Floating type brake pad

A brake pad, floating technology, applied in the direction of brake parts, brake types, brake components, etc., can solve problems such as affecting the braking effect, breaking, and deformation of connecting parts, and achieve the effect of improving the braking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

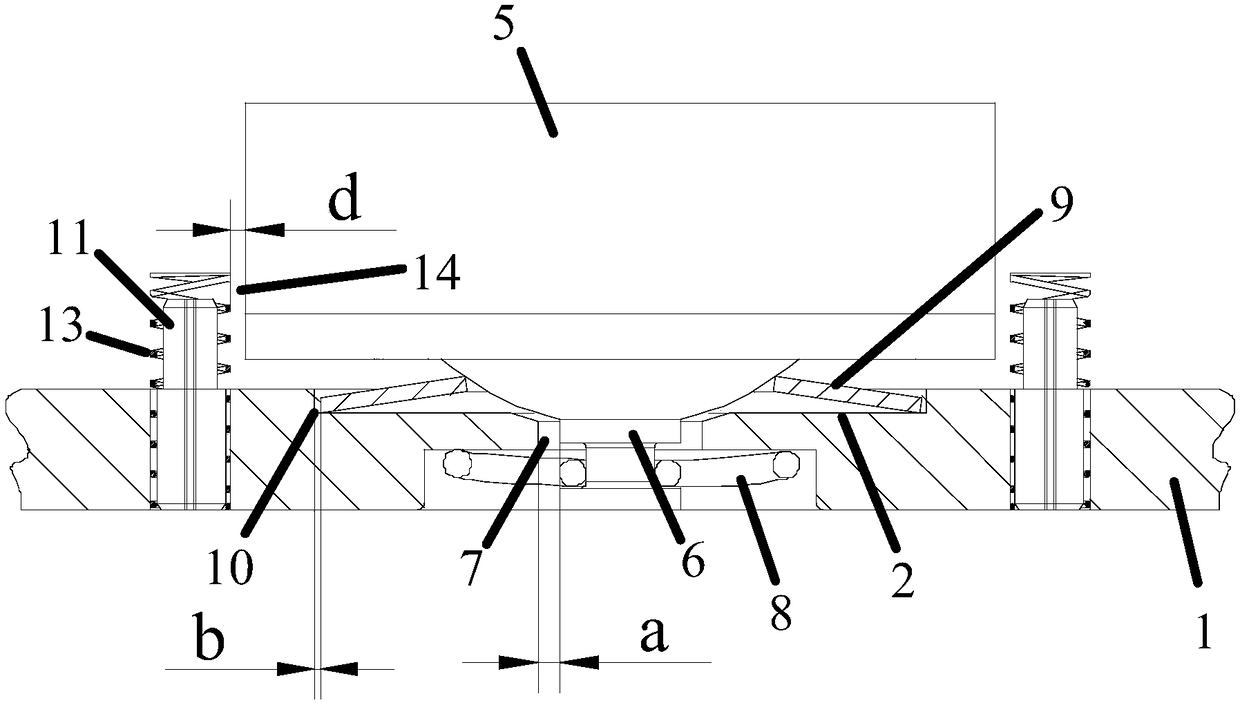

[0041] A floating brake pad is described, such as figure 1 and image 3 shown, which includes:

[0042] Brake back plate 1, said brake back plate 1 is a horseshoe-shaped structure on which a spot-faced plane 2 of a circular structure and a positioning hole 3 of a cylindrical structure are formed;

[0043] The friction body 4 includes a friction part 5, a positioning part 6 inserted into the positioning hole 3, and a spherical support part arranged between the friction part 5 and the positioning part 6 and facing the brake pad back plate 1 16. The positioning part 6 is a cylindrical structure extending from the friction part 5 to the positioning hole 3 and matching with the positioning hole 3. There is a gap between the positioning part 6 and the positioning hole 3 a first relative gap 7 with a relative distance a;

[0044] Elastic support 9, elastic support 9 is a disc-shaped sheet structure connected with the spherical support 16, the elastic support 9 is installed in the ...

