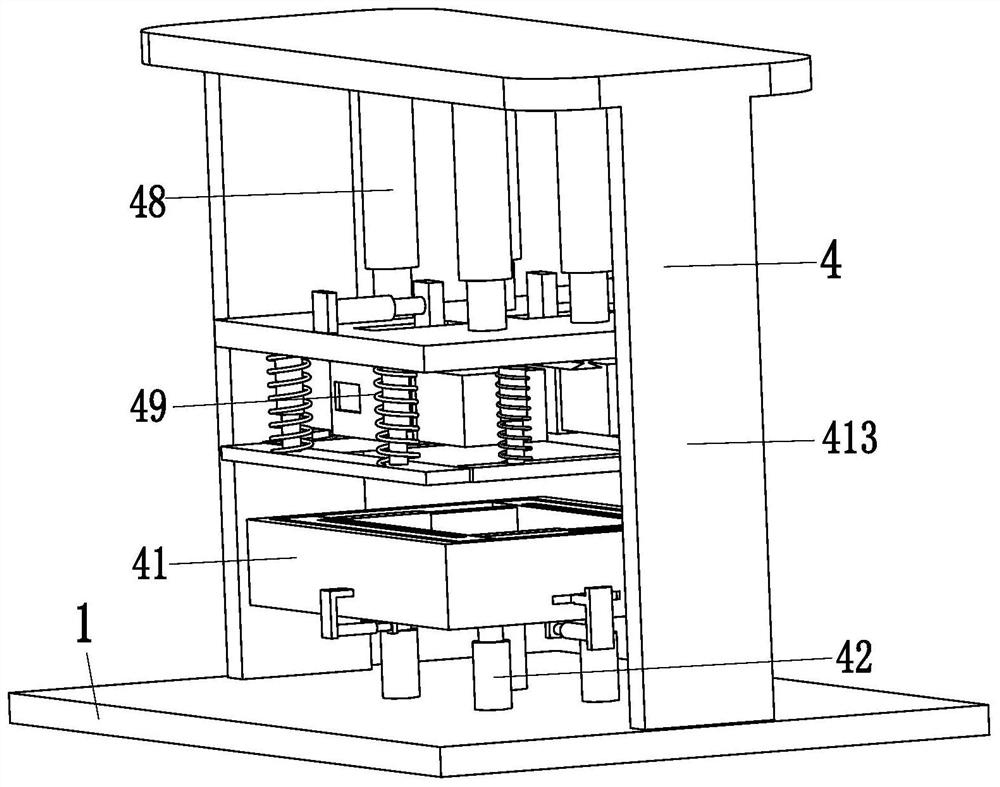

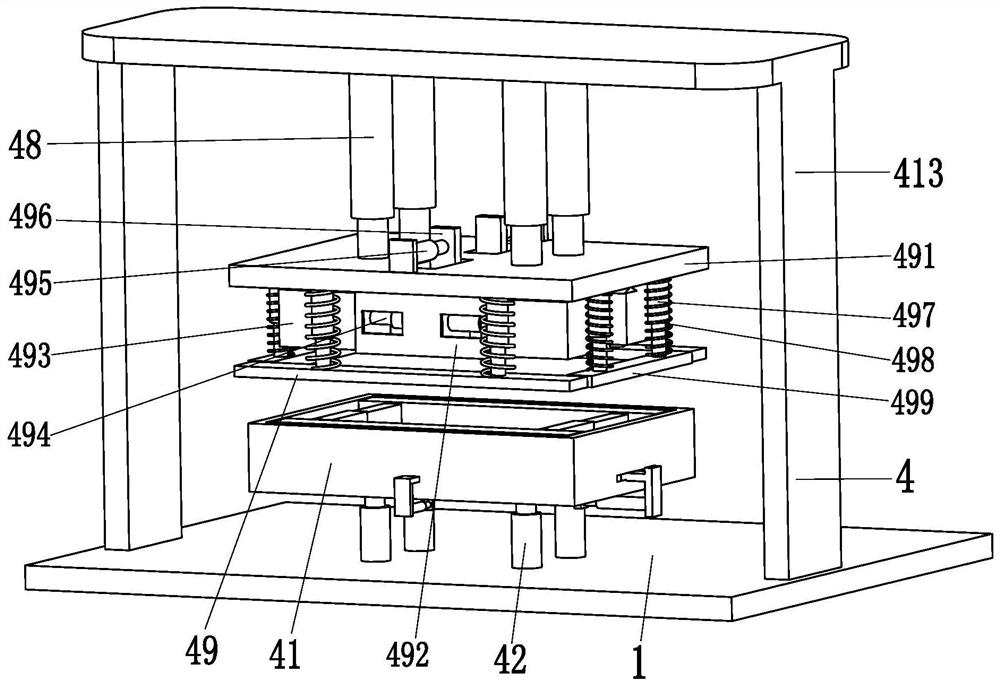

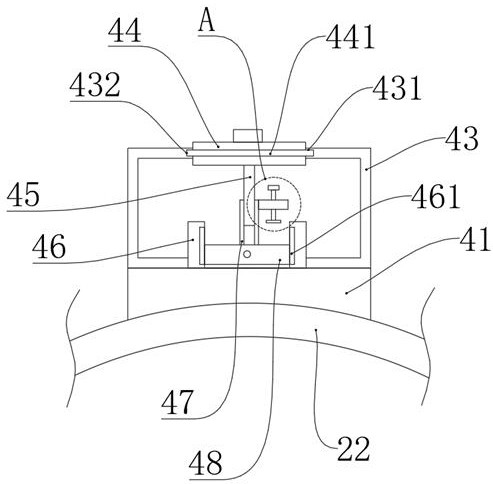

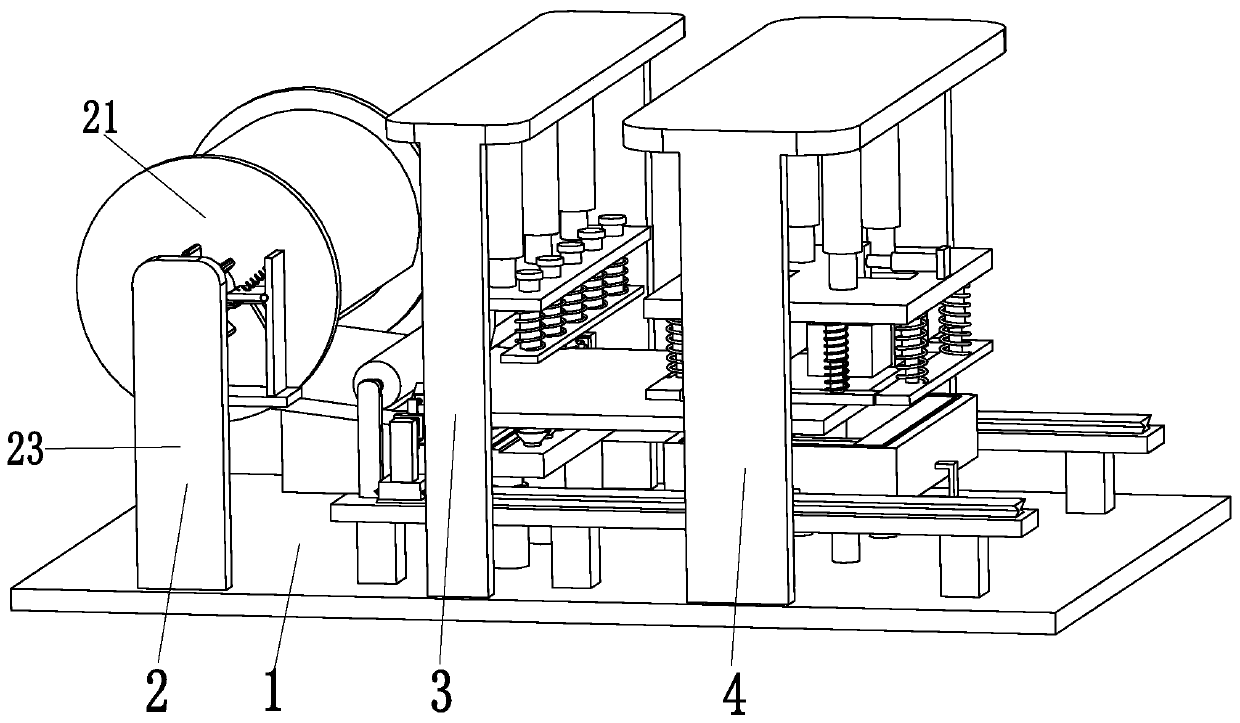

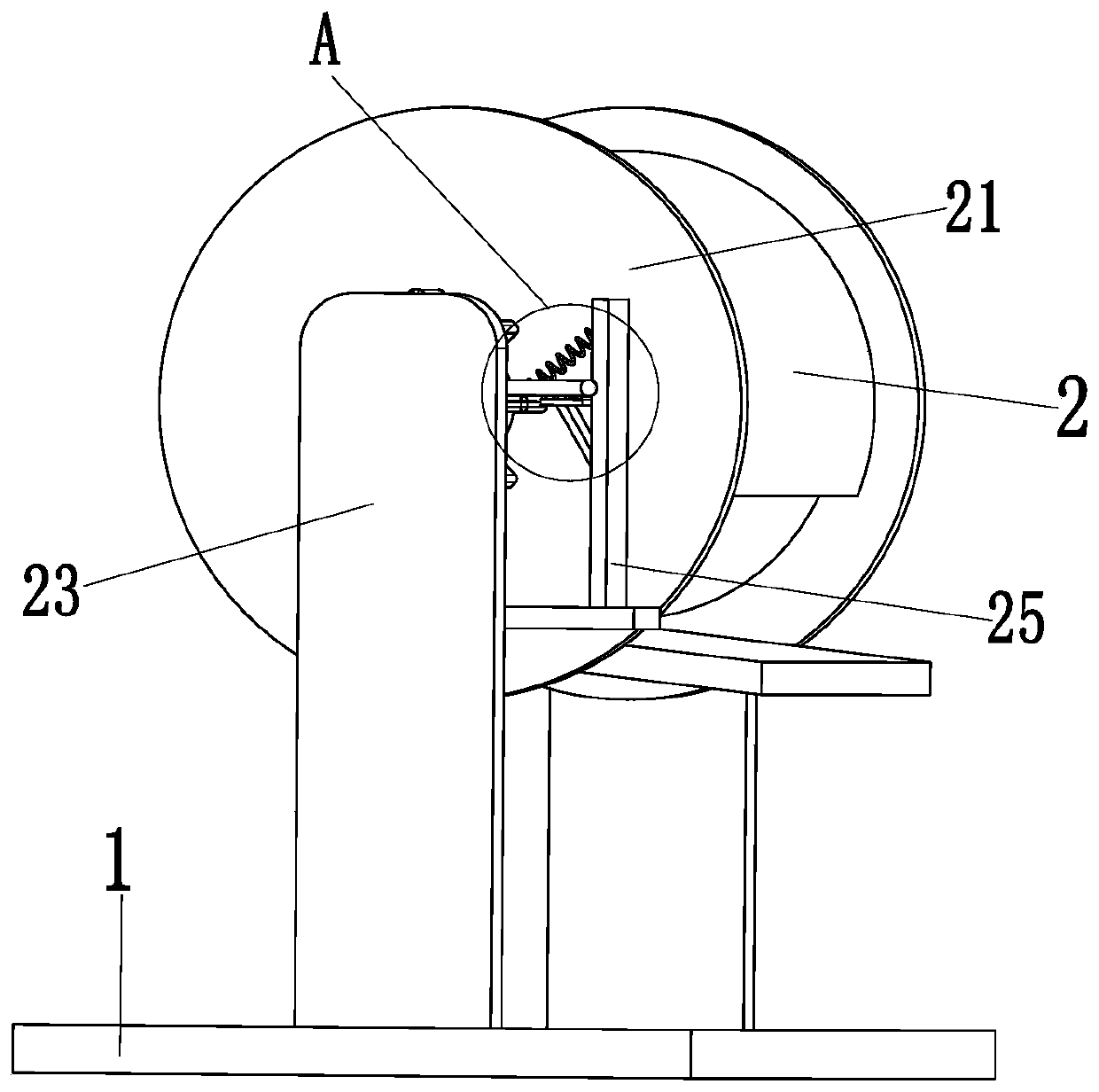

Stamping equipment for soft-package lithium battery aluminum-plastic film and stamping machining process of stamping equipment

ActiveCN109176692AWrinkling does not occurImprove cutting effectSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsPlastic filmMachining process

The invention relates to stamping equipment for a soft-package lithium battery aluminum-plastic film and a stamping machining process of the stamping equipment. The stamping equipment comprises a supporting bottom board, a conveying device, a cutting device and a stamping device, wherein the conveying device is installed on the top of the left end of the supporting bottom board; the cutting deviceis installed in the middle of the supporting bottom board; the stamping device is connected with the top of the right end of the supporting bottom board; and the conveying device comprises a conveying roll, a conveying rotary shaft, a rotary shaft supporting plate, a stirring plate, a buffer connection frame, a rotating plate, a barrier frame and a buffer spring. By means of the stamping equipment, the problems that in the stamping process of existing aluminum-plastic films of external packages of soft-package lithium batteries, the aluminum-plastic films cannot be automatically conveyed andwrinkle when conveyed, the stamping size of a stamping die cannot be adjusted, the peripheral portions of the aluminum-plastic films deform in the stamping process of the aluminum-plastic films, consequently, the aluminum-plastic films cannot be automatically cut and the aluminum-plastic film cutting effect is poor can be solved.

