A hanging mobile socket

A socket and plug connection technology, applied in the direction of two-part connection devices, contact parts, electrical components, etc., can solve problems such as difficulty in accurately predicting the installation position and quantity of socket holes, deformation of elastic conductors of power connection guide rails, and complicated wiring in walls. To achieve the effect of easy plug-in access, small footprint, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

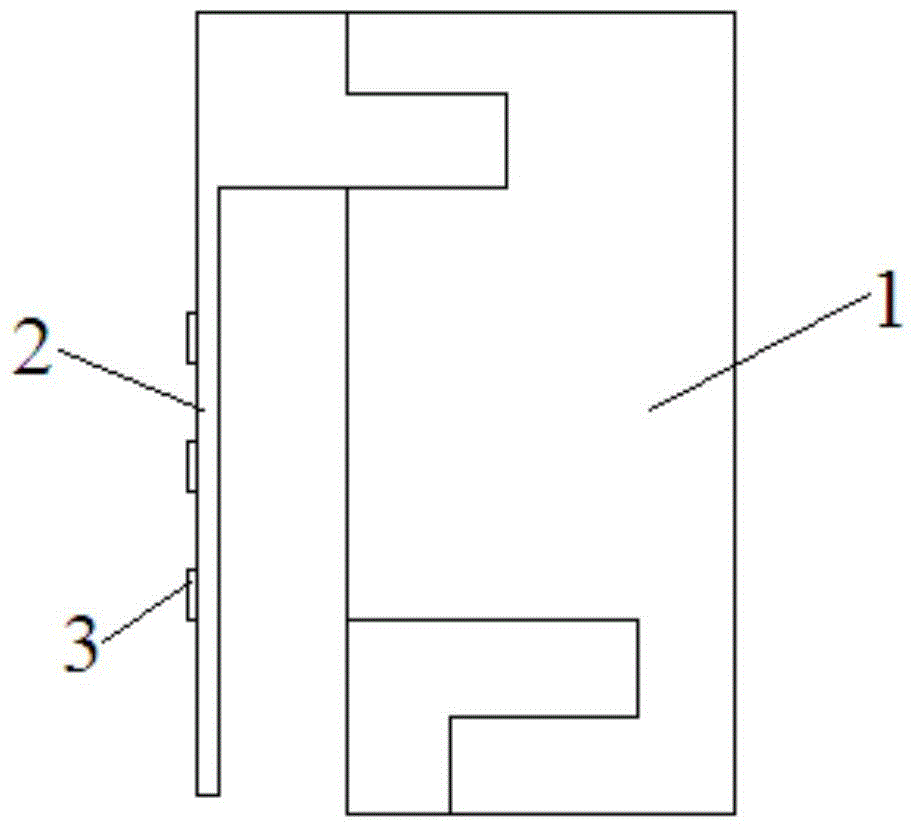

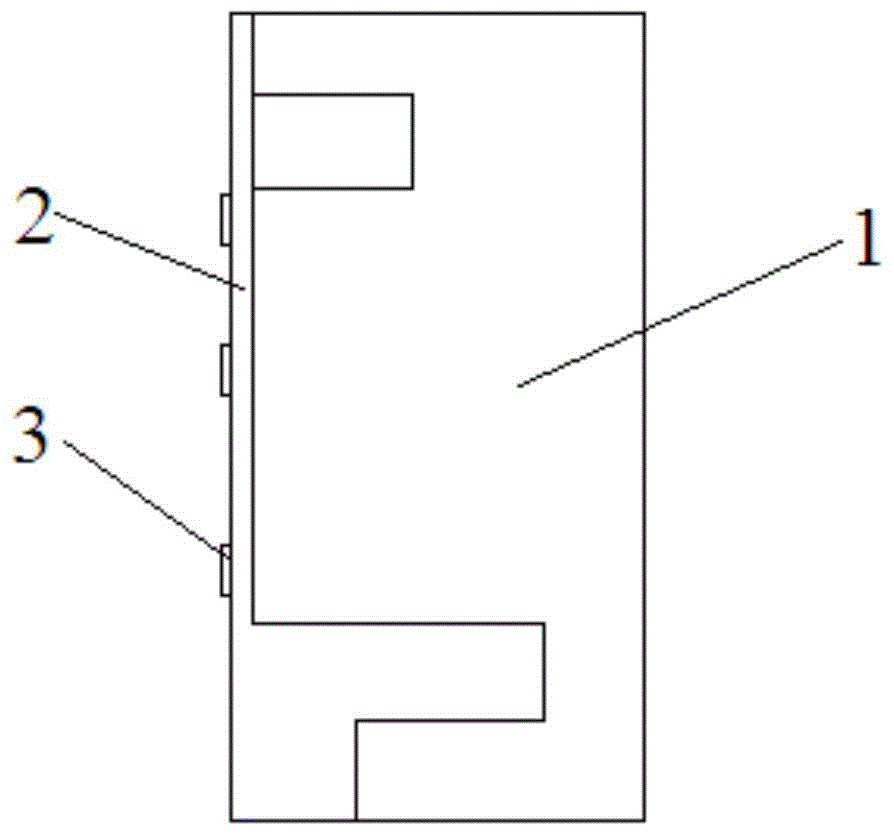

[0052] A hanging mobile socket such as Figure 1 ~ Figure 2 As shown, it includes a shell 1 and a hanging piece 2. At least one side of the shell 1 is provided with a jack connected to the plug, and a chuck conductive sheet is arranged inside the jack, and the hanging piece 2 is hung on the outside of the shell 1, and The surface of the coupon 2 is provided with an elastic conductor contact 3 for conducting the power supply. In the working state, the elastic conductor contact 3 is in conduction with the chuck conductive sheet.

[0053] Such as image 3 , Figure 4 As shown, there is a connecting groove 5 on the back of the housing 1, and an inner contact 6 is arranged in the connecting groove 5, and the inner contact 6 is connected and conducted with the chuck conductive sheet inside the housing, and a retracting groove is also provided on the back of the housing 1. 9. After the connector 7 is inserted into the retracting groove 9, the hanging piece 2 is closely attached to ...

