Production process of wood grain and stone grain imitating mosaic ceramic tiles

A production process, mosaic technology, applied in printing process, printing of special varieties of printed matter, decorative arts, etc., can solve the problems of low fidelity, poor fidelity of mosaic tiles, etc., and achieve the effect of improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

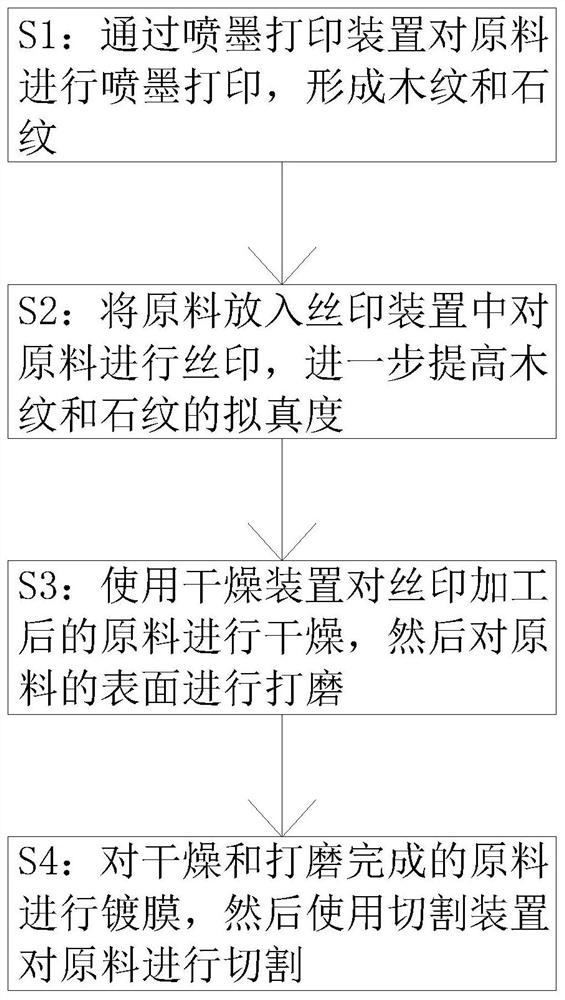

[0025] see figure 1 Shown, a kind of imitation wood grain, stone pattern mosaic ceramic tile production process, this production process comprises the following steps:

[0026] S1: Carry out inkjet printing on raw materials by inkjet printing device to form wood grain and stone grain;

[0027] S2: Put the raw materials into the silk screen printing device to perform silk screen printing on the raw materials to further improve the fidelity of wood grain and stone grain;

[0028] S3: Use a drying device to dry the raw material after silk screen printing, and then polish the surface of the raw material;

[0029] S4: Coating the dried and polished raw materials, and then cutting the raw materials with a cutting device.

[0030] In S1, the raw materials are first cleaned and polished before inkjet printing, so as to prevent impurities such as scratches and dust on the raw materials from affecting the inkjet effect.

[0031] The raw material in the S1 is PVC and PET composite boa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com