Owner:赣州诺威新能源有限公司

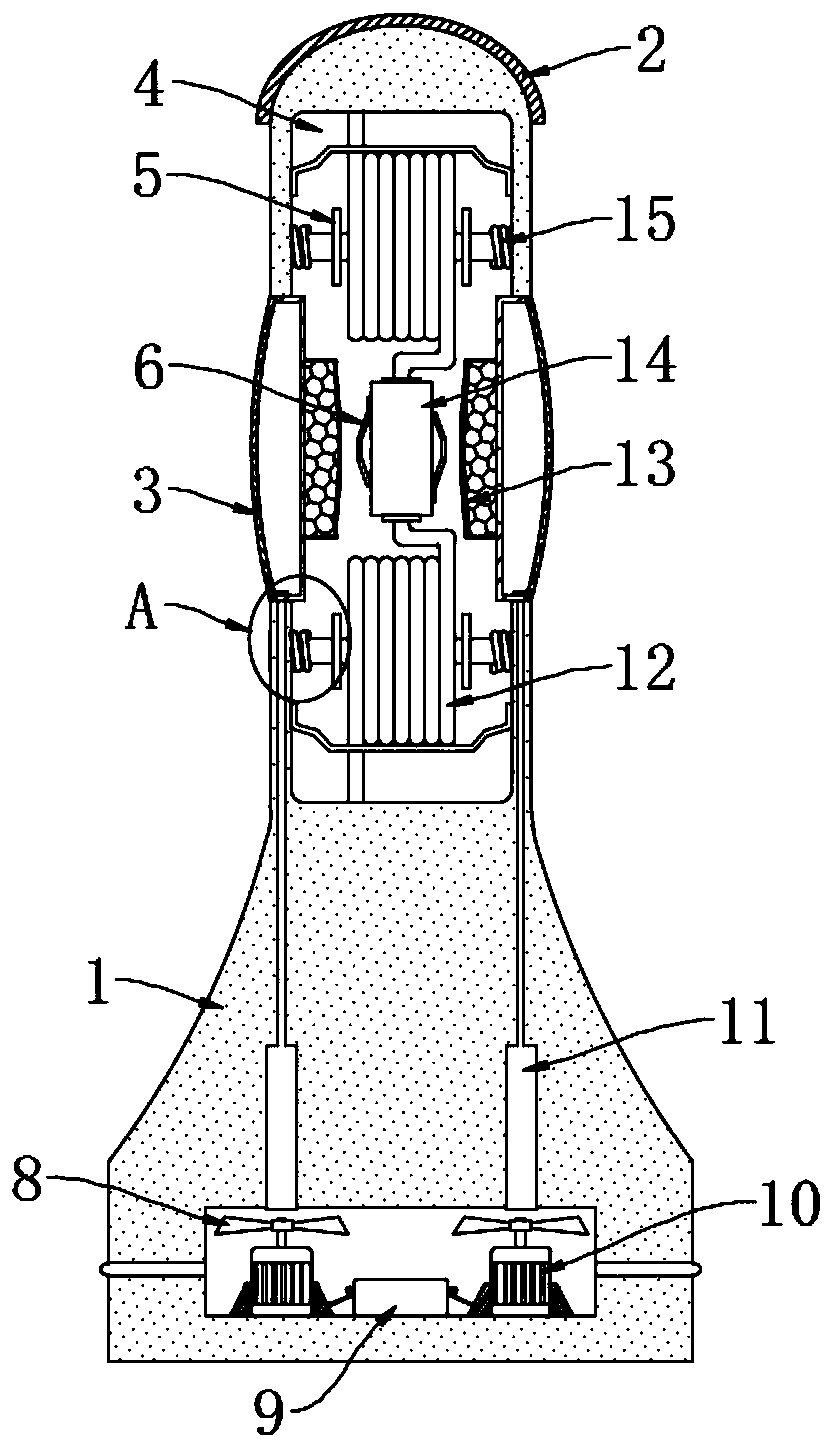

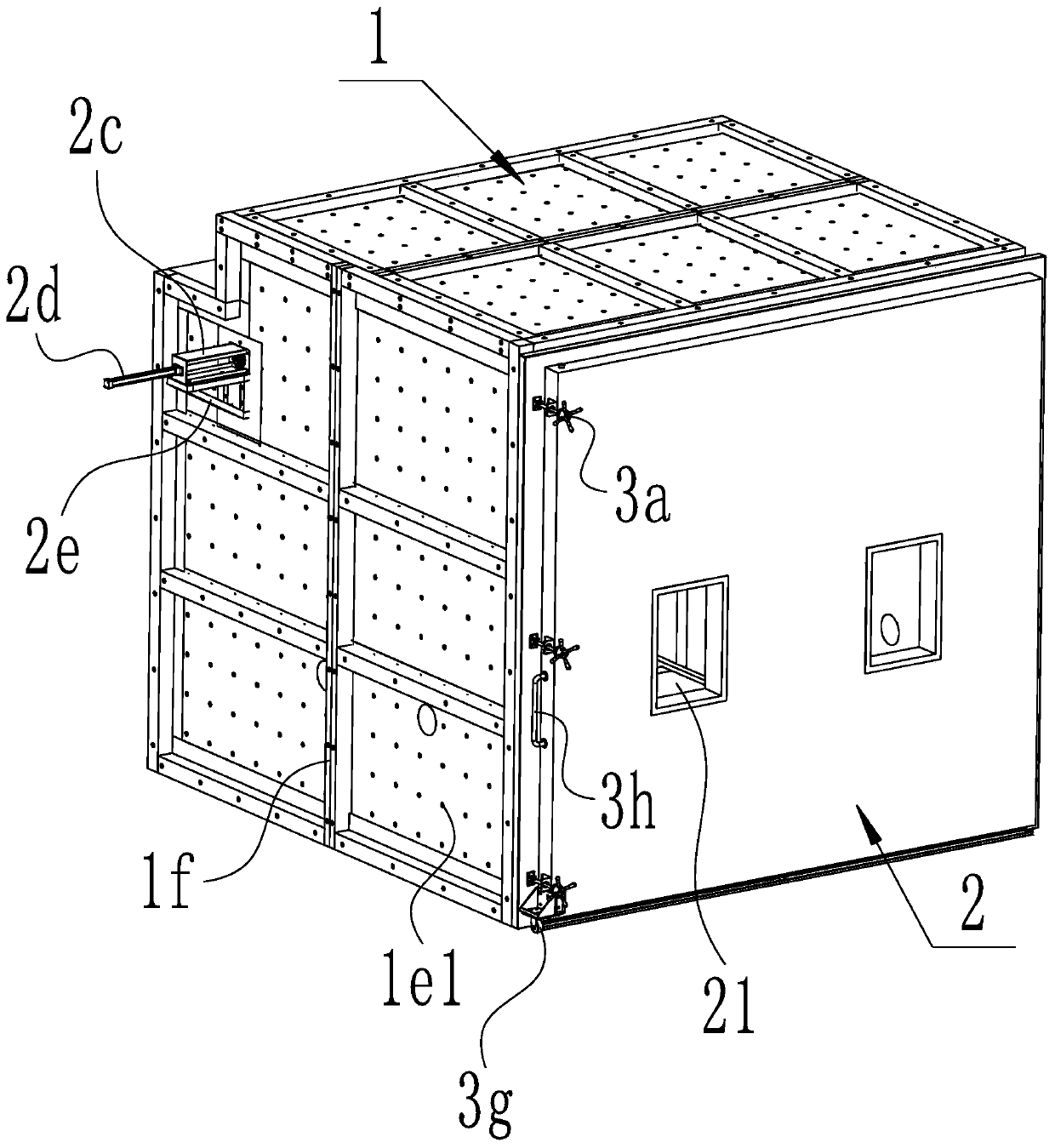

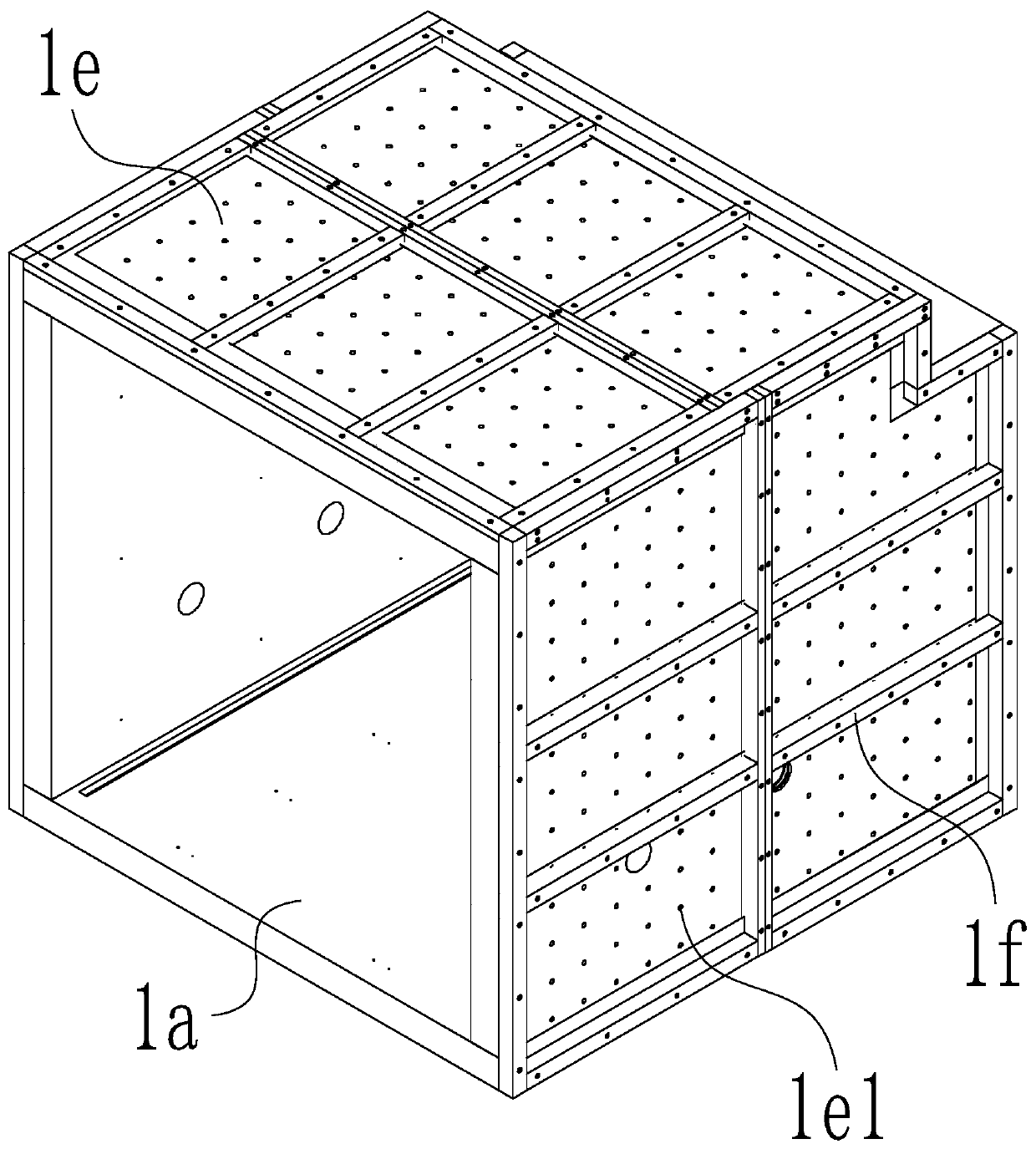

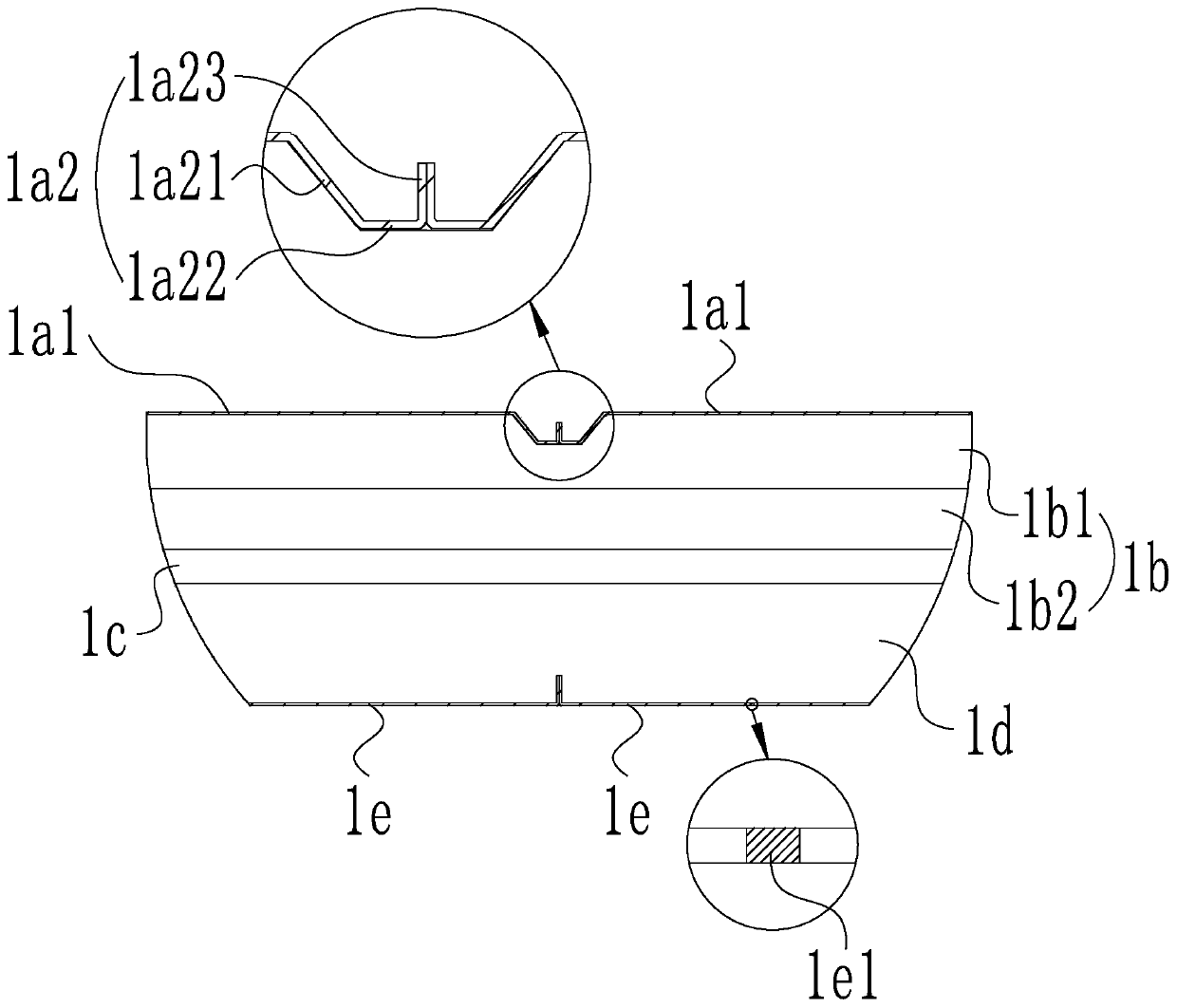

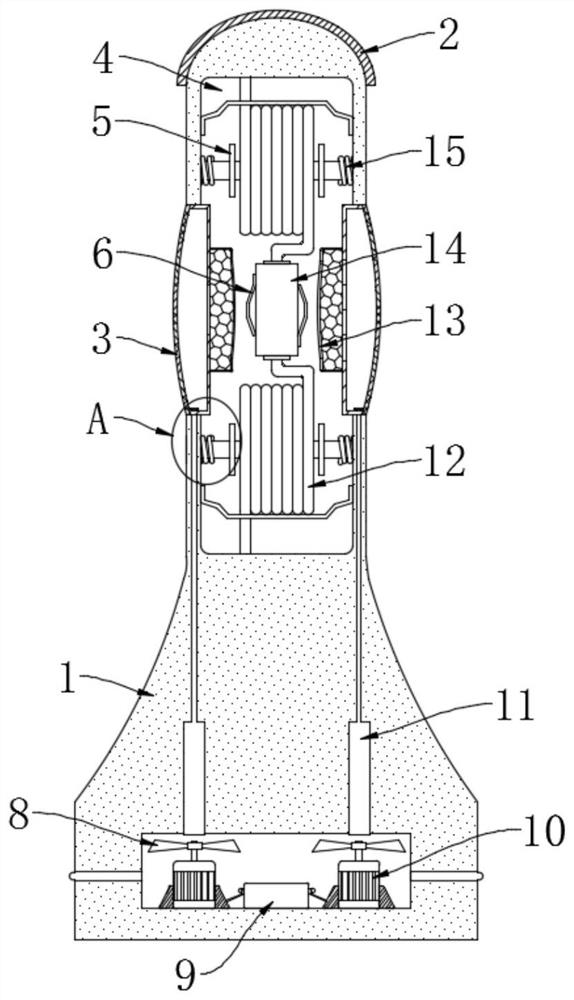

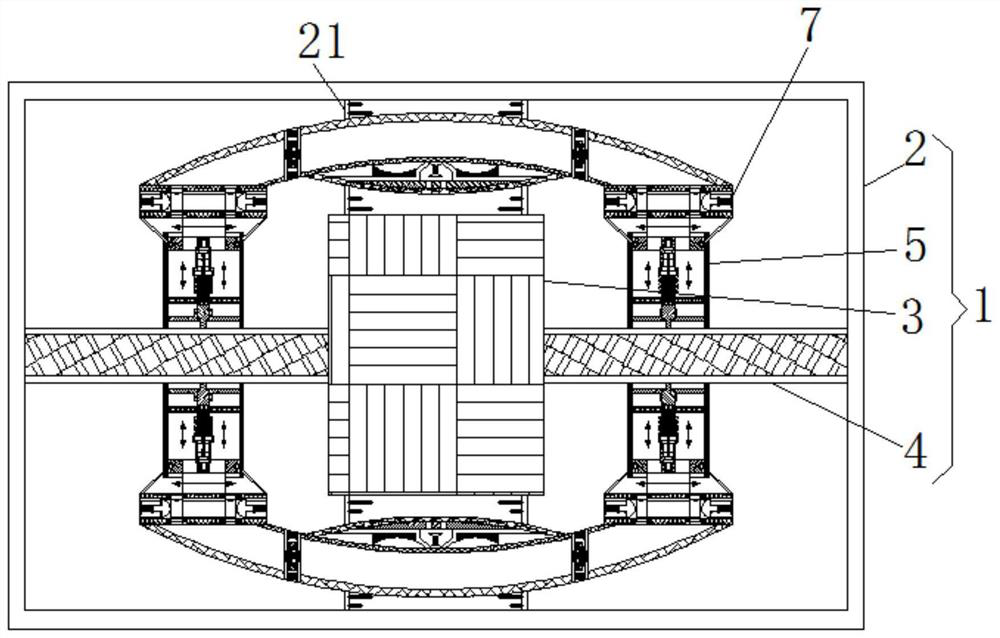

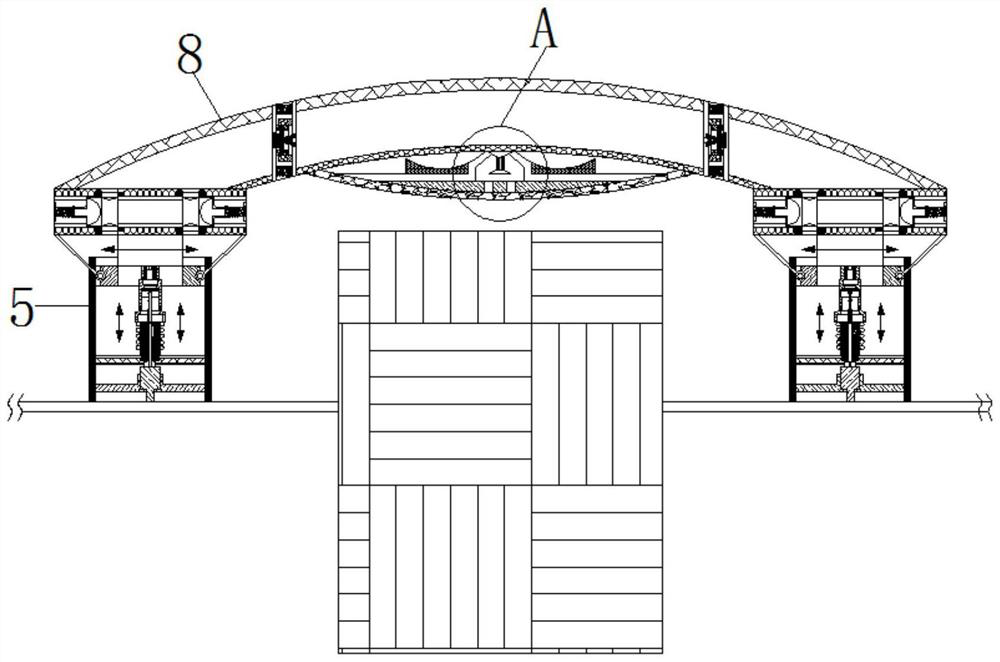

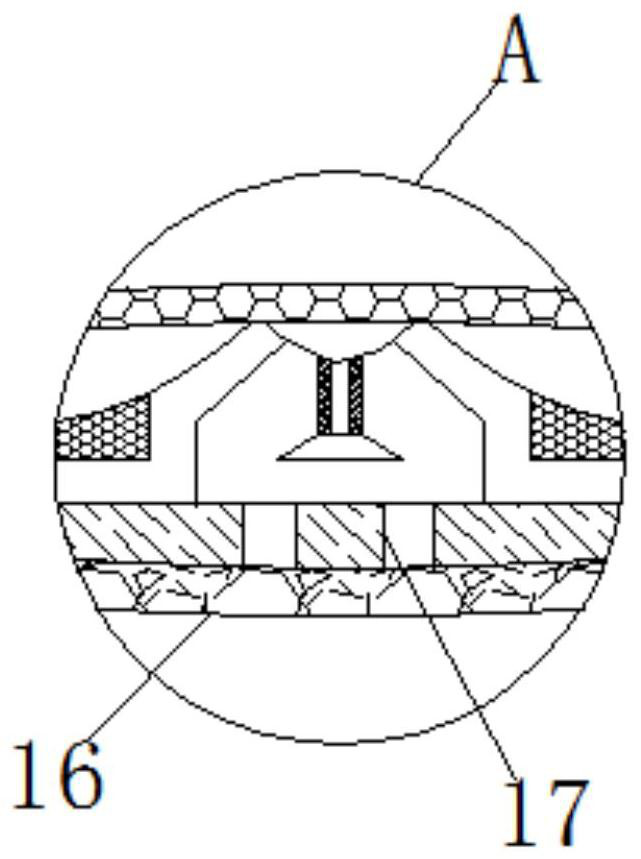

High-and-low-temperature alternating humidity and heat test chamber

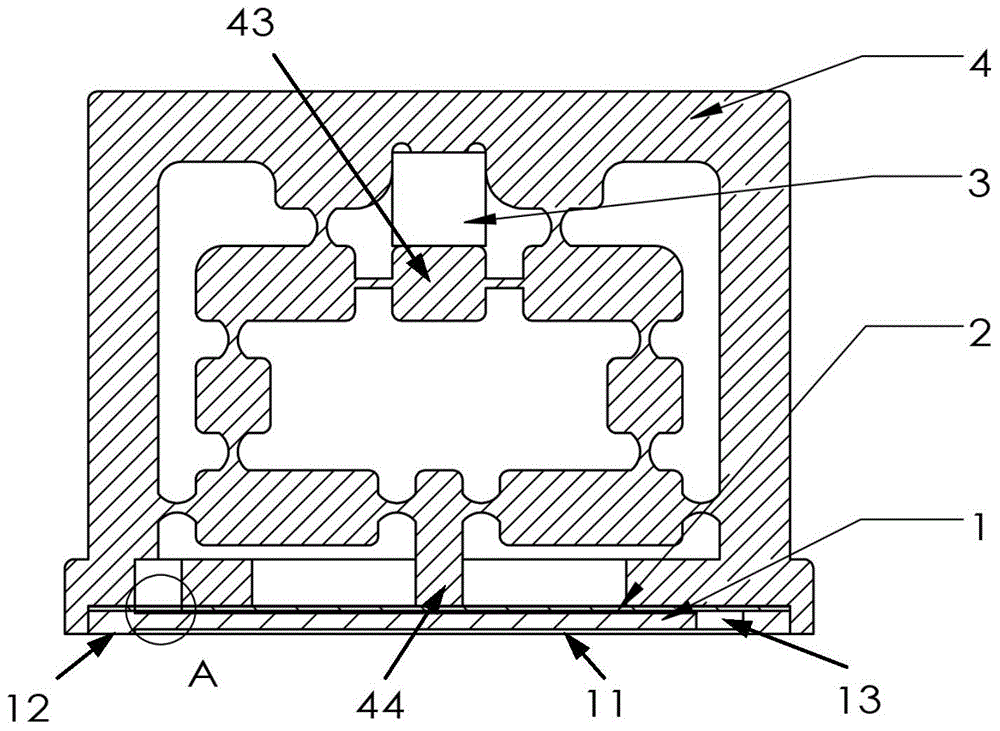

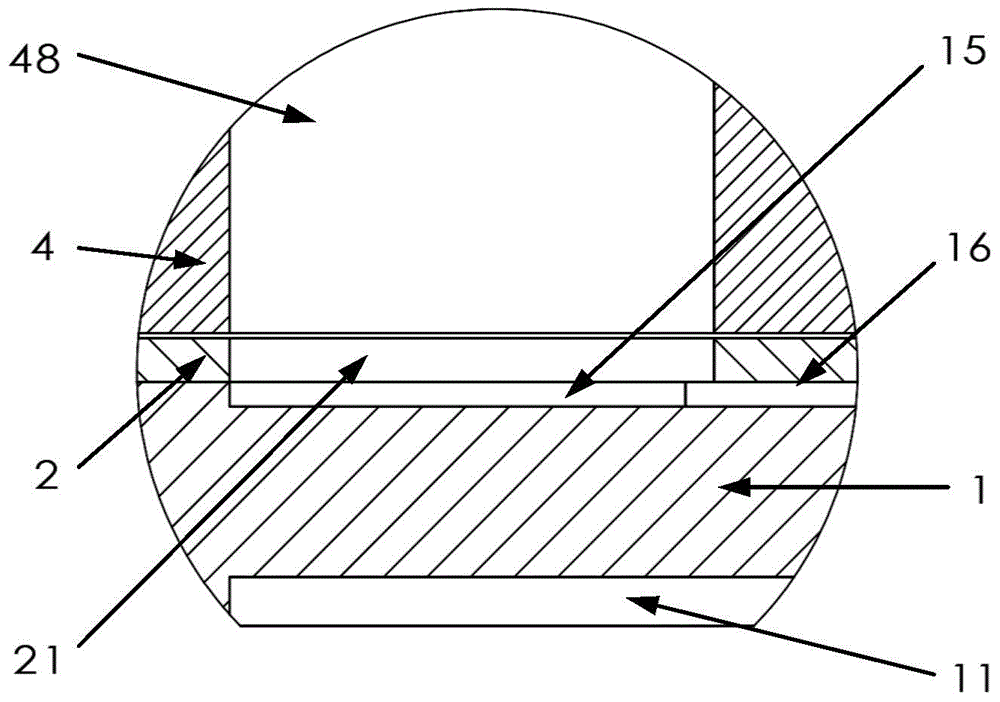

ActiveCN110394201AGuaranteed tightnessGuaranteed stabilityHeating or cooling apparatusEnclosures/chambersTest chamberEngineering

The invention discloses a high-and-low-temperature alternating humidity and heat test chamber. The high-and-low-temperature alternating humidity and heat test chamber comprises a box body, a box doorrotatably arranged at the opening side of the box body, and a heating mechanism, a refrigeration mechanism and a humidifying mechanism which are arranged in the box body, wherein the box body comprises an inner plate and an outer plate arranged at the outer side of the inner plate. By adoption of a technical scheme of the invention, the high-and-low-temperature alternating humidity and heat test chamber can be applicable to an ultralow-temperature environment with a temperature of lower than minus 100 DEG C and an ultrahigh-temperature environment with a temperature of 200 DEG C or higher, hasgood heat-preserving performance, is stable and reliable, does not generate large deformation, and guarantees stability of a box body structure and airtightness of the box body; when a humidity testis required, a humidity sensor located in the inner chamber of the box body can monitor the humidity of the inner chamber of the box body in real time; when an ultralow-temperature or ultrahigh-temperature test is about to be carried out, the humidity sensor is no longer located in the inner chamber of the box body and is effectively protected and avoided from being damaged; thus, stable operationof the high-and-low-temperature alternating humidity and heat test chamber is guaranteed.