Embodiment 2

[0057] Such as Figure 7 ~ Figure 9 As shown, the difference from Embodiment 1 is that the jack used to connect the plug and the conductive sheet of the clip provided inside the jack are set as an slug, and the slug can be replaced by a power-taking unit, which includes Routers, sensors, alarms, detectors, cameras, chargers or converters.

Embodiment 3

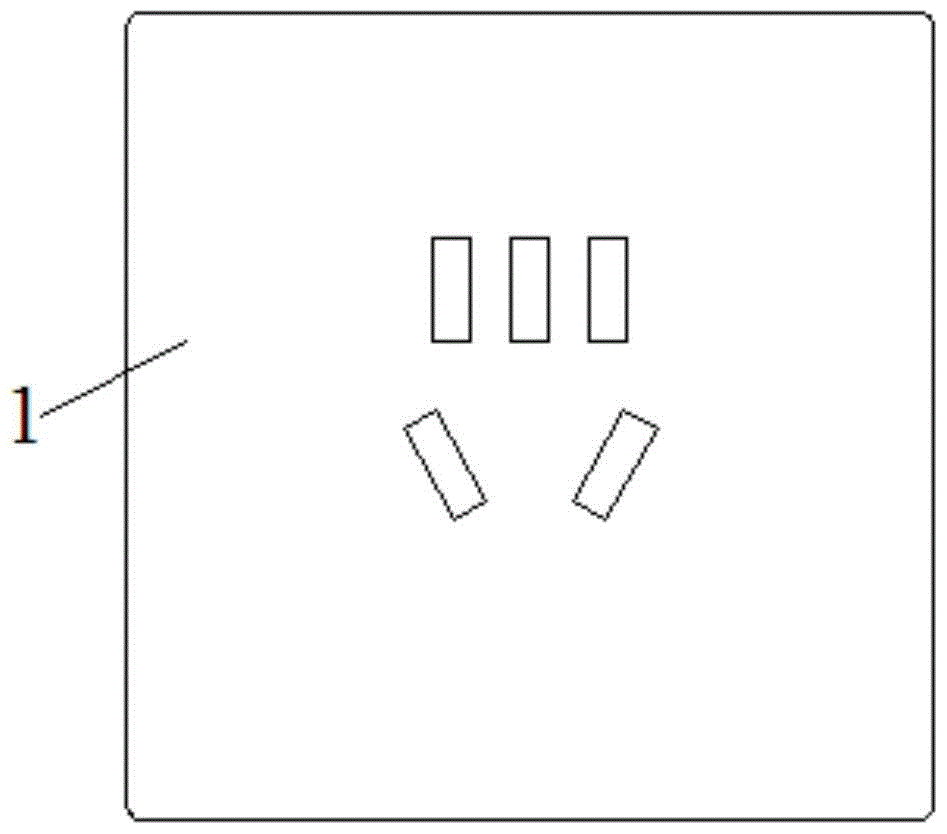

[0059] A hanging mobile socket such as Figures 12 to 14 As shown, it includes a shell 1 and a hanging piece 2. At least one side of the shell 1 is provided with a jack connected to the plug, and a chuck conductive piece 4 is arranged inside the jack. In addition, the surface of the coupon 2 is provided with an elastic conductor contact 3 for conducting the power supply, and in the working state, the elastic conductor contact 3 is in conduction with the chuck conductive sheet. The housing 1 is composed of a front cover 14 and a rear cover 15. The notch 12 is opened on the rear cover 15. The upper end of the hanging piece 2 is provided with a connecting plate 10. The rear end of the connecting plate 10 is connected to the baffle plate 11, and the connecting plate 10 is plugged in. In the notch 12, the baffle plate 11 is located inside the housing 1, the hanger 2 is located outside the housing 1, the hanger 2 is embedded with a conductive sheet 16, one end of the conductive shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com