Embodiment 2

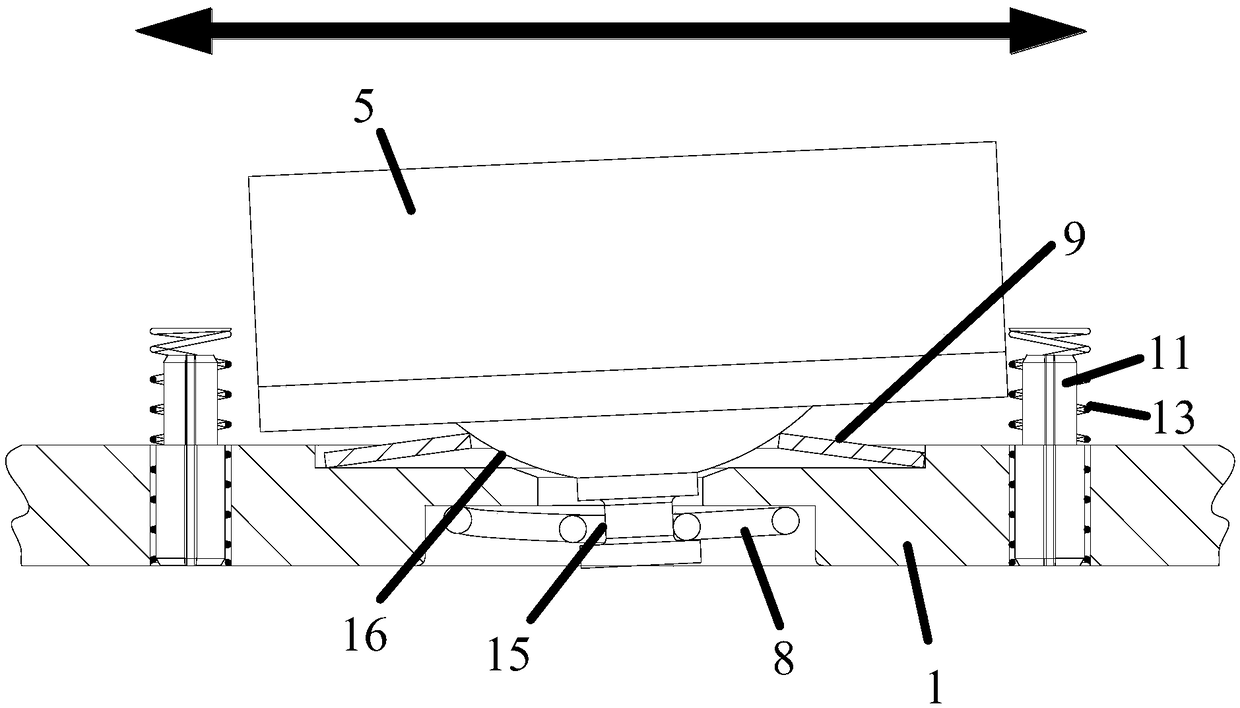

[0050] The difference between this embodiment and Embodiment 1 is that the outer contour edge of the elastic support member 9 abuts and connects with the inner side wall of the spot facing plane 2, the distance b of the second relative gap 10 is 0, and the first The distance a of the relative gap 7 is greater than the distance d of the fourth relative gap 14 .

Embodiment 3

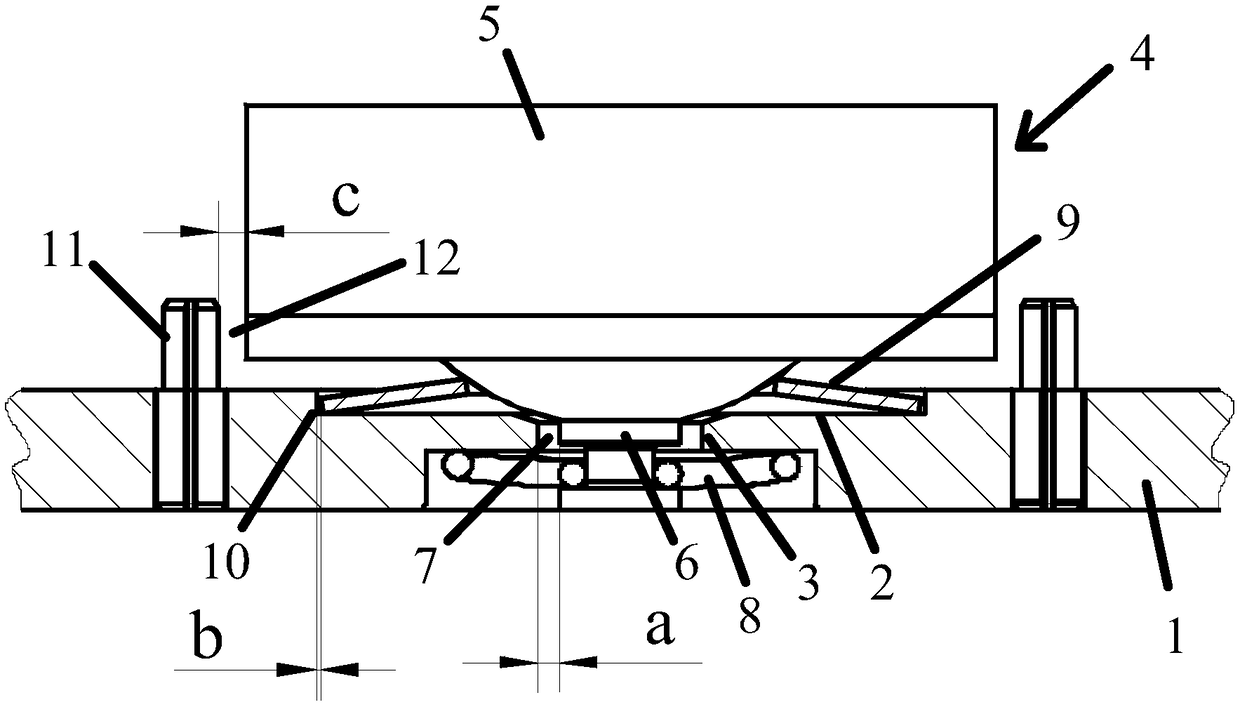

[0052] The difference between this embodiment and embodiment 1 is that, as figure 2 as shown,

[0053] The anti-rotation member 11 is a columnar structure made of spring stainless steel, which is arranged on the brake pad back plate 1 so as to limit the rotation direction of the friction body 4 and control the position of the friction body 4 in the horizontal direction. The position is limited by offset, and there is a third relative gap 12 with a relative distance c between the anti-rotation member 11 and the friction part 5; the distance a of the above-mentioned first relative gap 7 is greater than the distance c of the third relative gap 12 , and the spacing c of the third relative gap 12 is greater than the spacing b of the second relative gap 10, and the hardness value of the compression sleeve 13 is smaller than the hardness value of the anti-rotation member 11, and the anti-rotation member The hardness value of 11 is greater than the hardness value of the elastic supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com