Owner:重庆哈丁环境试验技术股份有限公司

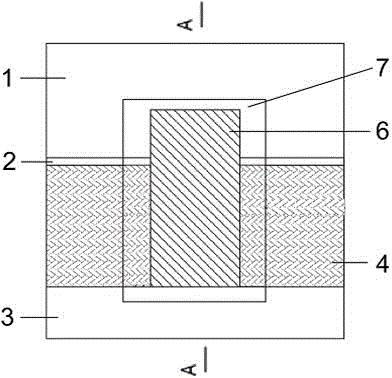

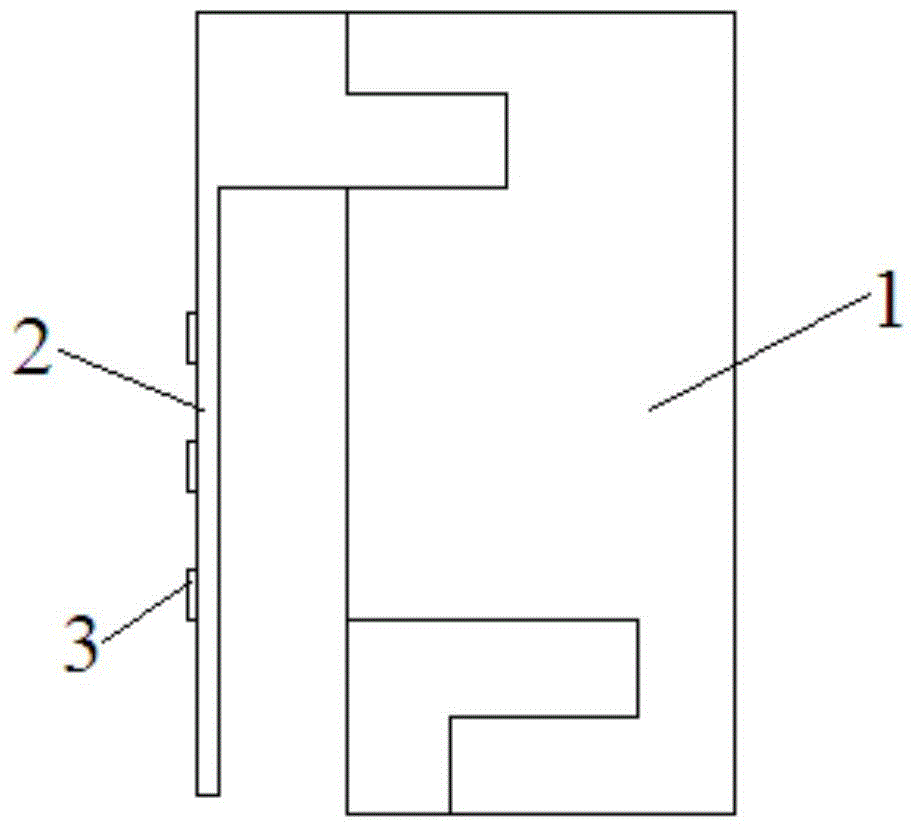

Floating type brake pad

PendingCN108644258AAvoid service lifeAvoid colliding with each otherBraking membersFriction liningFriction forceBrake pad

A floating type brake pad comprises a brake pad back plate, a friction body, a connection piece and an elastic supporting piece, wherein the brake pad back plate is provided with a facing plane and apositioning hole; the friction body comprises a friction part and a positioning part inserted into the positioning hole, and a first relative gap exists between the positioning part and the positioning hole; through the connection piece, the friction body is arranged on the brake pad back plate in a floating mode; and the elastic supporting piece is installed in the facing plane and connected withthe friction body, a guide hole suitable for allowing the positioning part to pass is formed in the elastic supporting piece, and the edge of the outline of the elastic supporting piece abuts againstthe inner side wall of the facing plane, or a second relative gap smaller than the first relative gap is formed between the edge of the outline of the elastic supporting piece and the inner side wallof the facing plane. The problems that an existing floating type brake pad is seriously deflected in the horizontal direction when being influenced by the action of brake friction force or vehicle vibration, thus, a friction body loses the best brake working surface, the brake effect is influenced, a connection piece connected with a brake pad back plate and the friction body is deformed and evenbroken due to shear force, the brake effect of the brake pad is reduced, and the service life of the brake pad is shortened are solved.

Owner:BEIJING TIANRENDAOHE NEW MATERIAL CO LTD

A hanging mobile socket

ActiveCN105048232BSimple structureReduce volumeCoupling contact membersTwo-part coupling devicesState of artElectrical conductor

Owner:SHANUTEC (SHANGHAI) CO LTD

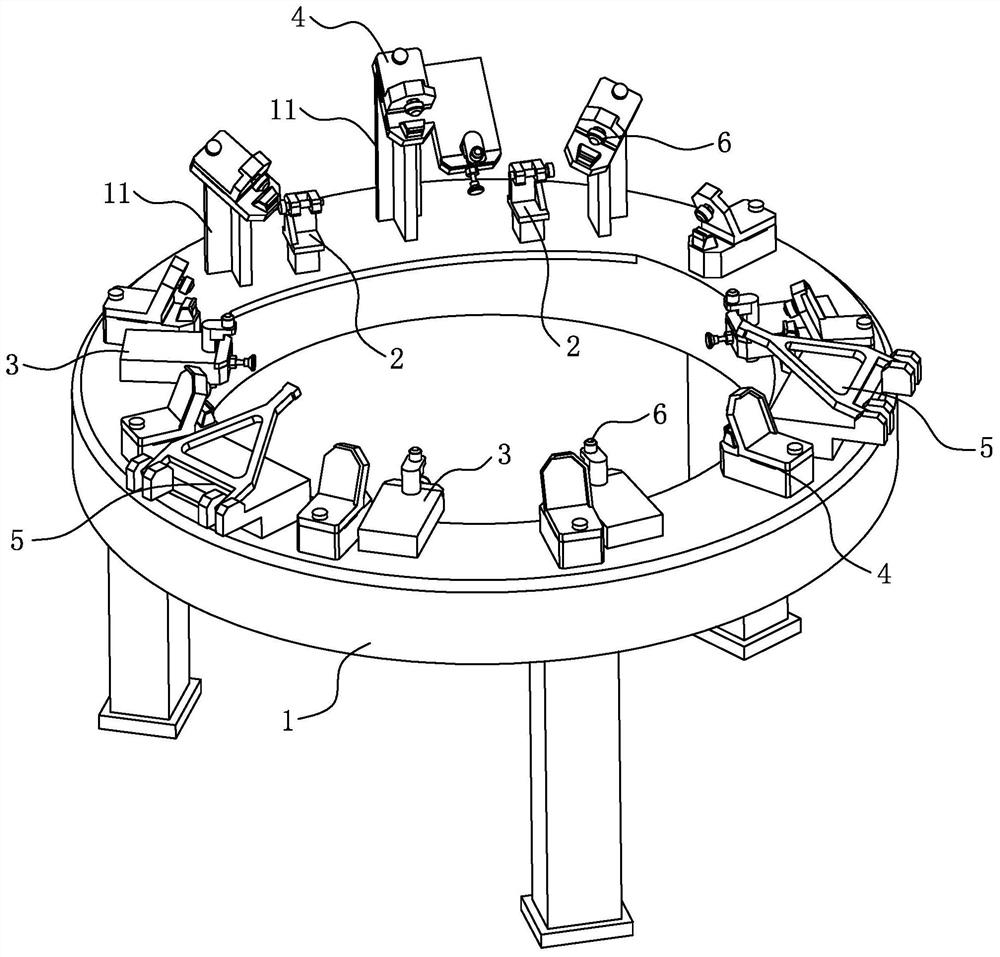

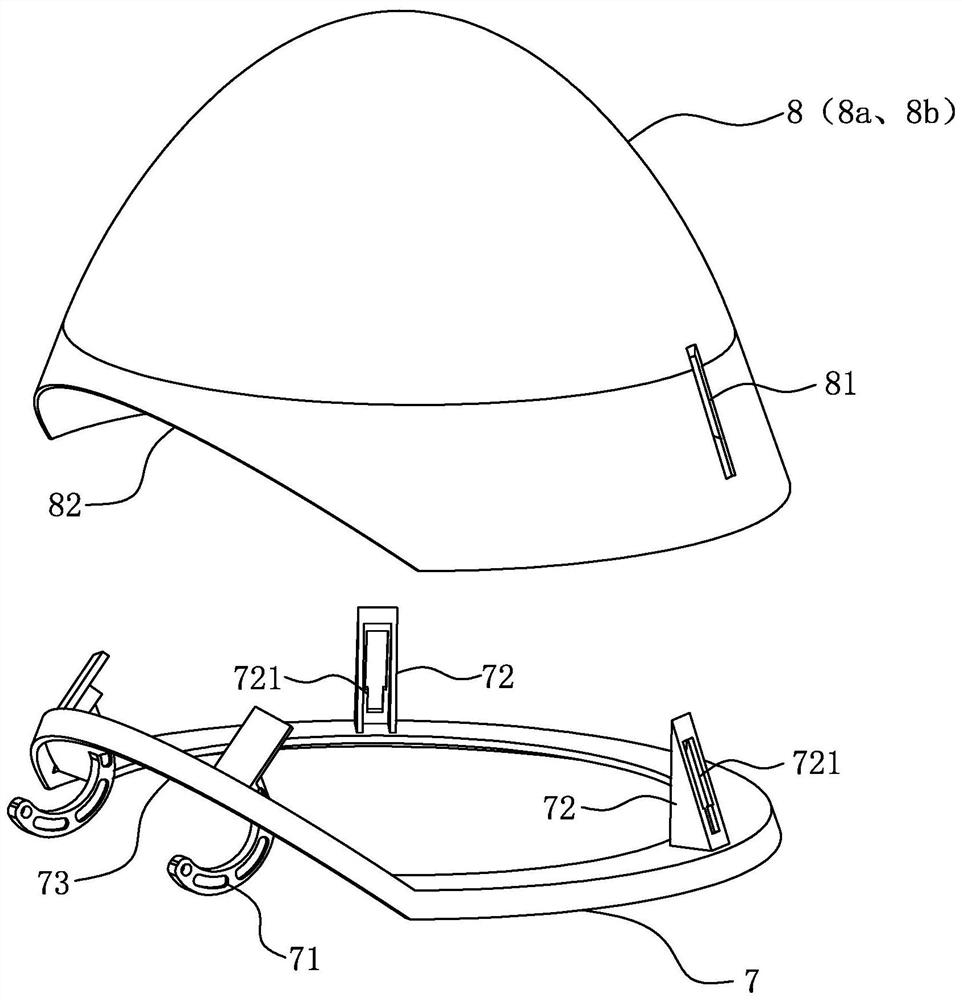

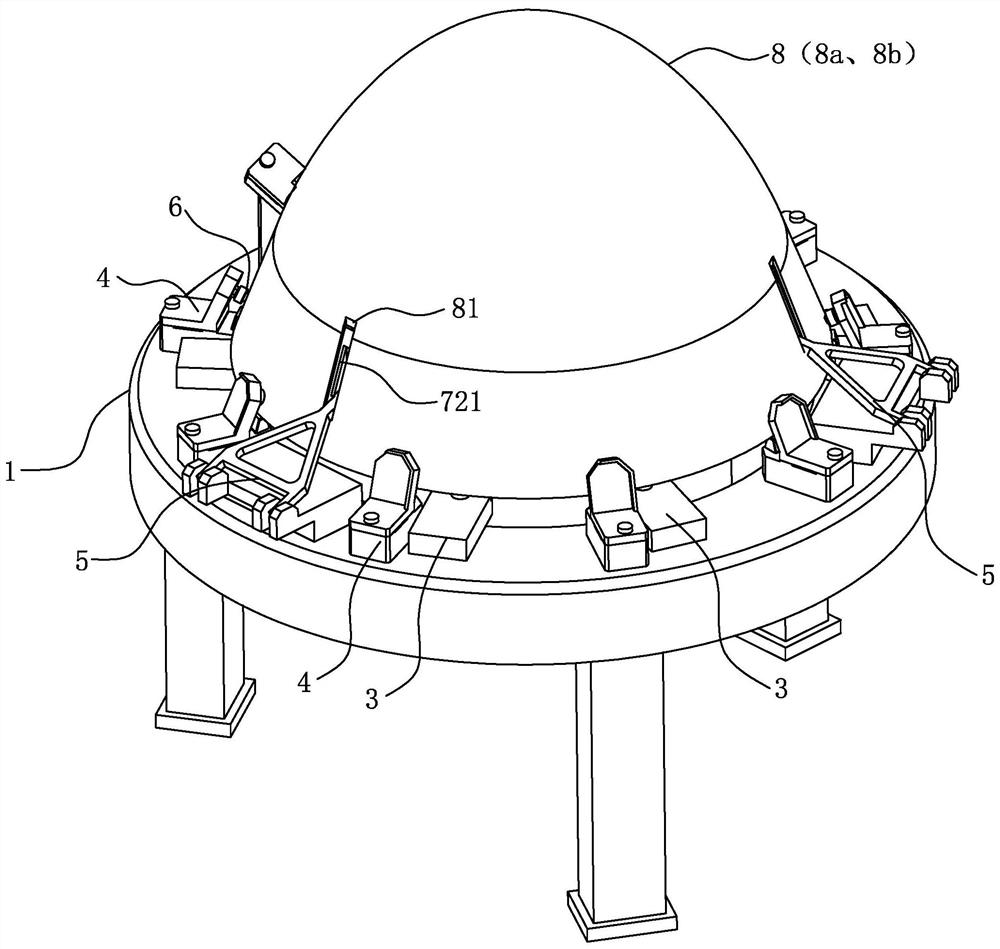

Radar cover shell replacement positioning detection method

PendingCN113829264AAvoid deformation damageThe installation position is accurateMeasurement devicesWork holdersBraced frameRadar

The invention relates to the technical field of aircraft radar cover maintenance, in particular to a radar cover shell replacement positioning detection method which comprises the steps of disassembling an original shell, installing a new shell and detecting the assembling precision of the new shell. When the original shell is demounted, all shell clamping mechanisms are used for clamping positioning, the original shell is in a position controlled state all the time, and the problem that due to the fact that bolts are demounted one by one, deformation and damage of a supporting frame are caused due to uneven stress between the original shell and the supporting frame is avoided; when the new shell is installed, the shell clamping mechanisms are used for clamping positioning, the position of the new shell is always kept at an accurate position, and it is guaranteed that the installation position of a locking screw is accurate; After side pressing pieces and cushion blocks of the shell clamping mechanisms are detached, remaining supporting protruding blocks become a measuring basis, whether installation of the new shell meets the requirement or not can be judged by measuring the distance between the edge of the new shell and the top faces of the supporting protruding blocks and comparing the distance with a design manual, the measuring process is simple, and efficiency is high.

Owner:晋江太古飞机复合材料有限公司

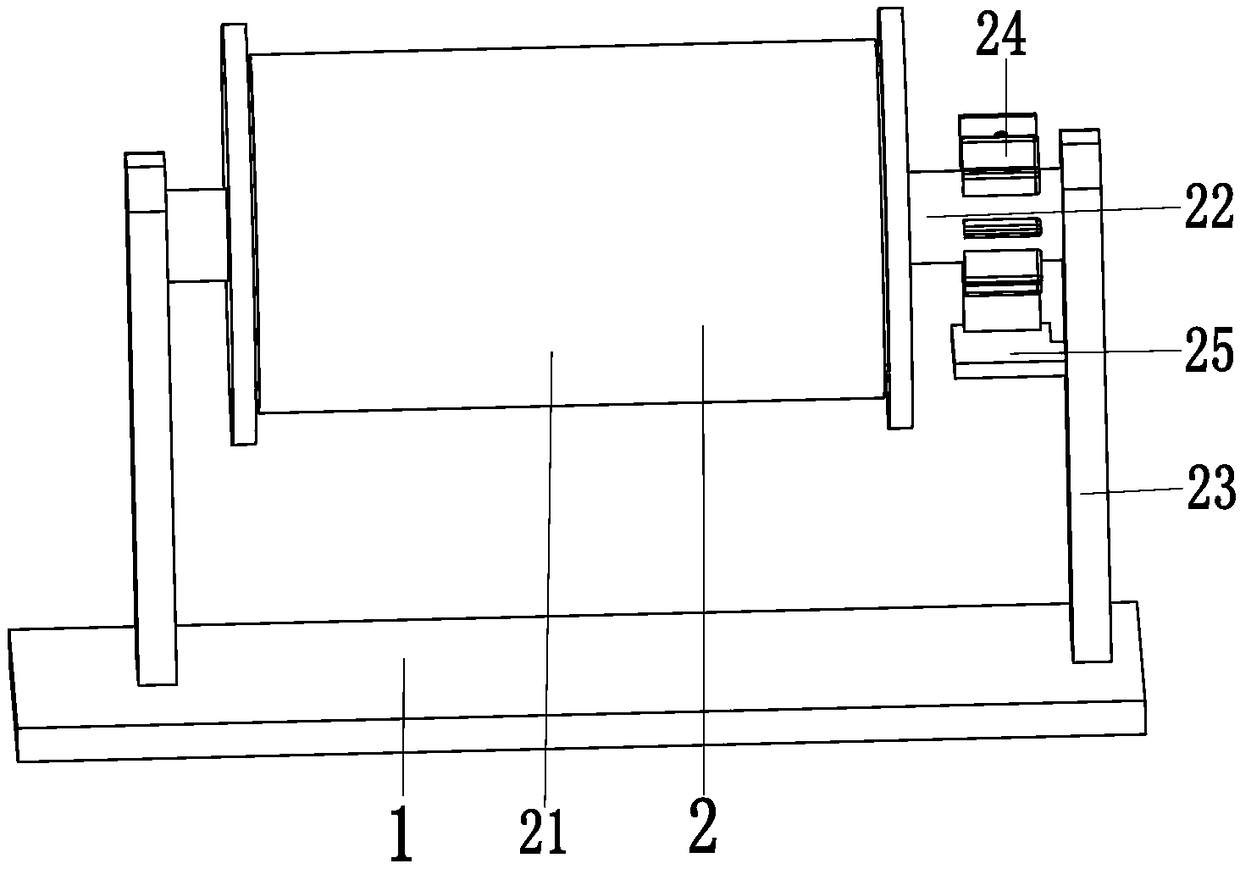

Sponge slicing method and sponge slicing fixing device for automobile cushion

The invention discloses a sponge slicing method for an automobile cushion. The sponge slicing method comprises a longitudinal cutting step and a transversal cutting step, wherein during longitudinal cutting, sponge is longitudinally flattened, and then the longitudinal cutting is carried out on the sponge in the flattened state by virtue of a cutting device; and during transversal cutting, the sponge is inflated by virtue of an inflator, and the transversal cutting is carried out on the sponge by virtue of a cutting device. According to the sponge slicing method disclosed by the invention, during the longitudinal cutting, a piston is pressed by a hydraulic cylinder to flatten the sponge to be cut in a compression barrel, and then the cutting is carried out, so that the displacement and the deformation of the sponge generated during the cutting process can be avoided; during the transversal cutting, a rubber film is arranged on the sponge to be cut in a sleeving manner by virtue of an elastic band, a connection valve is opened, the inflator inflates the sponge, at this moment, the sponge has a certain hardness due to inflation inside and cannot generate large-amplitude deformation during the cutting, and a fixing plate is extruded by a spring to be abutted against the sponge to further realizing fixing; and the two manners improve the cutting accuracy of the sponge.

Owner:南通斯麦汽车内饰材料有限公司

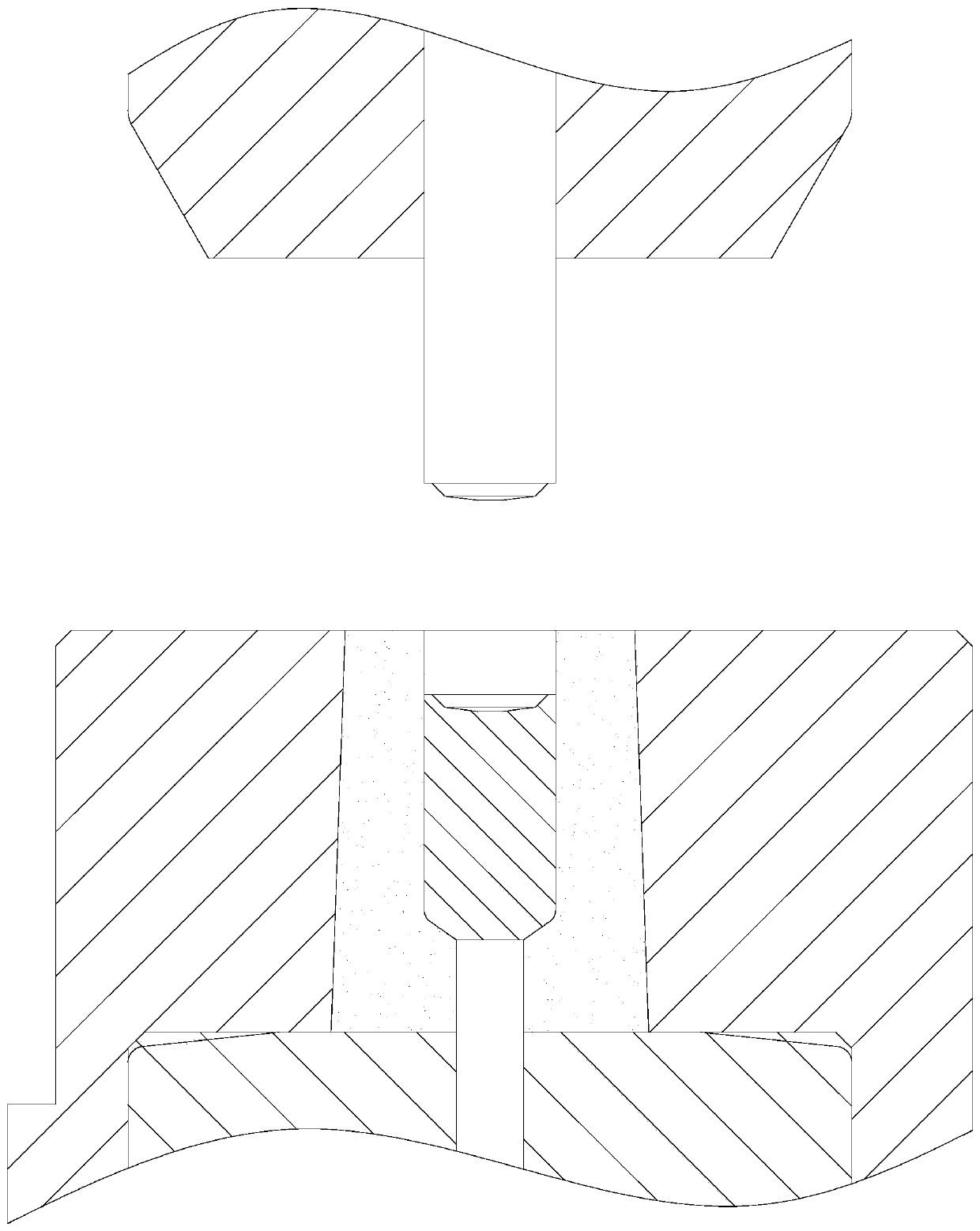

Annular thin-wall part forming method, forming mold and forming stamping tool

ActiveCN110576132AForming resistance is smallReduce production energy consumptionForging/hammering/pressing machinesThin walledMaterials science

The invention discloses an annular thin-wall part forming method. The forming method is applied to a columnar blank material, and comprises the following steps of head part upsetting, hole extruding and thin-wall part extruding, wherein upsetting is conducted on one end of an initial blank material section to form a head part, the initial blank material section forms a stepped shaft-shaped blank material section, and hole upsetting is simultaneously conducted on the end surface of one end of the initial blank material section in the process of initial blank material section upsetting, so thatan initial positioning hole is formed in the end surface in the head part upsetting step; the initial positioning hole is extruded and stretched, so that the axial dimension of the stepped shaft-shaped blank material section becomes larger, in addition, the initial positioning hole becomes longer and forms a long positioning hole, and the axial dimension of the head part becomes larger, wherein the to-be-deformed volume required by a subsequently formed thin-wall part is reserved in the head part in the hole extruding step; and a circumferential surface part of the head part is extruded, so that a thin-wall part is formed for the head part in the thin-wall part extruding step. Due to the fact that the forming resistance of the forming method is small, the impact force borne by a cold unsetting mold is correspondingly small.

Owner:顺科智连技术股份有限公司

Manufacture method of automobile floor mat

PendingCN108394330ADeformation will notDeformation will not occurVehicle arrangementsCivil engineering

The invention provides a manufacture method of an automobile floor mat, comprising: measuring floor mat positional dimensions of an automobile seat portion to obtain automobile floor mat dimensions; cutting all bottom shell units and face layer units of the automobile floor mat according to the automobile floor mat dimensions; splicing all the bottom shell units, and sewing to form a floor mat bottom shell; splicing all the face layer units, and sewing to form the floor mat face layer; stacking the floor mat face layer on the floor mat bottom shell, and allowing the upper surface of the floormat bottom shell to contact the lower surface of the floor mat face layer; pasting the floor mat face layer and the floor mat bottom shell to obtain the automobile floor mat. The floor mat bottom shell is formed by splicing the bottom shell units, so that producing dies to perform impacting is not required, considering re-manufacture of dies for updating of vehicles is not required either, and diewaste is avoided.

Owner:合肥慕尚车品科技有限公司

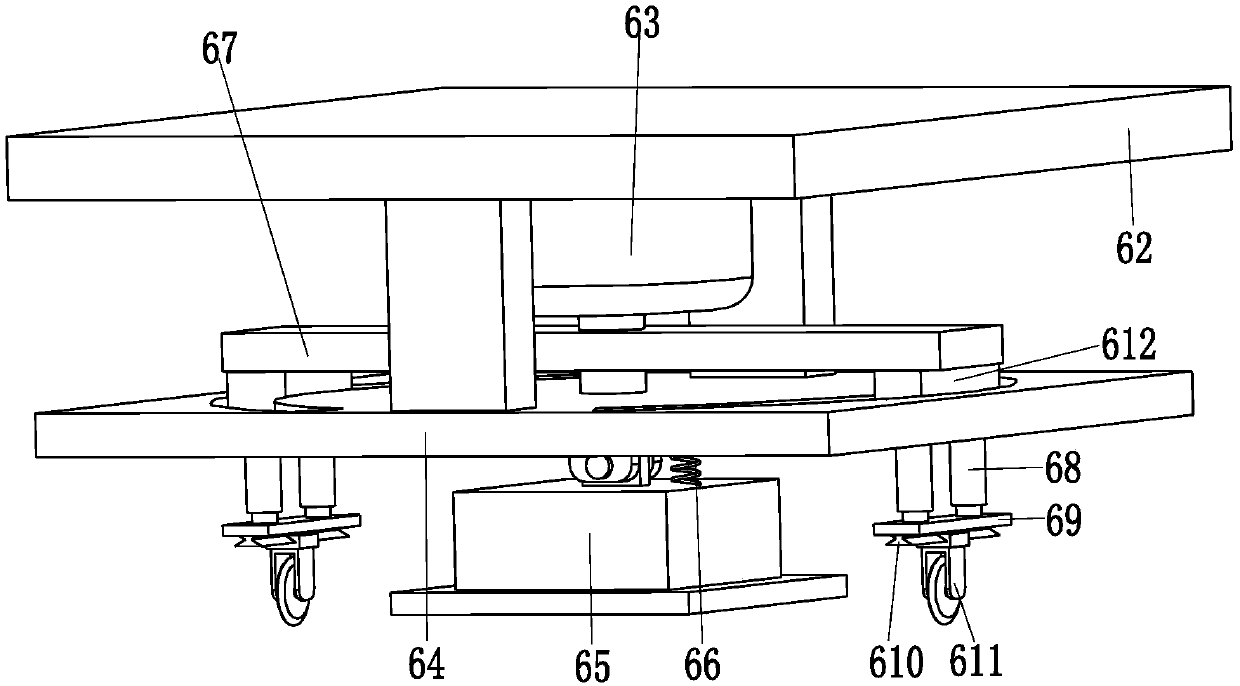

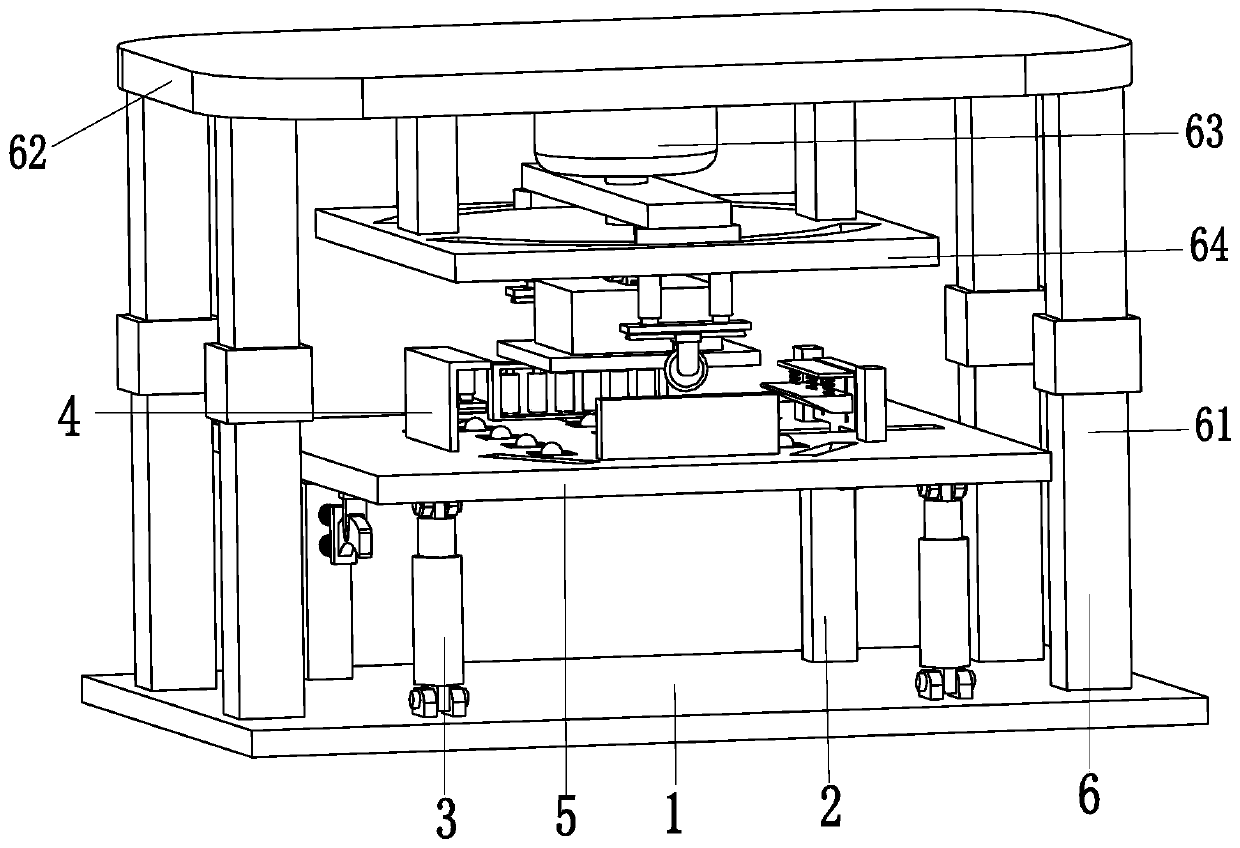

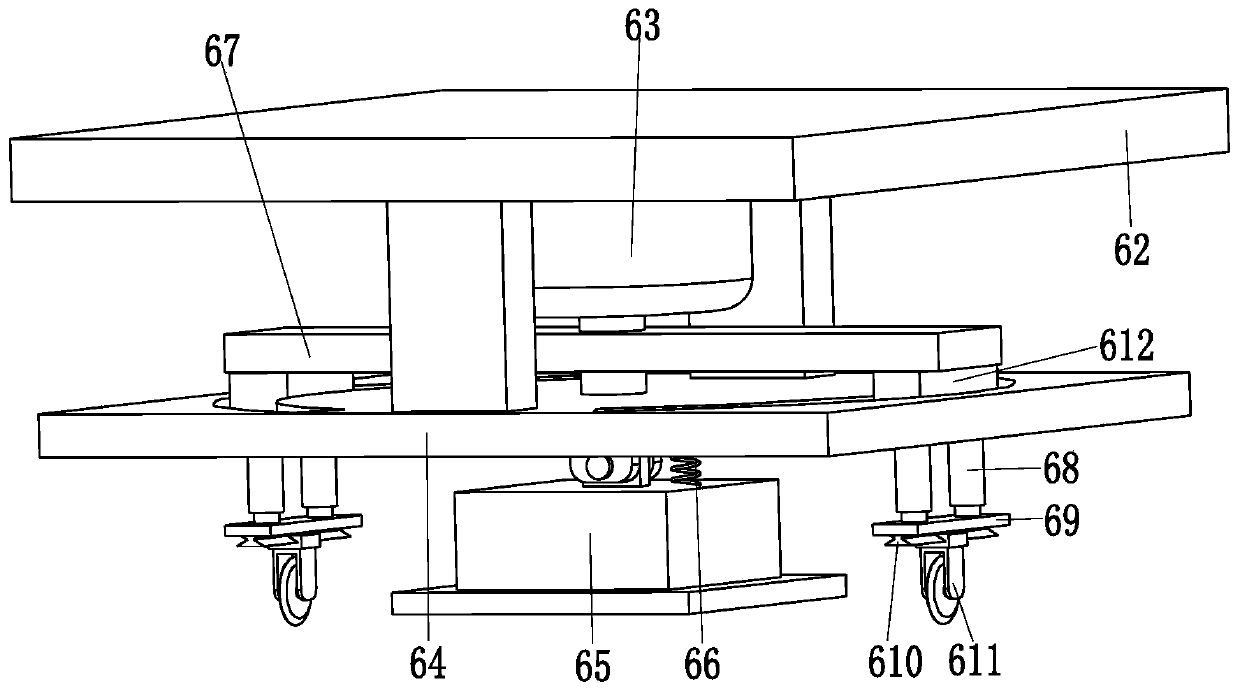

A punching machine for aluminum-plastic film for soft-pack lithium battery outer packaging

ActiveCN109176723BDeformation will not occurImprove stamping effectSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsHydraulic cylinderStructural engineering

The invention relates to a punching machine for aluminum-plastic film for the outer packaging of a soft-packed lithium battery, comprising a supporting base plate and a punching device, the punching device is installed on the top of the supporting base plate; the punching device includes a punching frame, a supporting hydraulic cylinder , supporting mobile body, supporting telescopic body, telescopic body spring, lateral branch chain, rolling branch chain, stamping hydraulic cylinder, stamping mechanism, mobile body connection block, mobile body push rod, push rod connection frame and stamping bracket; The rolling branch chain includes a rolling electric slider, a rolling push rod, a rolling connecting frame, a rolling shaft, a rolling wheel, a telescopic wheel and a rolling spring. The present invention can solve the problem that the stamping die existing in the stamping of the aluminum-plastic film of the outer packaging of the soft-packed lithium battery cannot be adjusted, the position around the aluminum-plastic film will be deformed when the aluminum-plastic film is stamped, and the stamping effect of the aluminum-plastic film is poor. Wait for the problem.

Owner:重庆斯托赛克塑业有限责任公司

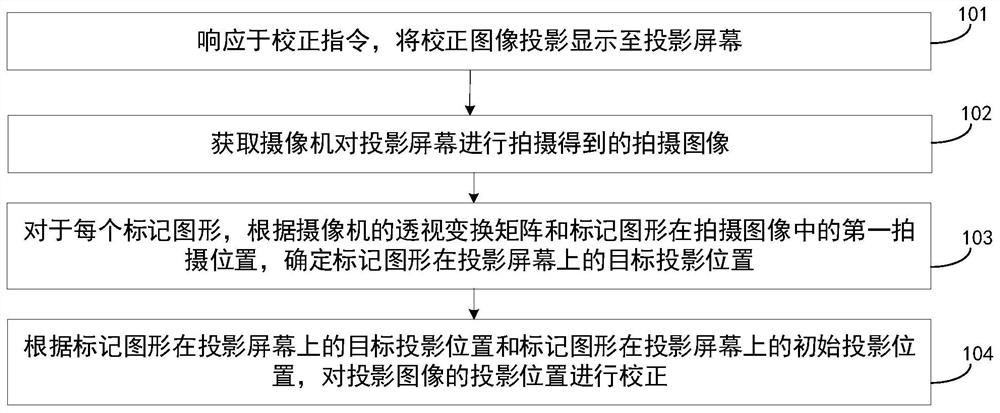

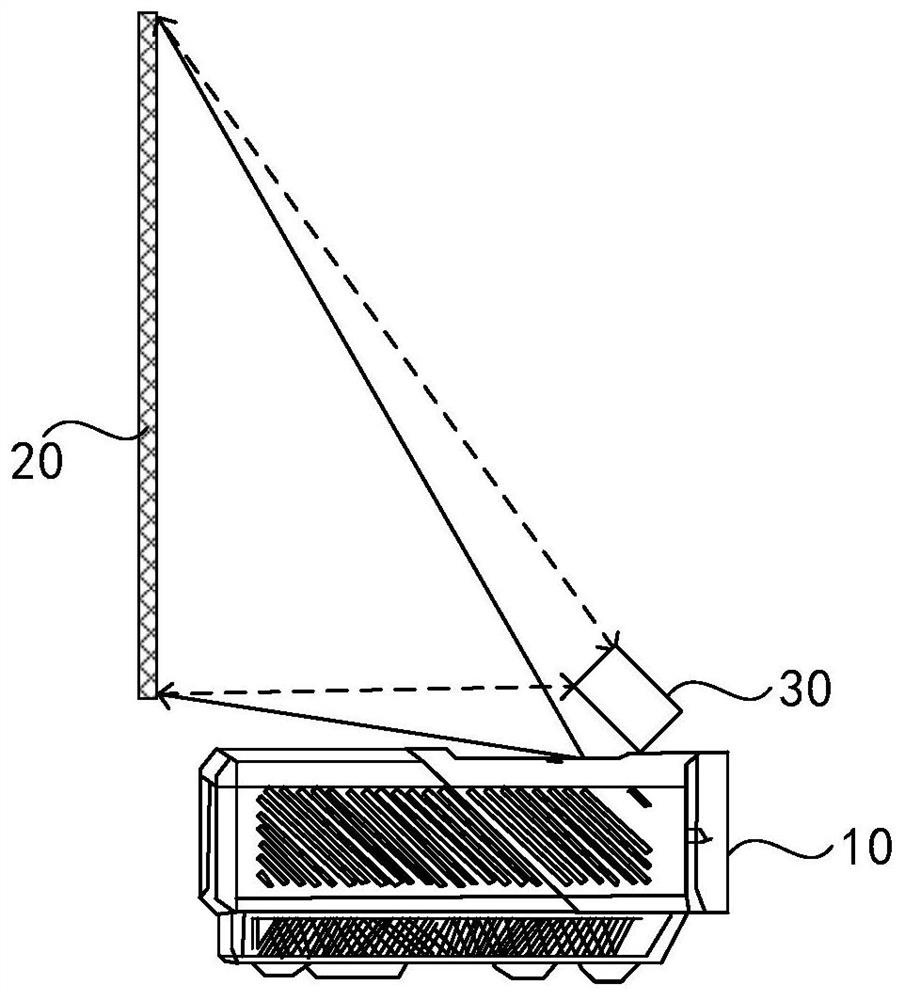

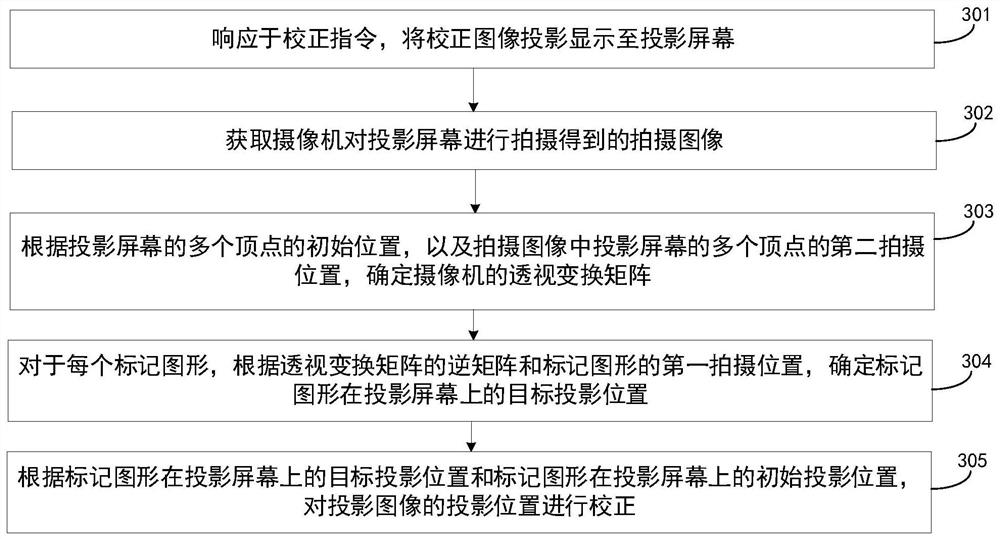

Projection image correction method and laser projection equipment

PendingCN114765680ADeformation will not occurImprove the display effectPicture reproducers using projection devicesGraphicsProjection image

The invention discloses a projected image correction method and laser projection equipment, and belongs to the field of projection display. The laser projection device can determine the target projection position of the marked graph on the projection screen according to the perspective transformation matrix and the first shooting position of each marked graph in the shot image. Afterwards, the laser projection device can correct the projection position of the projection image according to the target projection position of the marked graph and the initial projection position of the marked graph, thereby ensuring that the projection image displayed on the deformed projection screen does not deform, and ensuring that the display effect of the projection image is relatively good.

Owner:QINGDAO HISENSE LASER DISPLAY CO LTD

A sheet metal automatic precision shearing system

ActiveCN109604703BStable position adjustmentDeformation will not occurShearing machinesShearing machine accessoriesHydraulic cylinderClassical mechanics

The invention relates to an automatic plate material finely cutting system. The automatic plate material finely cutting system comprises a supporting bottom plate, supporting columns, angle hydrauliccylinders, a positioning device, a positioning supporting plate, and cutting devices. The supporting columns are mounted on the top of the rear end of the supporting bottom plate. The rear end of thepositioning supporting plate is mounted on the tops of the supporting columns by hinges. The angle hydraulic cylinders are arranged at the bottom of the front end of the positioning supporting plate.The angle hydraulic cylinders are mounted between the supporting bottom plate and the positioning supporting plate by hinges. Cutting grooves are symmetrically formed in the outer end of the positioning supporting plate. The positioning device is mounted on the positioning supporting plate. The cutting devices are located at the upper end of the positioning supporting plate. The cutting devices are mounted on the top of the outer end of the supporting bottom plate. The automatic plate material finely cutting system can solve the problems that when corners of existing steel plates are cut, thesteel plates with different sizes can not be positioned, steel plate position adjusting is not smooth, steel plate cutting with different cutting edge inclinations can not be achieved, and the steel plates deform during cutting.

Owner:杭州宝伟汽车零部件有限公司

A solar panel device with functions of snow removal and protection

ActiveCN112511098BExtended service lifeAvoid the phenomenon of large-scale snow accumulationPhotovoltaicsPhotovoltaic energy generationSnow removalSnowpack

The present invention relates to the technical field of solar panels, in particular to a solar panel device with snow removal and protection functions, including a device body, the device body includes two first housings and solar panels, and the solar panels are fixed on two Between the two first housings, the upper half of the opposite side of the first housing is provided with an inlet and outlet; a shielding mechanism is also included, and the shielding mechanism includes two first fixing rods, four first gears, Two chains, moving components and several snow removal components, the first fixing rod is located inside the corresponding first housing, and both ends of the first fixing rod are fixed to the opposite sides of the inner wall of the first housing The two first gears are symmetrically rotatably sleeved on the outer peripheral surface corresponding to the first fixing rod, and several of the snow removal assemblies cover the solar panels. The invention has the effect of avoiding the possibility of the solar panel being compacted by snow and prolonging the service life of the solar panel.

Owner:柏拉图(上海)电力有限公司

A kind of aluminum-plastic film stamping equipment for soft-pack lithium battery and its stamping process

ActiveCN109176692BWrinkling does not occurImprove cutting effectSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringStructural engineering

Owner:赣州诺威新能源有限公司

A road barrier for buffer warning

InactiveCN110924333BOvercoming deformation forceMove quicklyMachines/enginesTraffic signalsPost collisionAccidents vehicle

The invention discloses a road isolation barrier for buffer warning, which includes an isolation pile, a warning light is installed on the top of the isolation pile, two square grooves are symmetrically opened on the side wall of the isolation pile and an air bag is glued on the side wall of the isolation pile. An induction chamber is provided in the isolation pile, and the induction chamber communicates with two square slots. A storage box is fixedly installed on the side of each square slot close to the induction chamber, and a circuit box is fixedly installed in the middle of the induction chamber. The invention transforms the rigid collision between the vehicle and the isolation pile into the elastic collision between the vehicle and the airbag when an accident occurs, thereby reducing the impact force between the two, increasing the buffering of the vehicle, thereby improving the protective effect of the isolation pile, and can also Avoid serious damage to the isolation pile; after a collision, the warning light on the isolation pile will automatically light up and last for a certain period of time, thereby reminding other drivers to avoid the accident vehicle in time and reduce the occurrence of serial accidents and rear-end collisions.

Owner:商河园通市政工程有限公司

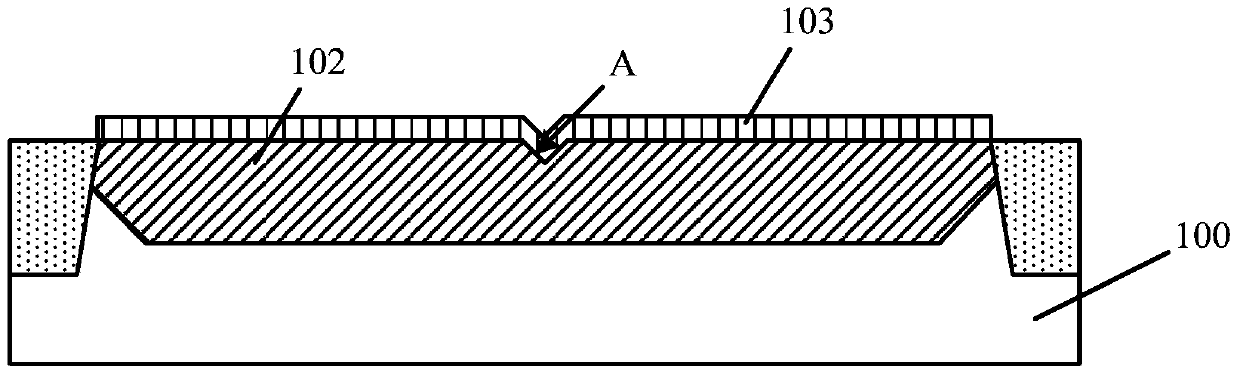

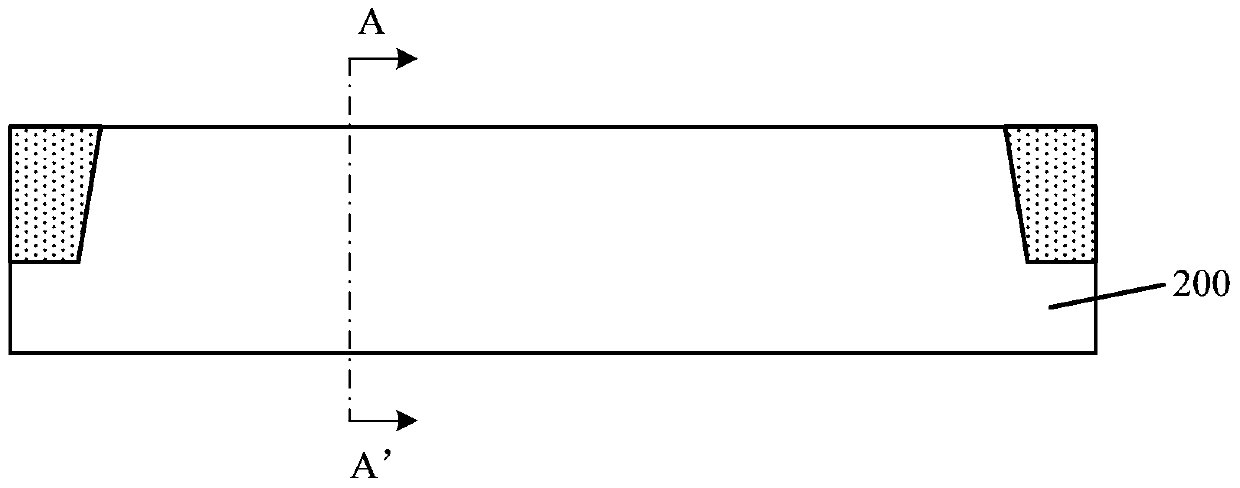

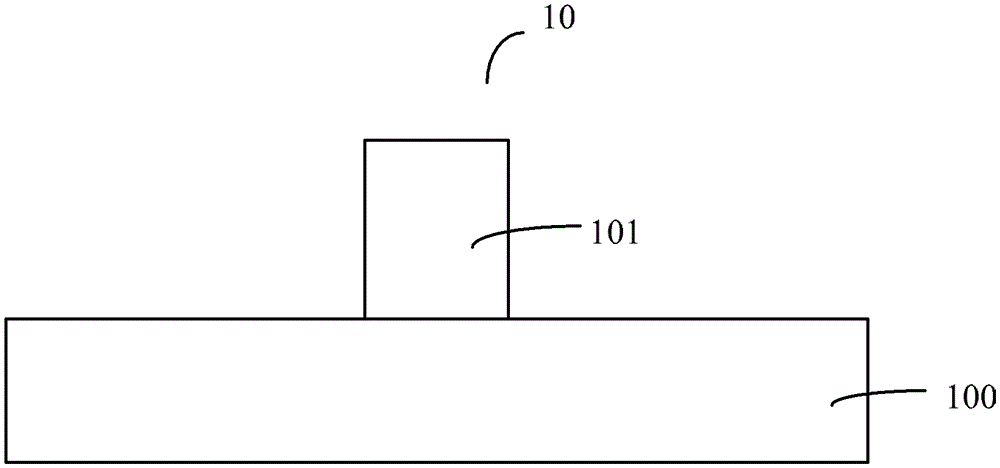

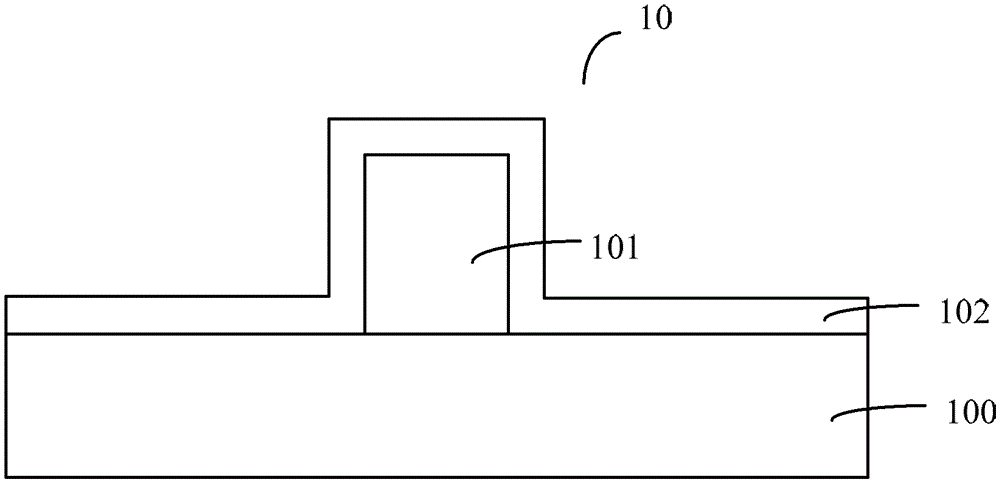

Formation method of semiconductor structure

ActiveCN106158654BInhibition of recrystallizationNot easy to cause deformationSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsSemiconductor structure

The invention provides a semiconductor structure forming method. The method comprises the steps of providing a substrate; forming an opening in the substrate; forming a stress layer in the opening; forming an initial covering layer on the surface of the substrate and the surface of the stress layer, wherein the material of the initial covering layer is composed of an amorphous semiconductor material; converting the part of the initial covering layer, that is positioned on the surface of the stress layer, into a covering layer through the crystallization process, wherein the material of the covering layer is composed of a crystalline semiconductor material; and removing the initial covering layer that is not converted into the covering layer after the crystallization process. The formed semiconductor structure is good in morphology and stable in performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Energy-saving and environment-friendly triode used in automatic temperature measurement circuit structure

PendingCN114061772ADeformation will not occurAvoid misjudgmentThermometer detailsEmergency treatmentFire - disasters

The invention relates to the technical field of triode circuit structure protection, and discloses an energy-saving and environment-friendly triode used in an automatic temperature measurement circuit structure, which is characterized in that the energy-saving and environment-friendly triode comprises a detection mechanism, the detection mechanism comprises a shell, and the inner surface of the shell is fixedly connected with a tube body; circuit structures are fixedly connected to the left side and the right side of the tube body correspondingly, guide rails are fixedly connected to the upper sides and the lower sides of the circuit structures correspondingly, and sliding plates are slidably connected to the surfaces of the guide rails in the vertical direction. When the triode expands, the two sides of the elastic plate are driven to expand in the direction close to the shell, when the two sides of the elastic plate expand, the center position of the elastic plate drives a flame-retardant plate to be close to the tube body, and when the flame-retardant plate makes contact with the tube body, according to the interaction of force, a flame retardant can be extruded to be sprayed to the surface of the pipe body from the center of a folding plate; and the phenomenon that the pipe body is damaged due to too high temperature and a fire disaster occurs is avoided, so that the effect of emergency treatment to avoid the fire disaster when the situation occurs is achieved.

Owner:深圳市昌豪微电子有限公司

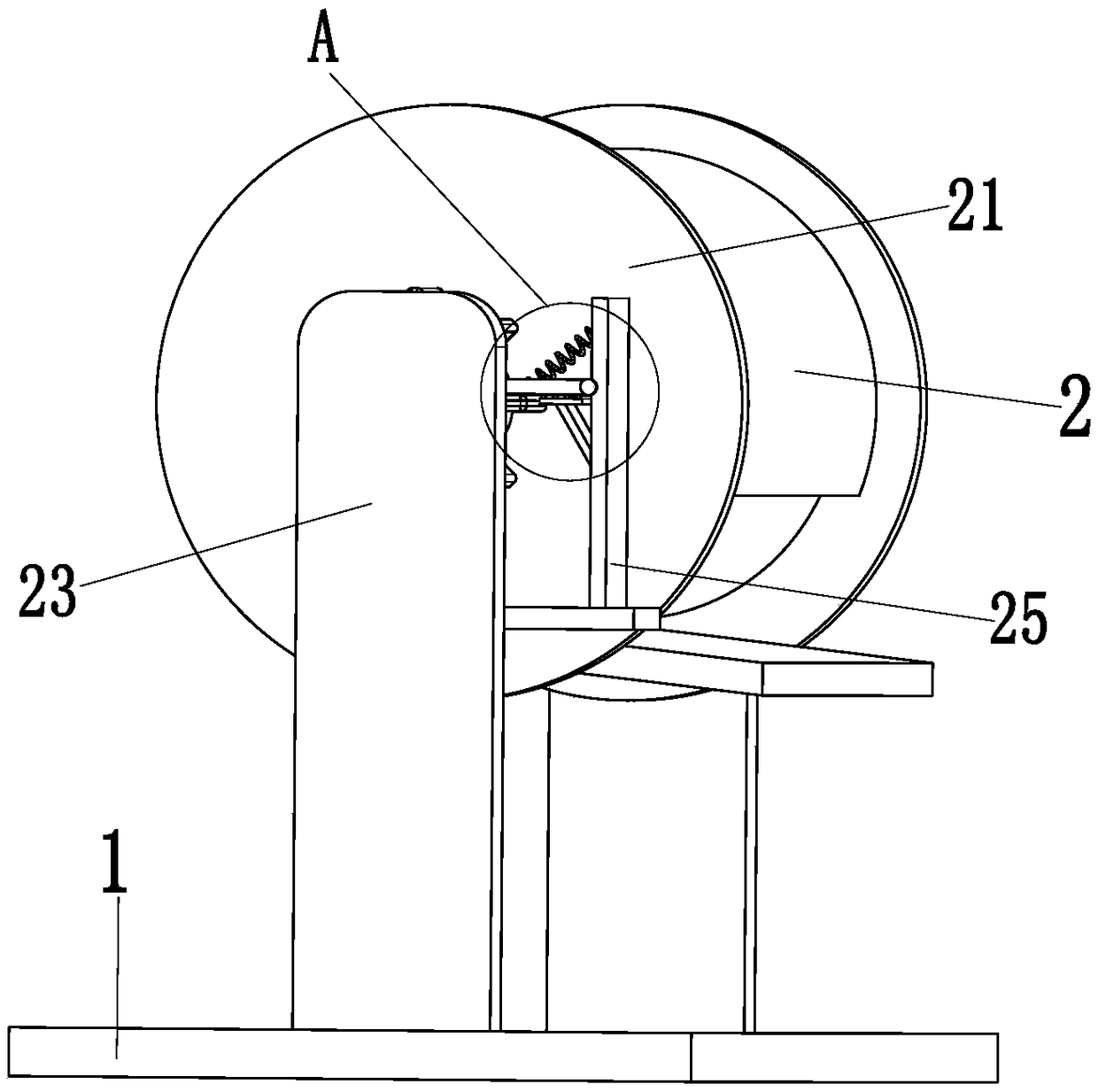

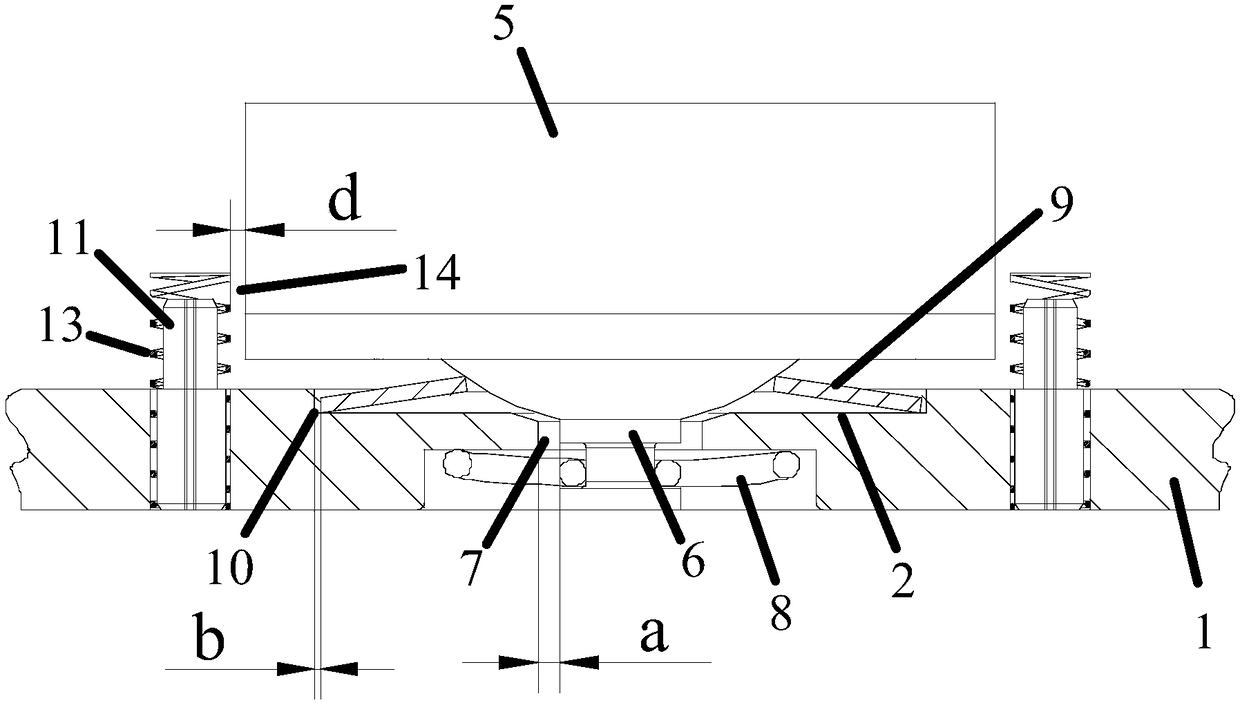

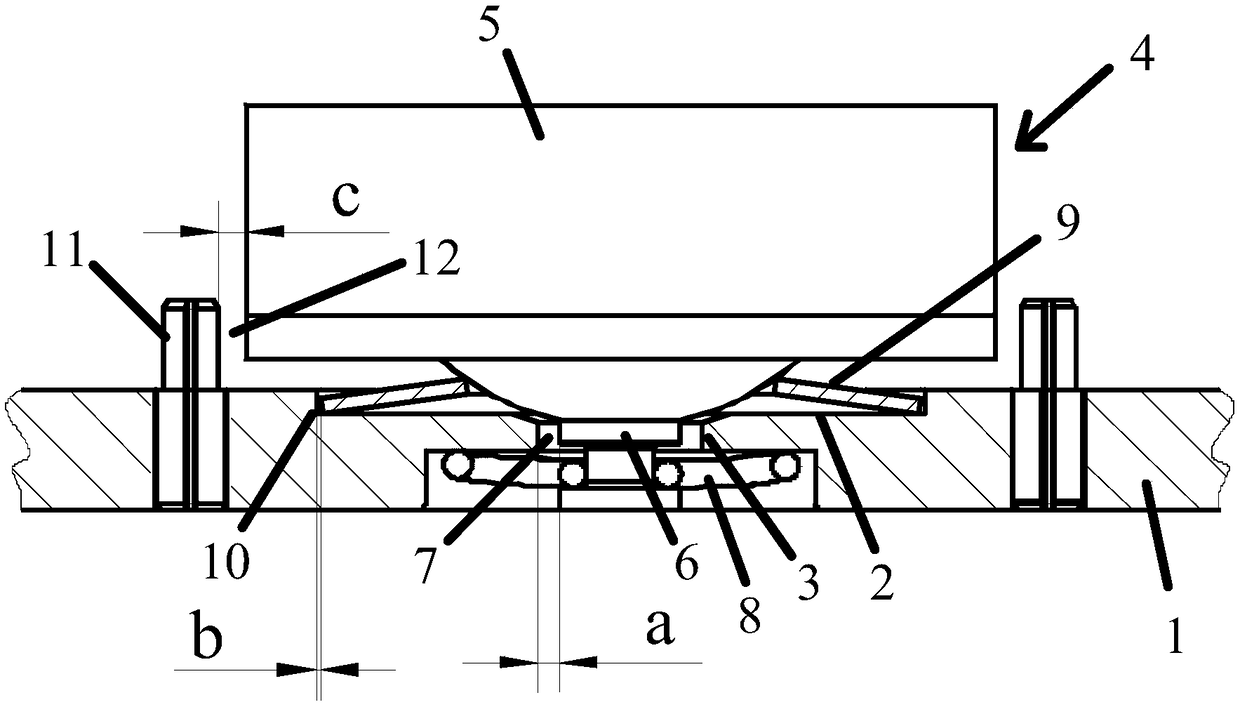

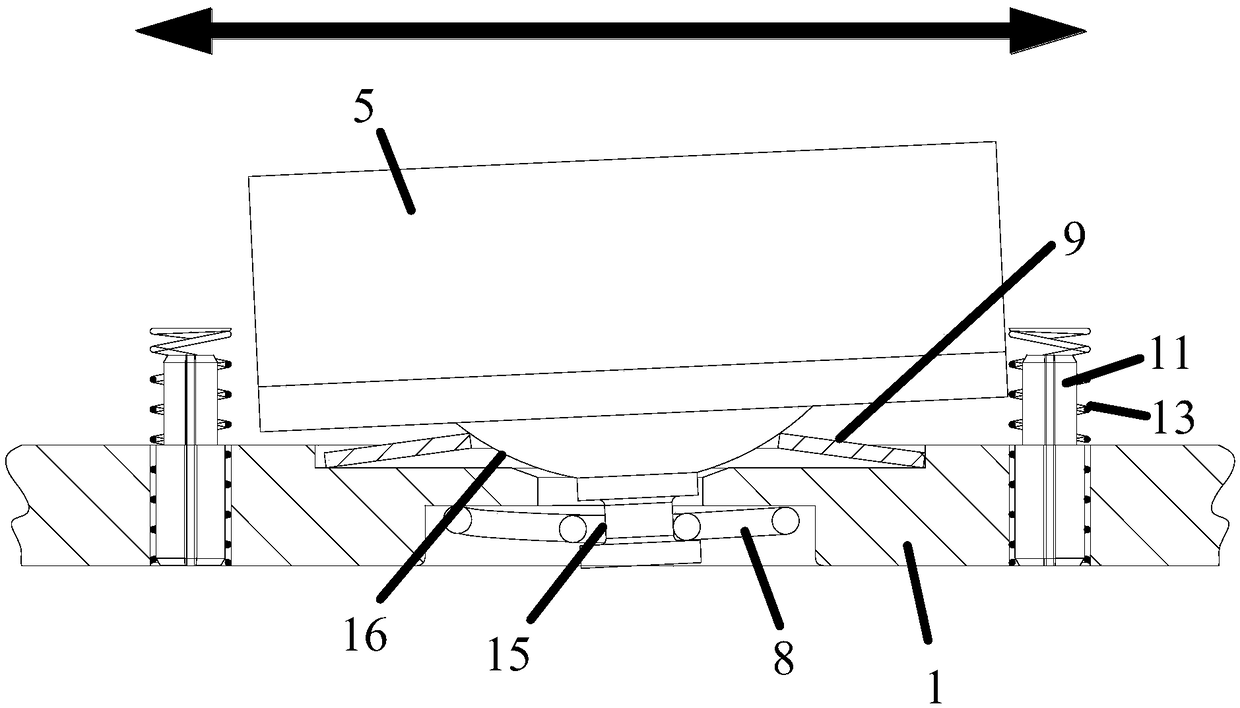

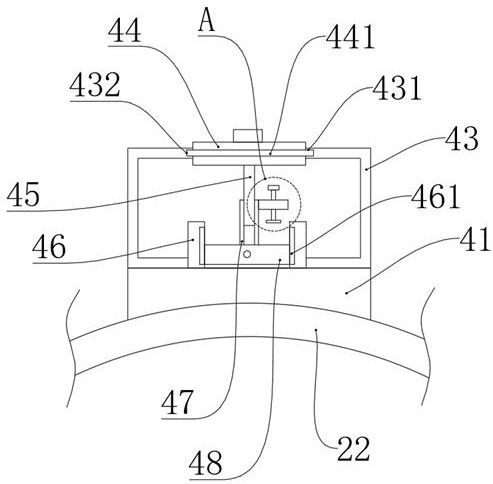

Monitoring equipment fixing device with vibration reducing function

InactiveCN104197166AImprove stabilityReduce friction lossNon-rotating vibration suppressionStands/trestlesStructural engineeringMonitor equipment

The invention discloses a monitoring equipment fixing device with a vibration reducing function. The monitoring equipment fixing device comprises a baseplate and two inclined baffle plates, wherein the two ends of the baseplate are connected with one side of a bent part; the other side of the bent part is connected with the ends of the baffle plates; an arched plate is connected between the two baffle plates; multiple rows of roller sets are arranged on the inner arc surface of the arched plate; the roller sets are multiple rollers spaced in the vertical direction of the top end of the arched plate; the monitoring equipment fixing device further comprises a plurality of hoops; and the hoops penetrate through the ends of the two baffle plates, and are contacted with the outer arc surface of the arched plate. The two inclined baffle plates and the baseplate form a saddle-shaped space structure; the arched plate seals an opening of the saddle-shaped space structure; and the ends of the hoops penetrating through the two baffle plates are positioned on the outer arc surface of the arched plate to increase the stability of a mounting base so as to prevent the damage of monitoring equipment caused by instability of a bracket in the use process.

Owner:CHENGDU BESTVISION TECH

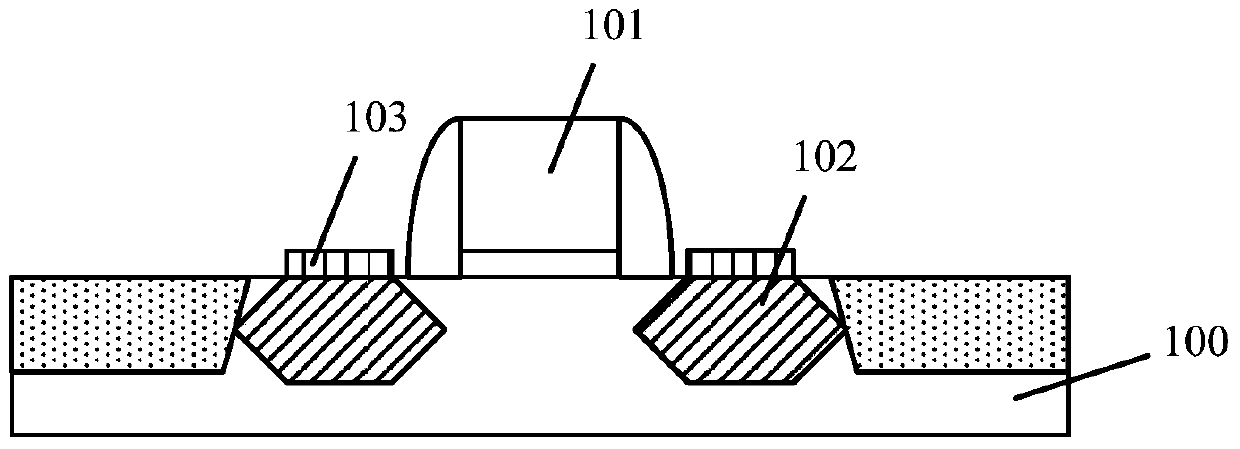

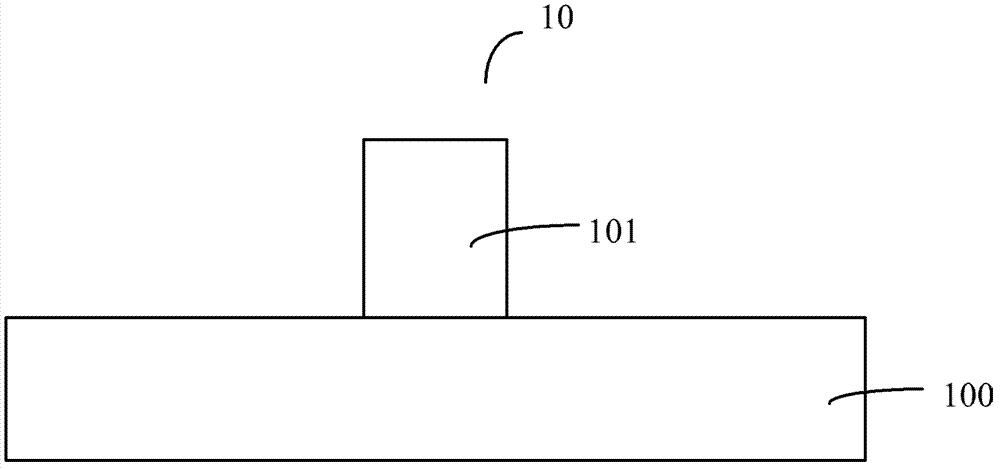

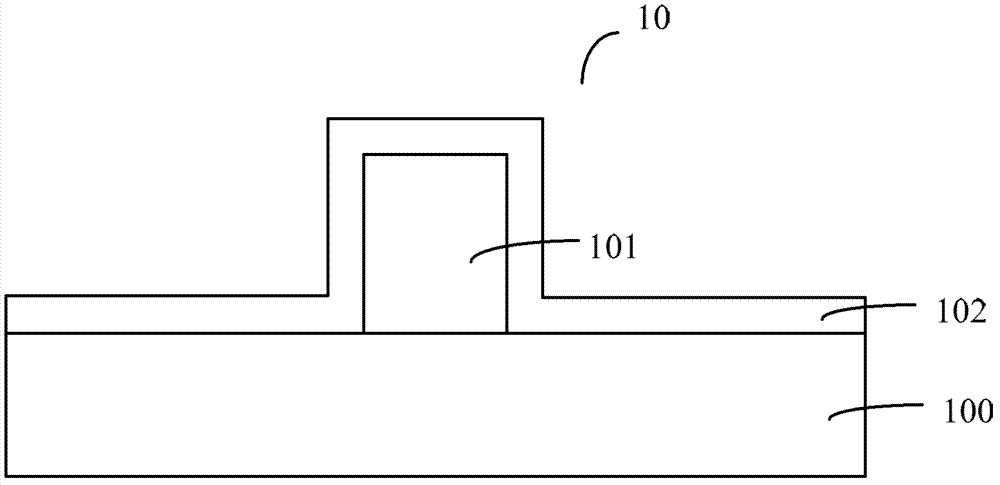

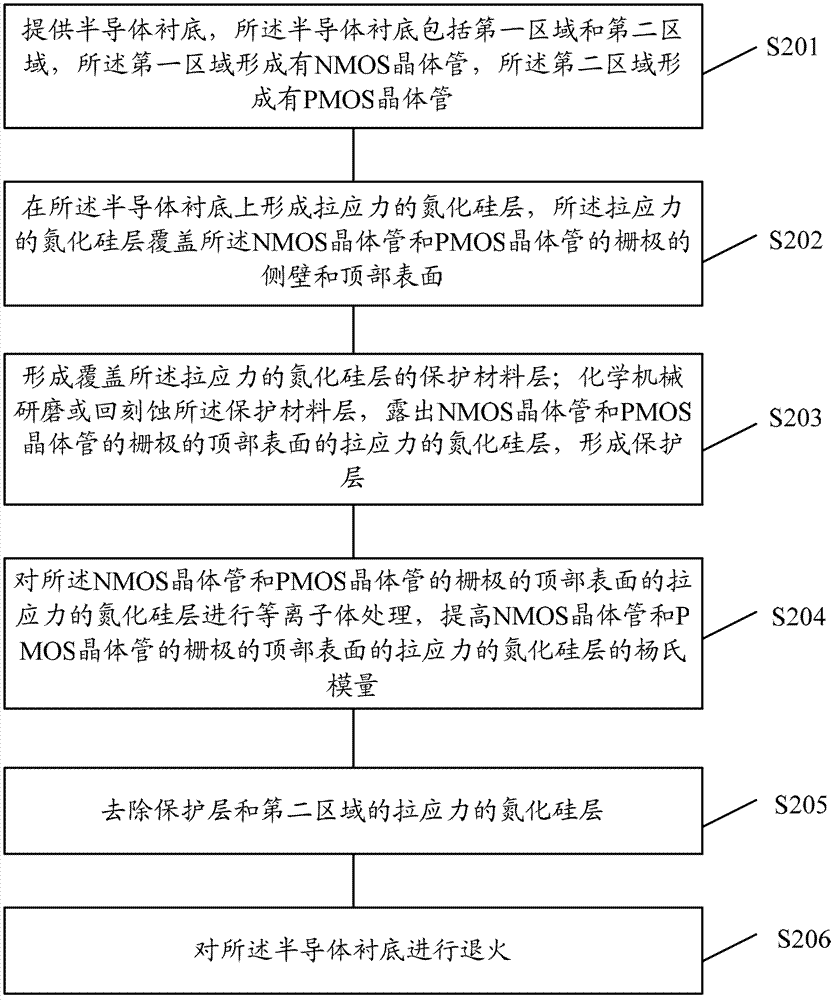

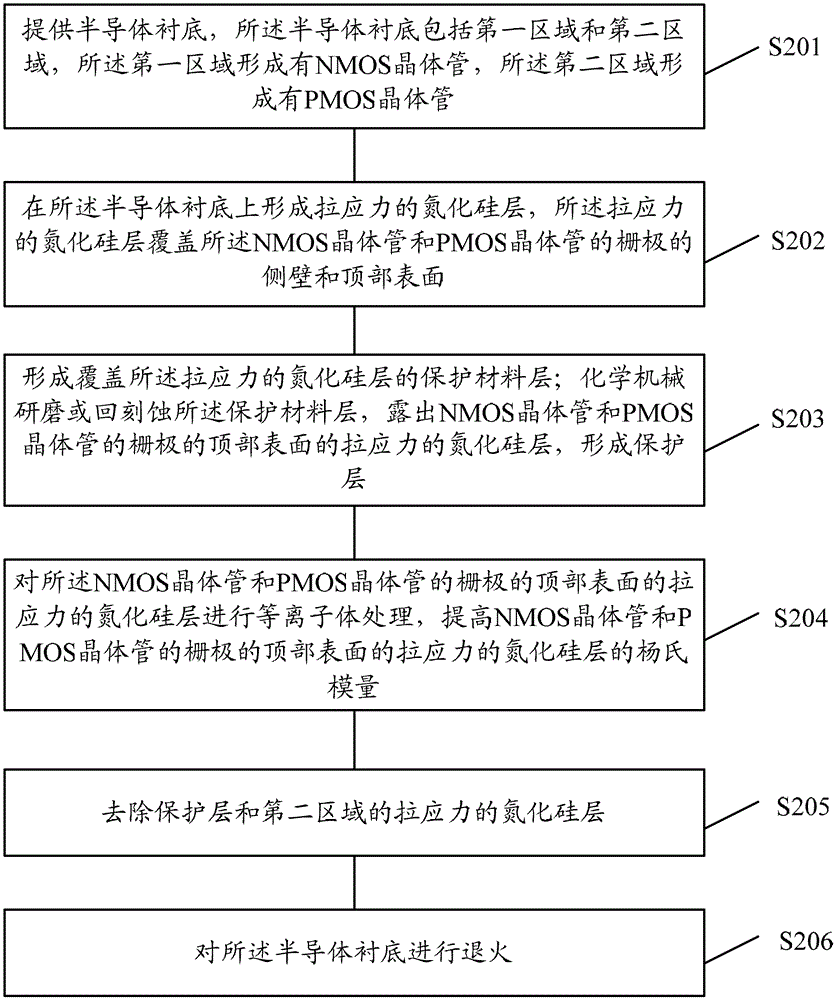

Methods for forming NMOS transistor and MOS transistor

ActiveCN103367155AIncrease stressHigh Young's modulusSemiconductor/solid-state device manufacturingSemiconductor devicesSilicon nitrideSemiconductor

Disclosed are methods for forming an NMOS transistor and an MOS transistor. The method for forming the NMOS transistor comprises: providing a semiconductor substrate, wherein the NMOS transistor is formed on the semiconductor substrate; forming a tension silicon nitride layer on the semiconductor substrate, wherein the tension silicon nitride layer covers the side wall and the top surface of the gate of the NMOS transistor; forming a protection layer on the tension silicon nitride layer, wherein the protection layer exposes the tension silicon nitride layer on the top surface of the gate of the NMOS transistor; performing plasma treatment on the tension silicon nitride layer on the top surface of the gate of the NMOS transistor for the purpose of enhancing the young modulus of the tension silicon nitride layer on the top surface of the gate of the NMOS transistor; and removing the protection layer. In the embodiment of the invention, the stress of the tension layer is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

NMOS transistor and method for forming the MOS transistor

ActiveCN103367155BIncrease stressHigh Young's modulusSemiconductor/solid-state device manufacturingSemiconductor devicesYoung's modulusProtection layer

Disclosed are methods for forming an NMOS transistor and an MOS transistor. The method for forming the NMOS transistor comprises: providing a semiconductor substrate, wherein the NMOS transistor is formed on the semiconductor substrate; forming a tension silicon nitride layer on the semiconductor substrate, wherein the tension silicon nitride layer covers the side wall and the top surface of the gate of the NMOS transistor; forming a protection layer on the tension silicon nitride layer, wherein the protection layer exposes the tension silicon nitride layer on the top surface of the gate of the NMOS transistor; performing plasma treatment on the tension silicon nitride layer on the top surface of the gate of the NMOS transistor for the purpose of enhancing the young modulus of the tension silicon nitride layer on the top surface of the gate of the NMOS transistor; and removing the protection layer. In the embodiment of the invention, the stress of the tension layer is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

A telescopic insert type mobile socket

ActiveCN104993267BSimple structureReduce volumeCoupling contact membersElectrical conductorEngineering

Owner:SHANUTEC (SHANGHAI) CO LTD

Monitoring equipment fixture with shock absorption

InactiveCN104197166BImprove stabilityReduce friction lossNon-rotating vibration suppressionStands/trestlesSpatial structureInstability

The invention discloses a monitoring equipment fixing device with a vibration reducing function. The monitoring equipment fixing device comprises a baseplate and two inclined baffle plates, wherein the two ends of the baseplate are connected with one side of a bent part; the other side of the bent part is connected with the ends of the baffle plates; an arched plate is connected between the two baffle plates; multiple rows of roller sets are arranged on the inner arc surface of the arched plate; the roller sets are multiple rollers spaced in the vertical direction of the top end of the arched plate; the monitoring equipment fixing device further comprises a plurality of hoops; and the hoops penetrate through the ends of the two baffle plates, and are contacted with the outer arc surface of the arched plate. The two inclined baffle plates and the baseplate form a saddle-shaped space structure; the arched plate seals an opening of the saddle-shaped space structure; and the ends of the hoops penetrating through the two baffle plates are positioned on the outer arc surface of the arched plate to increase the stability of a mounting base so as to prevent the damage of monitoring equipment caused by instability of a bracket in the use process.

Owner:CHENGDU BESTVISION TECH

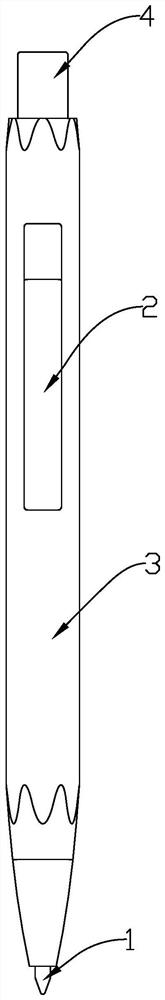

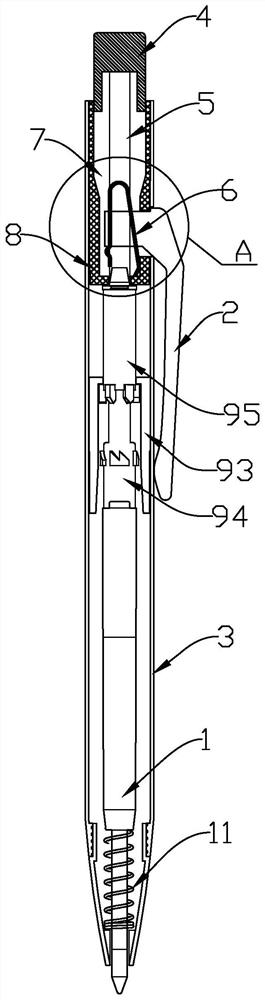

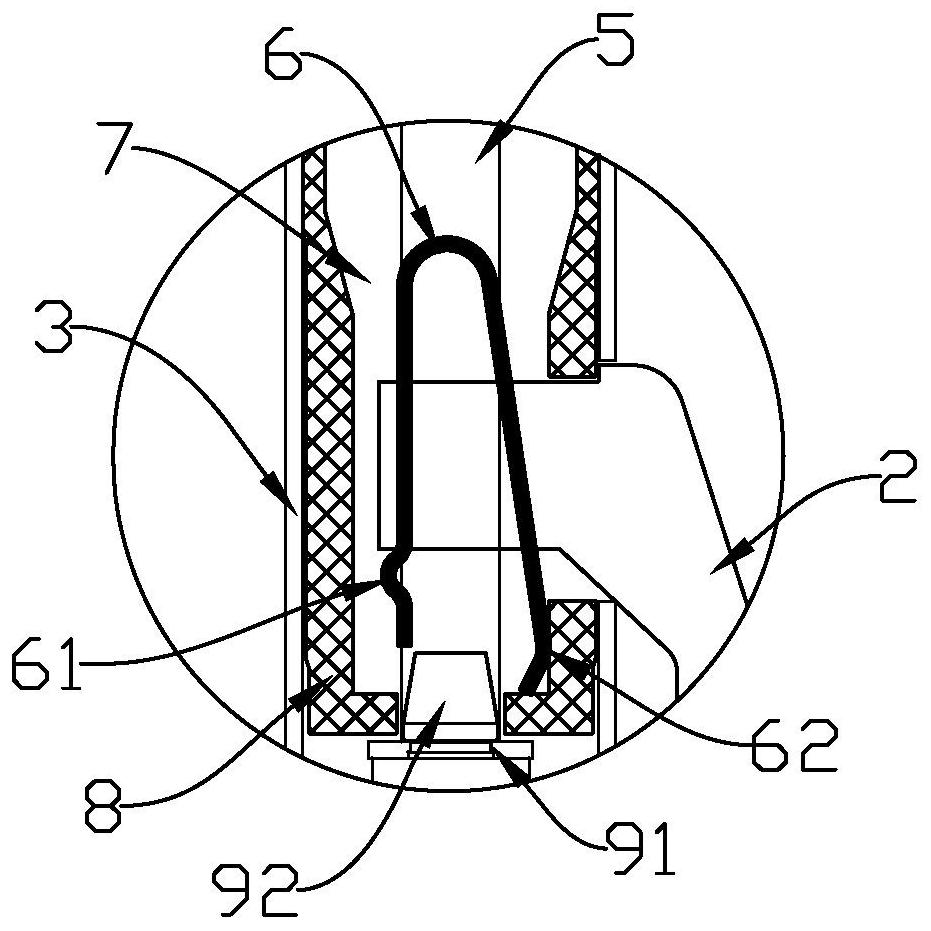

Press-type writing pen

ActiveCN110561949BAchieve scaleSolve the installationWriting implement attachmentsWriting unitsEngineeringMechanical engineering

The invention discloses a novel push type writing pen which at least comprises a refill, a pen holder, a pressing cap, an elastic part, a pen clip housing, a pen clip elastic sheet, a joining elasticsheet, a bouncing mechanism and a pen clip, wherein the pen holder covers the outer side of the refill and a pen clip mounting hole is formed in the upper part of the pen holder; the pressing cap is movably arranged on the top of the pen holder in a sleeving manner; one end of the elastic part leans against the refill while the other end of the elastic part leans against the pen holder; the pen clip housing is located in the pen holder axially; the pen clip elastic sheet is arranged in the pen clip housing; the joining elastic sheet penetrating from the bottom of the pen clip housing is connected to the pressing cap; the bouncing mechanism is connected to a locking hole of the joining elastic sheet; the pen clip, successively penetrating the pen clip mounting hole and an opened hole partially, is arranged on the pen clip elastic sheet in a sleeving manner and is in butt joint to the pen clip elastic sheet, and the end part of the pen clip leans against the outer wall of the pen holder;and when an external force is applied to the pen clip and the end part of the pen clip is tend to be far away from the pen holder, the pen clip elastic sheet can deform elastically to provide an action force for restoring the pen clip. The novel push type writing pen is simple in structural design and simple to assemble. The pen clip which is elastic and forceful can fit clamped articles of different thicknesses, and the pen clip which is used for a long time does not lose efficiency.

Owner:桐庐优德文化创意有限公司

Piezoelectric Valveless Micropump Sucker Based on Parallel Compliant Mechanism

InactiveCN103671462BIncreased shear strengthIncrease elasticitySuction cupsVehiclesCompliant mechanismEpoxy

The invention discloses a piezoelectric valveless micropump suction cup based on a parallel connection compliant mechanism. The piezoelectric valveless micropump suction cup based on the parallel connection compliant mechanism comprises a monocrystalline silicon substrate, a copper-based composite film, the compliant mechanism and a piezoelectric stack driver. The compliant mechanism is provided with a deformation displacement input part, a deformation displacement output part and a locating groove. The piezoelectric stack driver is fixedly clamped at a hollowed-out position in the upper portion of the deformation displacement input part and is closely attached to the deformation displacement input part. The copper-based composite film located on the upper layer and the monocrystalline silicon substrate located on the lower layer are bonded together and assembled through epoxy structure bonding glue to form a thin film micropump. The thin film micropump is clamped into the locating groove of the compliant mechanism and is sealed in a bonding mode. The lower end face of the deformation displacement output part is attached to the upper plane of the copper-based composite film in a bonding mode. The compliant mechanism amplifies unidirectional deformation displacement generated after the piezoelectric stack driver is powered on, and then transmits the unidirectional deformation displacement to the copper-based composite film to drive the thin film micropump to operate, gas in an adsorption cavity formed in the lower portion of the monocrystalline silicon substrate is extracted, and negative pressure of the suction cup is generated. The piezoelectric valveless micropump suction cup based on the parallel connection compliant mechanism is small in size, light in weight, free of noise, and capable of being used as an adsorption device of a wall-climbing robot.

Owner:SHANGHAI JIAOTONG UNIV

Solar panel device with snow removal and protection function

ActiveCN112511098AExtended service lifeAvoid massive snowPhotovoltaicsPhotovoltaic energy generationPhysicsEngineering

The invention relates to the technical field of solar panels, in particular to a solar panel device with snow removal and protection functions. The device comprises a device body, and is characterizedin that the device body comprises two first shells and a solar panel, the solar panel is fixed between the two first shells, an inlet / outlet is formed in the upper half part of the opposite side of each first shell; the device further comprises a shielding mechanism, the shielding mechanism comprises two first fixing rods, four first gears, two chains, a moving assembly and a plurality of snow removing assemblies, the first fixing rods are located in the corresponding first shells, the two ends of each first fixing rod are fixed to the two opposite sides of the inner wall of the correspondingfirst shell, the two first gears are symmetrically and rotationally arranged on the outer circumferential faces of the corresponding first fixing rods in a sleeving mode, and the multiple snow removing assemblies shield the solar panel. The solar panel device has the advantages that the possibility that the solar panel is pressed by accumulated snow is avoided, and the service life of the solar panel is prolonged.

Owner:山东天予嘉蓝环保科技有限公司

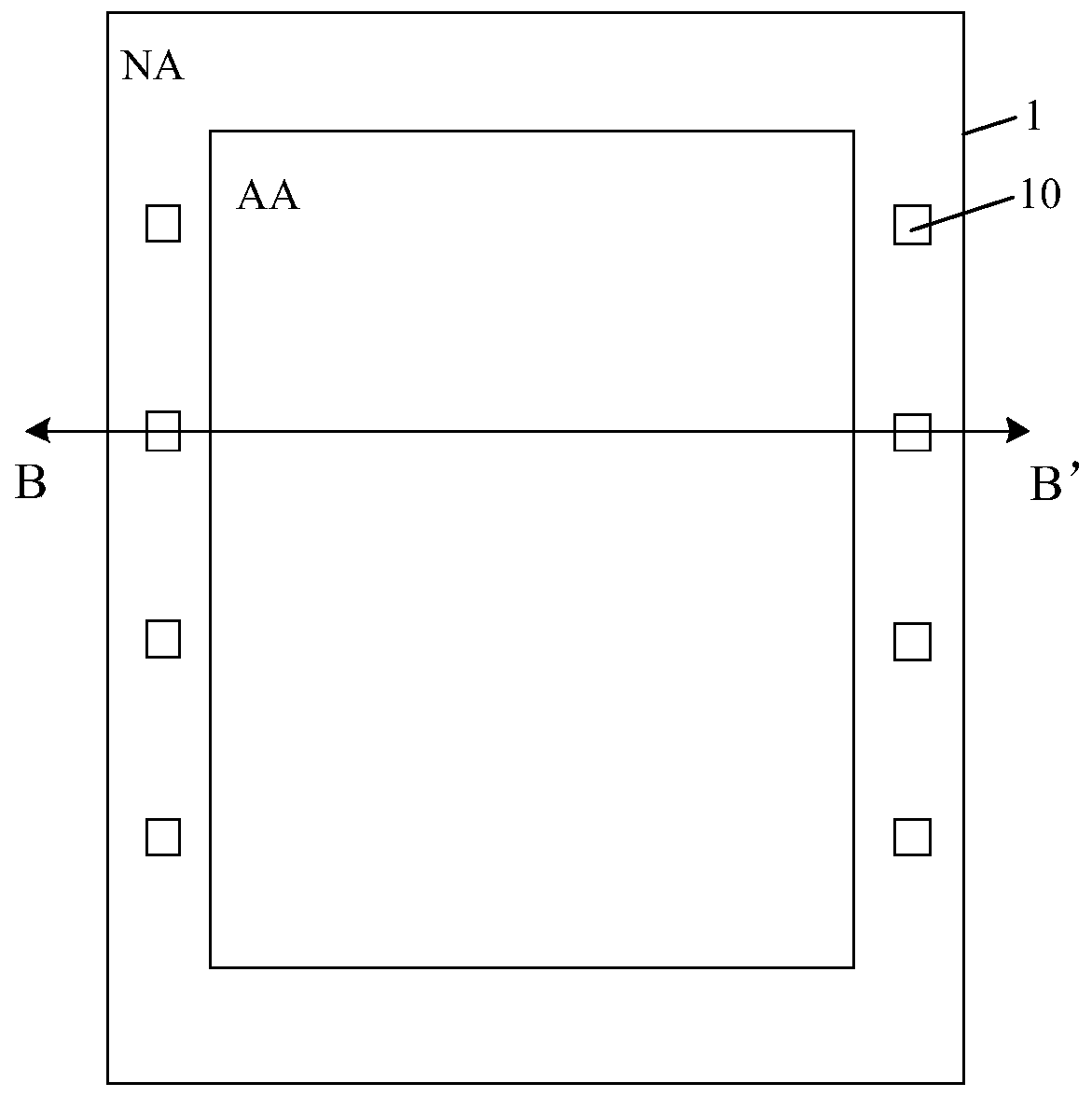

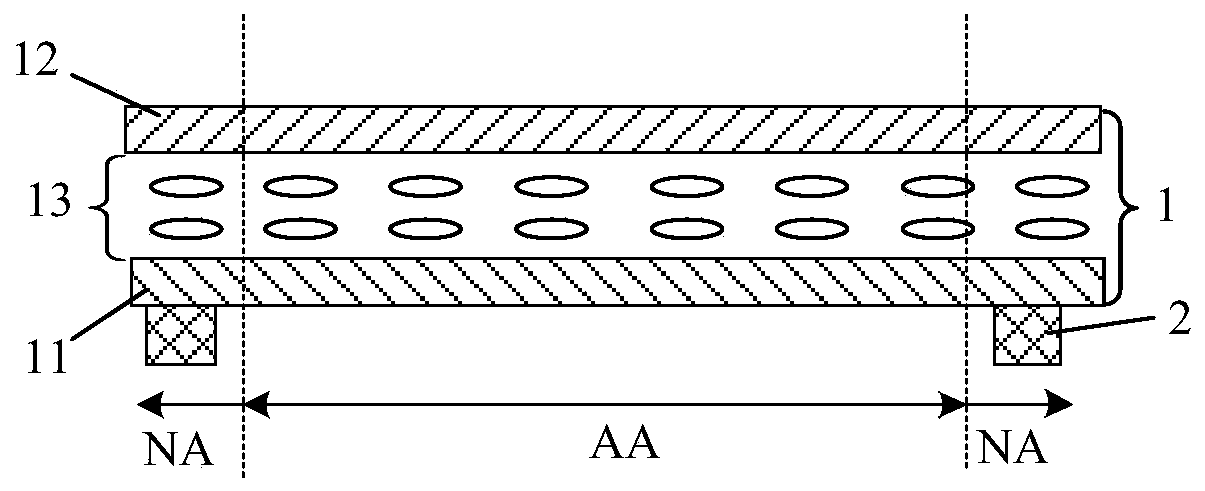

a display device

ActiveCN107193427BDeformation will not occurHigh precisionDigital data processing detailsInput/output processes for data processingComputer hardwareMedicine

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com